Protect margins and shelf space with consumer goods ERP software, uniting shelf-life control, trade promotions, and retailer compliance into one system built for fast-moving food packaging goods companies.

From expiry control to trade spend visibility, ERP tackles food CPG’s toughest daily battles.

Adjust production schedules instantly when big-box retailers change forecasts, preventing excess inventory and costly food waste. ERP keeps operations nimble and profitable.

Monitor shelf-life down to the batch, ensuring short-dated products don’t slip into shipments. ERP reduces spoilage losses and retailer chargebacks.

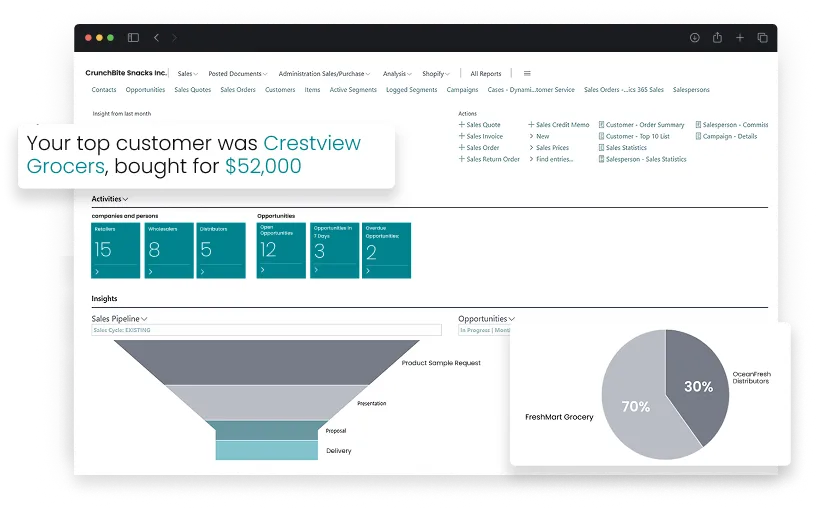

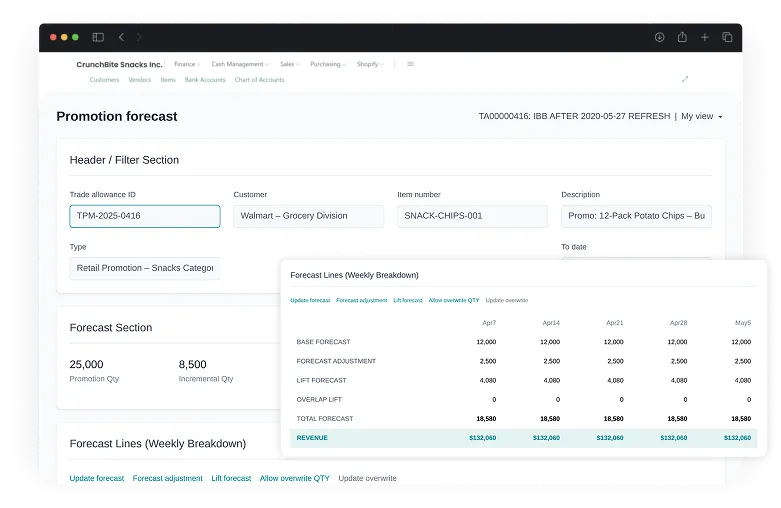

Eliminate costly surprises by tracking every retailer deduction, promotion, and allowance, with clear ROI insights on each campaign.

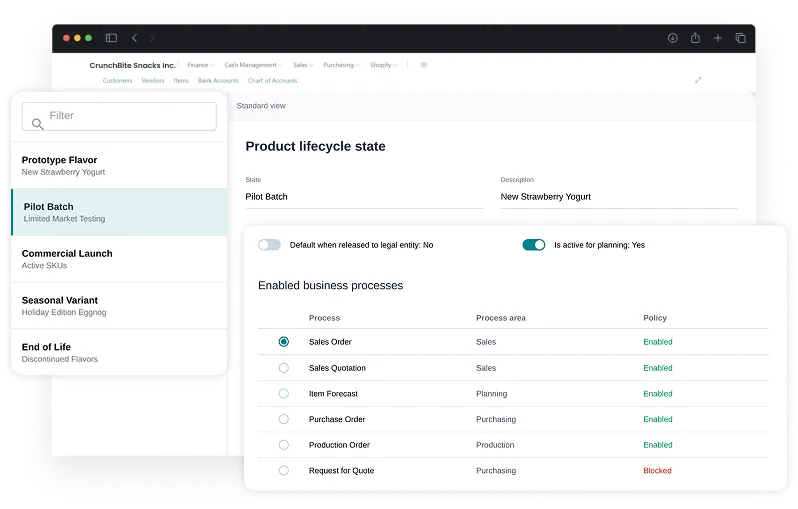

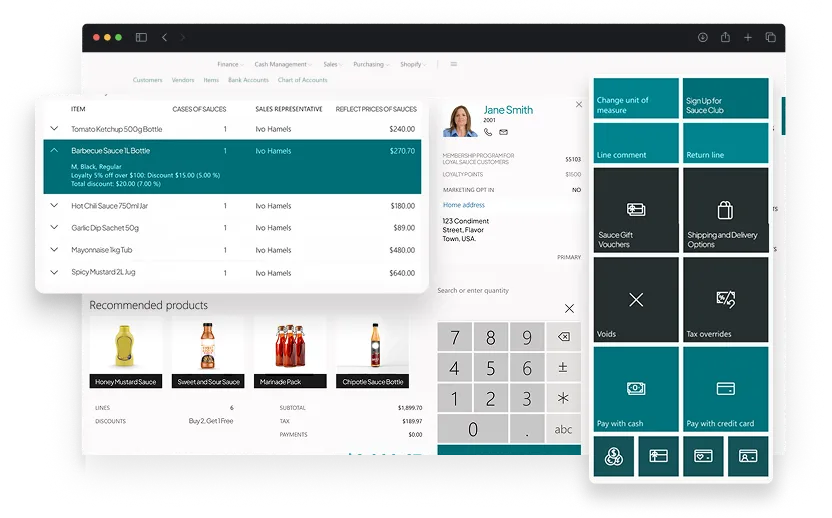

Easily manage endless flavors, seasonal packs, and retailer-specific packaging so every product leaves your facility accurate and compliant.

Anticipate demand swings driven by holidays, promotions, or consumer fads. ERP forecasting balances production, inventory, and distribution with market realities.

Avoid chargebacks and delays by meeting every retailer’s labeling, EDI, and routing guide requirements the first time, every time.

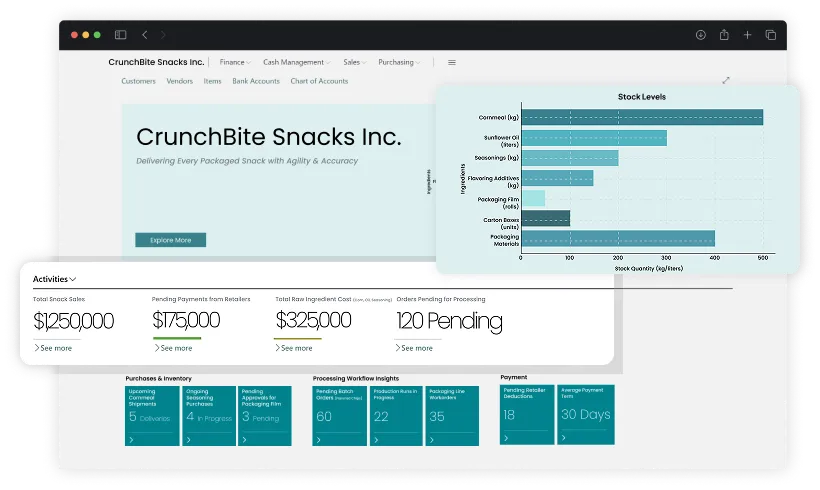

Achieve end-to-end oversight in packaged food operations using ERP solutions for the consumer goods industry, purpose-built for growth.

Bring new packaged foods to market faster while ensuring compliance, cost control, and consumer appeal.

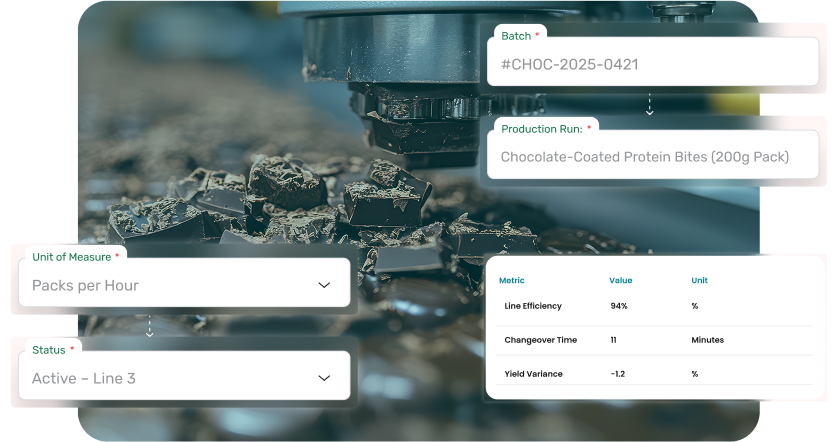

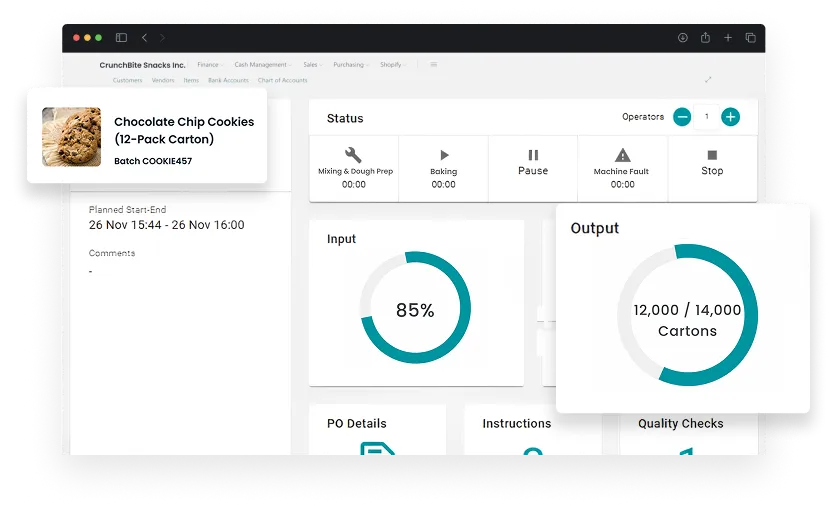

Blend, batch, and track ingredients with allergen visibility while running efficient lines for multiple food SKUs.

Keep shelves stocked and waste minimized by balancing demand, supplier reliability, and perishable inventory flow.

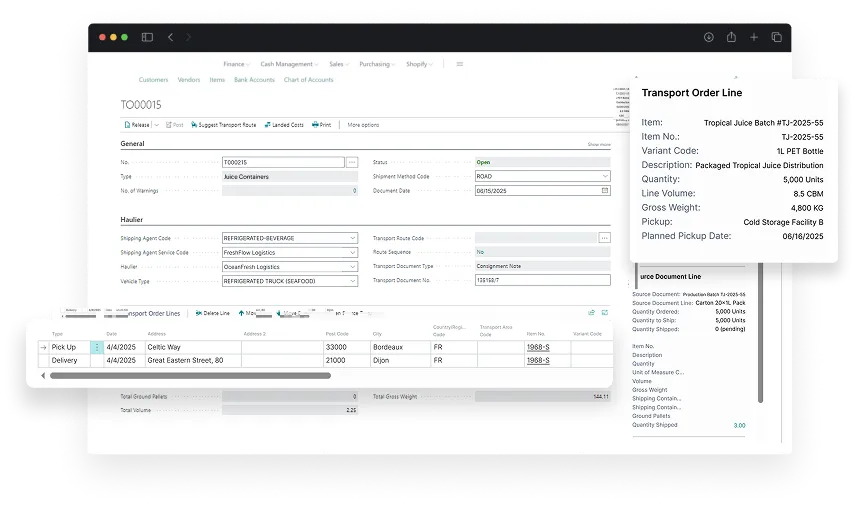

Use consumer goods distribution ERP software to keep packaging runs, expiry dates, and pallet configurations retail-ready.

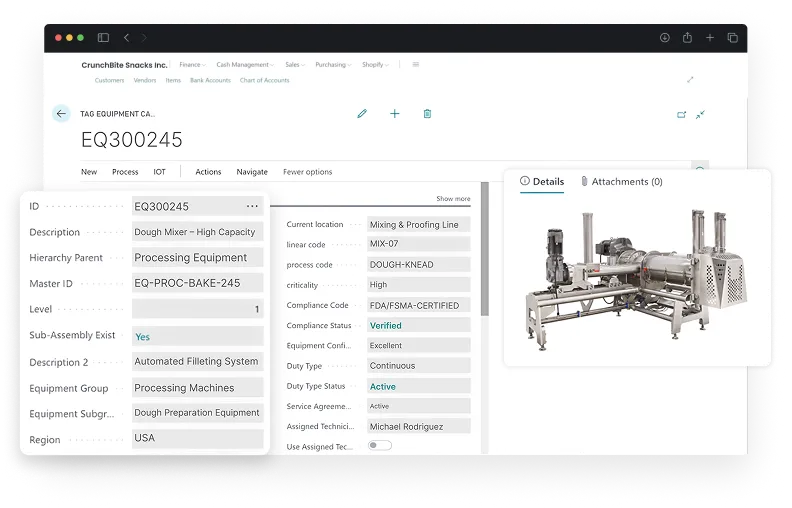

Reduce downtime and compliance risks by maintaining production assets to food-grade safety and efficiency standards.

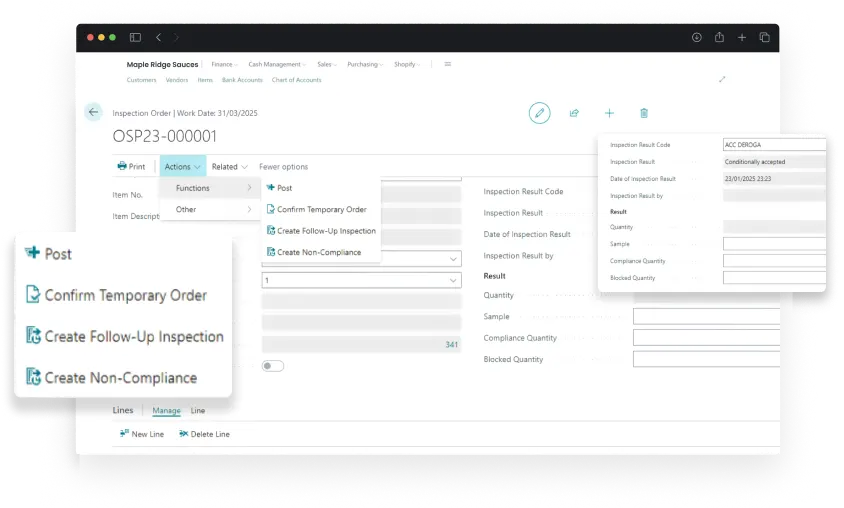

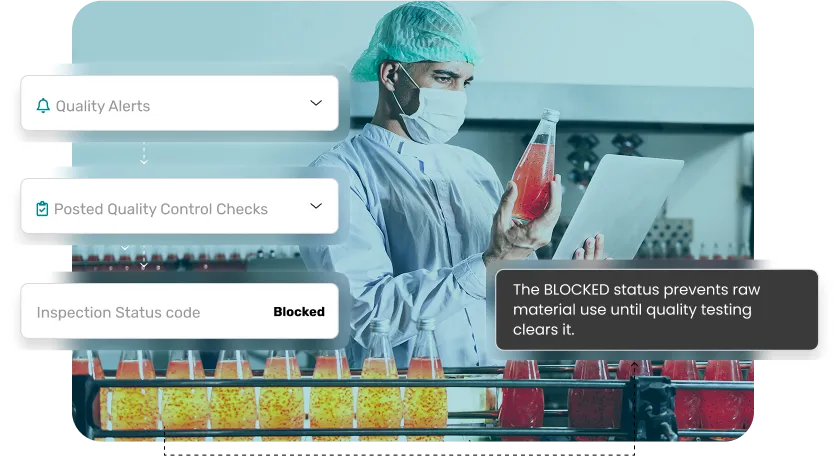

Enforce HACCP, validate nutrition and allergen data, and prepare instant recall actions if issues arise.

Handle retail EDI orders, deductions, and co-pack agreements without losing control of margins or compliance.

Plan trade spend, match retailer deductions, and measure lift from food promotions with accurate ROI insights.

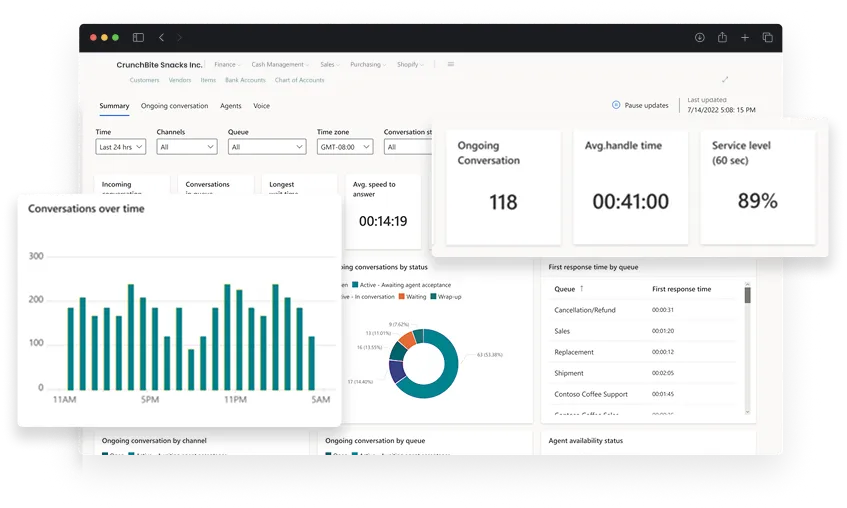

Build loyalty with self-service portals giving buyers visibility into products, inventory, and real-time shipments.

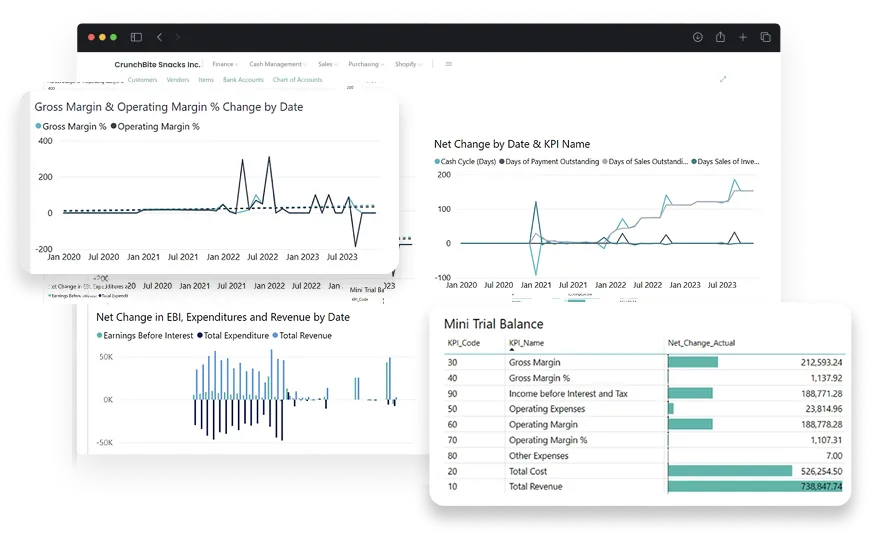

Track trade spend, SKU profitability, and promotion costs while keeping audits and retailer settlements accurate.

Turn shelf-life losses, deduction trends, and promotion performance into insights that guide faster food processing decisions.

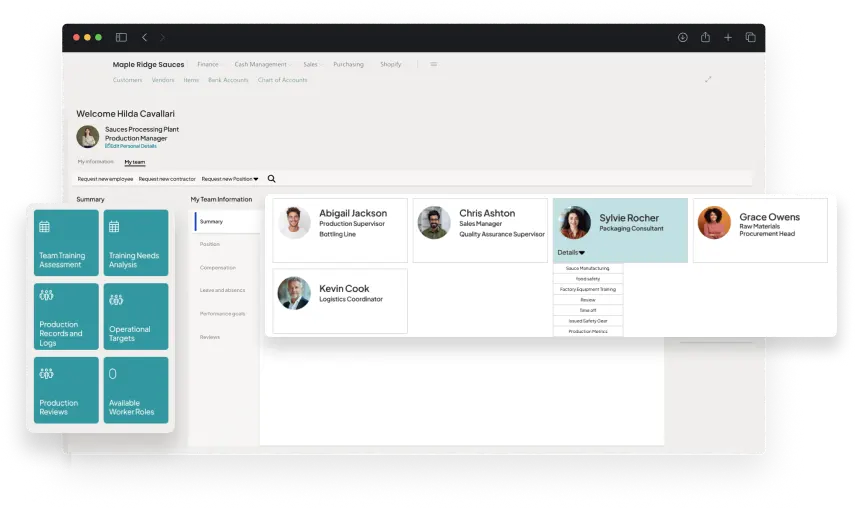

Empower food production teams with compliance-ready scheduling, payroll, and workforce safety management tools.

Seize retail, export, and consumer opportunities by unifying operations with a purpose-built packaged food ERP.

Keep products fresh, compliant, and always retail-ready, even with short shelf lives and fast-moving demand.

Run multiple client brands seamlessly by managing recipes, packaging formats, and contract terms in one connected ERP system.

Scale online and subscription sales confidently with automated recurring orders, synchronized inventory, and real-time fulfillment visibility.

Expand globally with ease by automating export documentation, ensuring compliance, and securing traceability across international markets.

Stay profitable across retail, wholesale, and eCommerce with unified pricing, synchronized stock, and promotion-ready forecasting.

Build stronger consumer loyalty by aligning every packaged product with rigorous food safety, traceability, and FSMA compliance protocols.

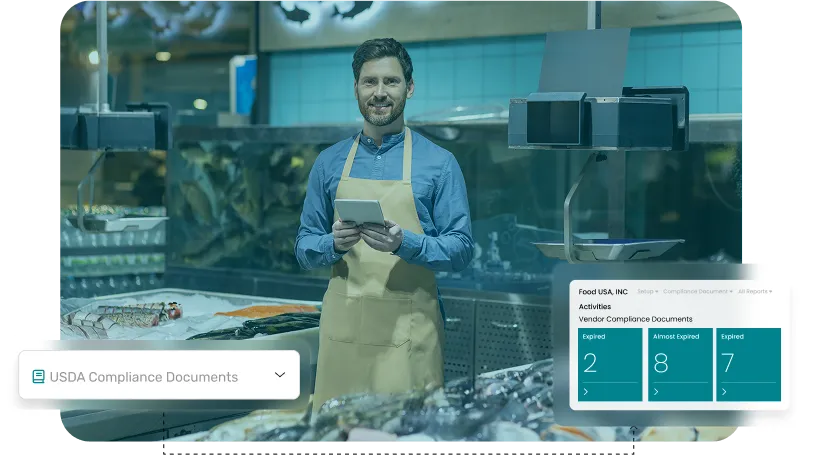

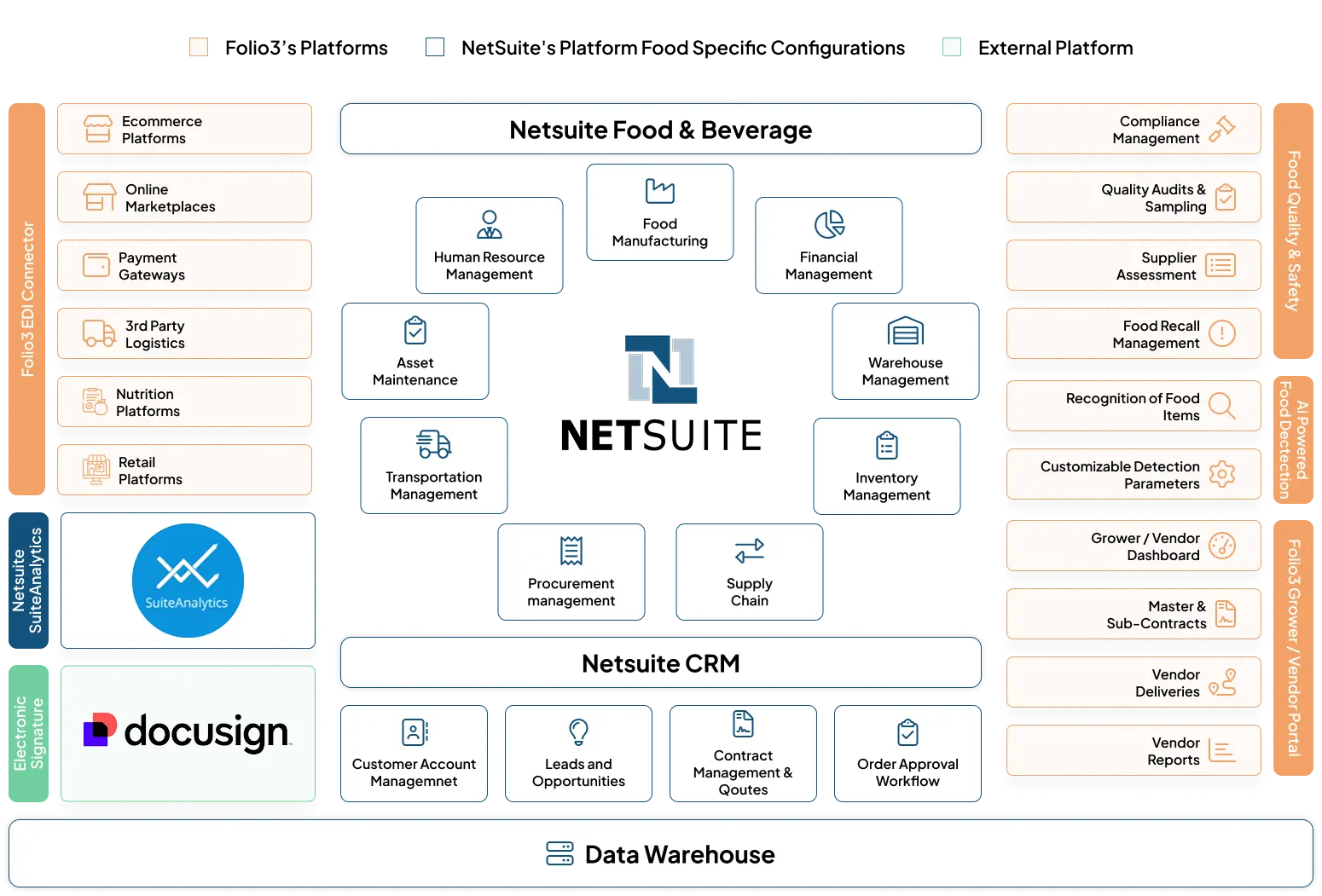

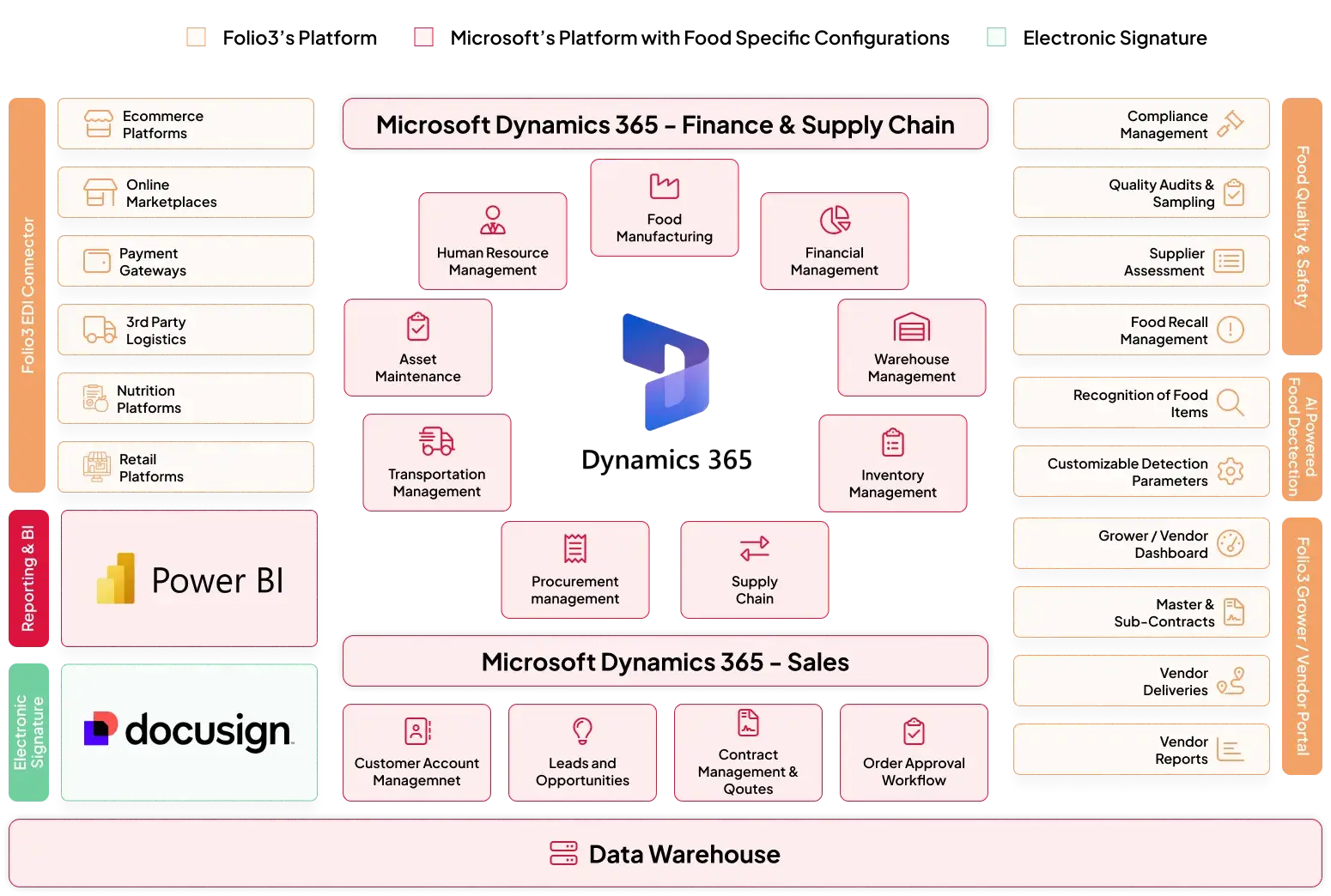

Maintain FDA, USDA, and GFSI compliance by centralizing audits, certifications, and regulatory documentation across packaged food operations and distribution channels.

Enforce HACCP checks, in-line inspections, allergen validations, and lab test integrations to ensure every SKU meets strict food-grade quality benchmarks.

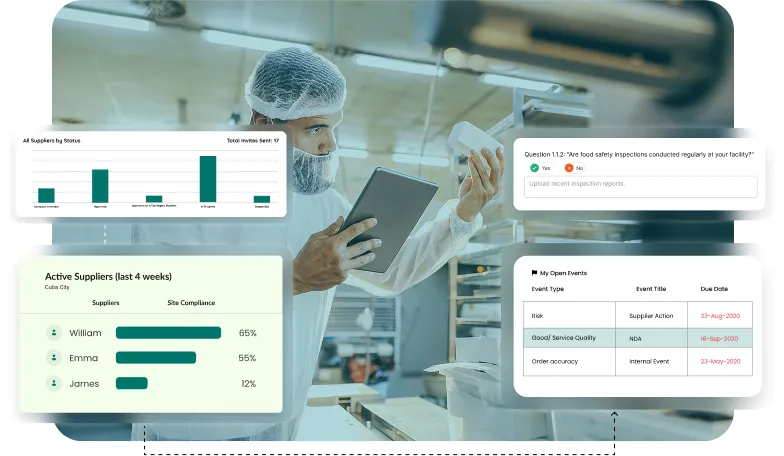

Qualify vendors with audit trails, manage certificates of analysis, and score ingredient suppliers on safety, consistency, and compliance readiness.

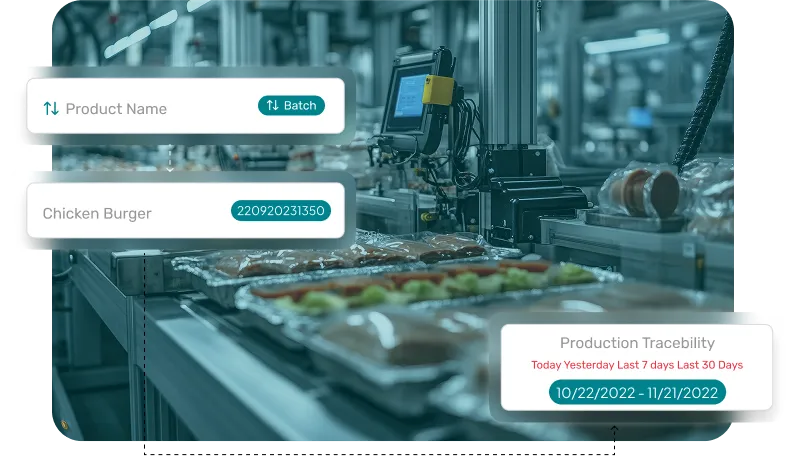

Enable end-to-end lot traceability with GS1 standards, batch genealogy, and forward-backward tracking from raw material sourcing to retailer shelf.

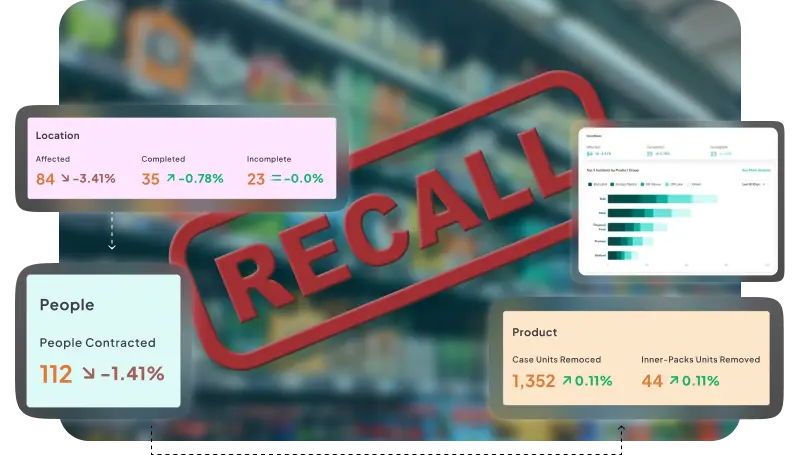

Execute rapid, targeted recalls by isolating affected SKUs instantly, generating compliance reports, and notifying distributors, retailers, and regulators automatically.

Switch from fragmented apps to a single consumer goods ERP software that integrates everything from production to retail. Work smarter every day.

Backed by 20 years in food and beverage, we deliver ERP consumer goods implementation without disruption.

We analyze your operations, from recipe management to retail compliance, to define consumer goods ERP software requirements aligned with food and beverage industry challenges.

Together, we build a roadmap that covers SKU complexity, shelf-life control, and promotion-driven forecasting across food manufacturing and distribution.

Our team configures and customizes modules for production, compliance, and trade promotions to reflect your business’s unique category needs.

Rigorous testing ensures traceability, FEFO inventory, labeling compliance, and financial accuracy before Consumer packaged goods ERP goes live in your operations.

We connect ERP with supply chain partners, retailer systems, and eCommerce channels for unified visibility and smoother category-wide execution.

SKU catalogs, batch records, and promotion history are cleansed and migrated securely into ERP while preserving compliance and data accuracy.

ERP is rolled out in controlled phases to minimize downtime while keeping production, warehousing, and distribution fully operational.

We equip teams with hands-on training and provide ongoing support to ensure adoption across production, finance, and compliance functions.

From milk intake to packaged cheese, get full control over freshness, traceability, and compliance.

Whether it’s bottled water or seasonal juices, simplify bottling, distribution, and retailer-ready promotions.

Protect cold chain integrity, cut expiry losses, and keep frozen stock moving to shelves on time.

Stay ahead of short shelf lives with smarter production runs and on-point labeling every day.

Manage endless flavors, pack formats, and seasonal launches while tracking every trade dollar spent.

Scale confidently with growing SKUs, faster line changeovers, and accurate forecasts during demand surges.

Guarantee USDA/FDA compliance, manage variable weights, and trace every cut from plant to store.

Keep recipes consistent, packaging flexible, and distribution smooth, whether for ketchup, mayo, or dressings.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

It’s a unified system that links trade spend with demand forecasts, adjusts production runs to promotion lift, and enforces retailer requirements like EDI, routing guides, and labeling. For food brands, this means fewer penalties, less waste, and smoother launches.

Most mid-sized food companies go live in 4–6 months, while larger multi-plant rollouts can stretch to 9–12 months. The timeline depends on scope, integrations, and whether you phase modules like TPM or shelf-life control first.

Look for built-in promotion planning, deduction matching, and post-event ROI reporting. In high-volume food categories like snacks, dairy, and beverages, the ERP should also support bill-back validation and retailer scan-data ingestion. Folio3 FoodTech ERP delivers these capabilities, helping CPG food companies protect margins where promotions and deductions hit hardest.

Modern ERP platforms integrate POS sell-through data, promotional calendars, and historical demand into forecasting engines. This enables channel-level forecast consumption, collaborative S&OP, and scenario planning. Food companies gain accurate demand signals to balance production, inventory, and distribution in volatile markets.

Core Dynamics 365 modules handle manufacturing, financials, and distribution, while industry accelerators extend into TPM, EDI, and lot traceability. Food & beverage brands typically deploy Trade Allowance Management for promotions, Advanced Warehouse/Batch Management for FEFO lot control, and integrated EDI frameworks for retailer compliance.

It should support multi-warehouse visibility, catchweight/variable-weight handling, GS1 pallet labeling, and automated routing guide compliance. For 3PL partners, portals, ASN generation, and direct EDI links are essential to ensure retail orders are fulfilled without chargebacks or delays.

Traceability runs through lot genealogy, FEFO allocations, and allergen tagging at the batch level. A recall can then instantly isolate affected lots across internal plants and outsourced 3PLs, with regulatory audit trails generated automatically.

ERP must integrate native APIs for D2C platforms like Shopify or BigCommerce, plus marketplace feeds from Amazon/Walmart, alongside traditional EDI flows. This creates a single inventory ledger where every channel consumes the same stock pool in real time. Folio3 FoodTech specializes in building these unified integrations for food CPG companies.

The ERP should use hierarchical BOMs for cases, inners, and pallets, enforce GS1-128/UCC barcoding at each level, and support catchweight items like meat or cheese with variable-weight SKU rules.

Formulation modules push approved recipes and nutritional/allergen profiles into ERP BOMs. From there, packaging specs and label artwork (nutrition panels, allergen statements, certifications) are version-controlled, ensuring every launch is compliant before manufacturing begins.