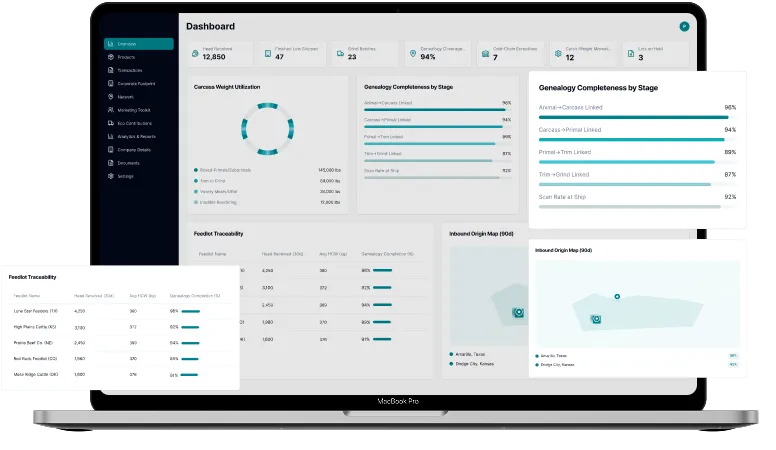

Trace carcasses and products with precision across every stage. Meat traceability system unifies genealogy, weight records, and cold chain monitoring, giving processors instant control in audits and recalls.

Put every lot, carcass, and shipment under control. With traceability built into daily operations, your plant runs safer, faster, and more accountable.

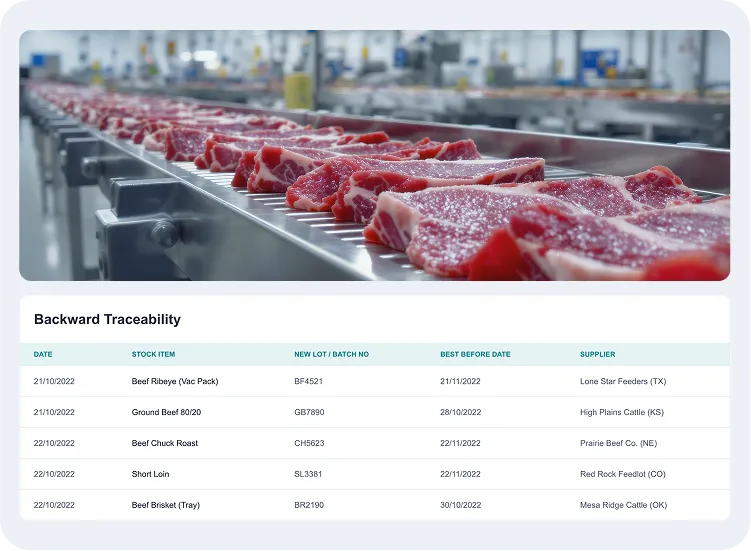

Trace ribeye, trim, or ground beef lots back to the carcass and supplier within seconds.

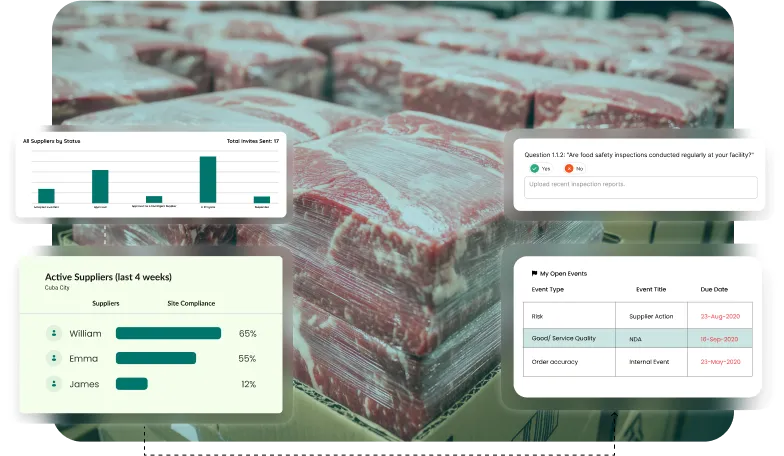

Link carcass lots, COAs, and yields directly to supplying feedlots, ensuring supplier accountability across operations.

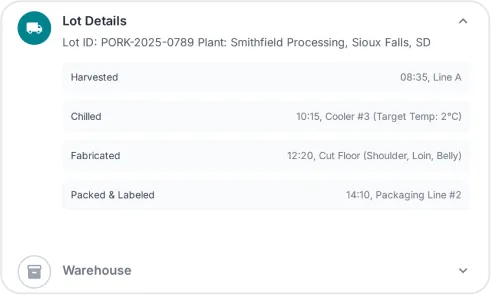

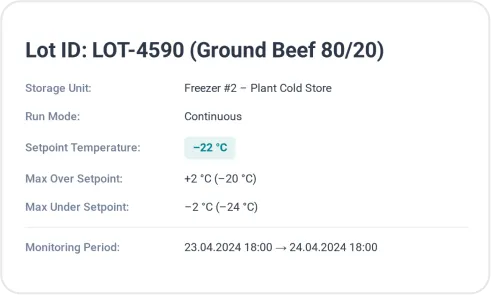

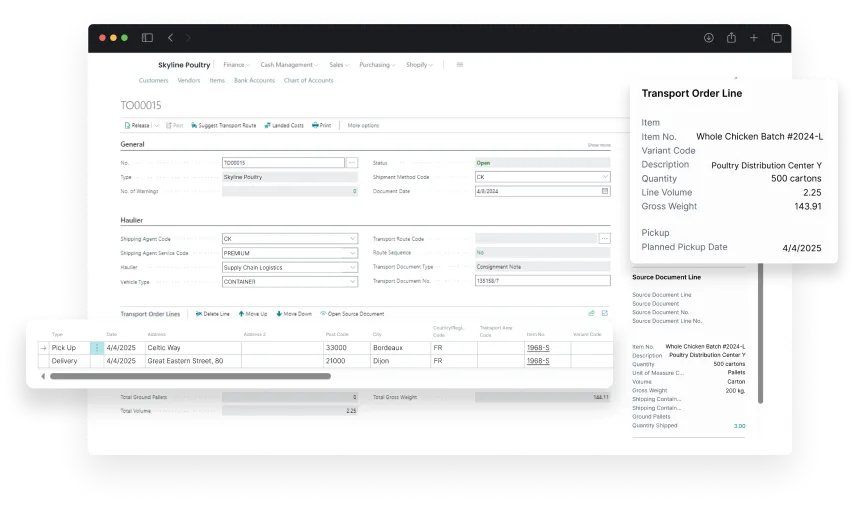

Monitor carcass chillers and reefer routes continuously, with deviations automatically linked to specific product lots.

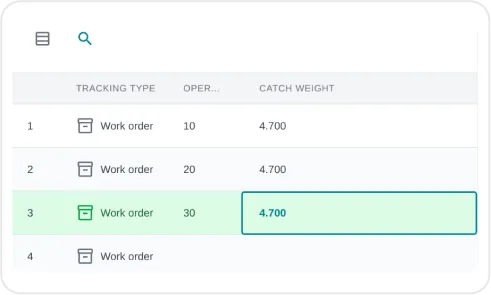

Capture exact loin, rib, and grind weights; auto-reconcile inventory, pricing, and GS1 label compliance rules.

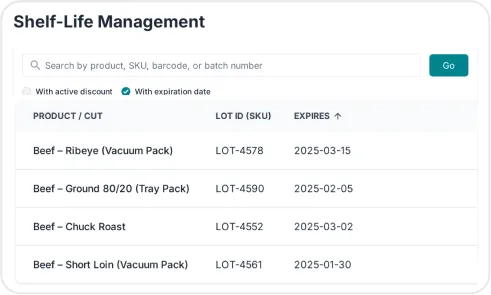

Manage cooler and freezer lots by production date and shelf-life rules, enforce FEFO picking, and flag ageing product before it risks shrink, compliance failure, or recall exposure.

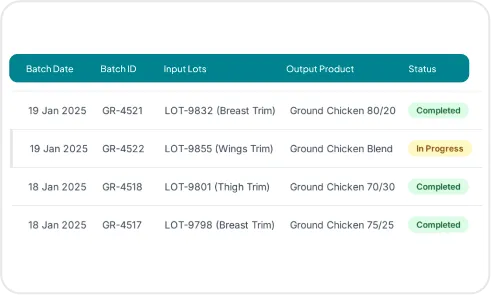

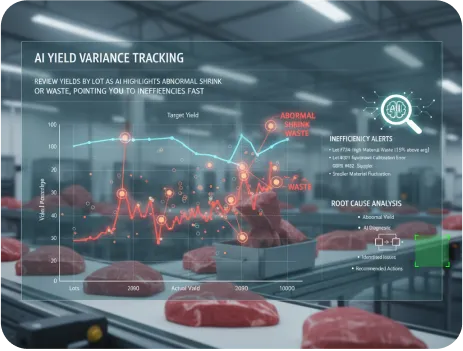

Compare carcass input to primal and trim outputs, uncover shrink, and monitor supplier-specific yield performance.

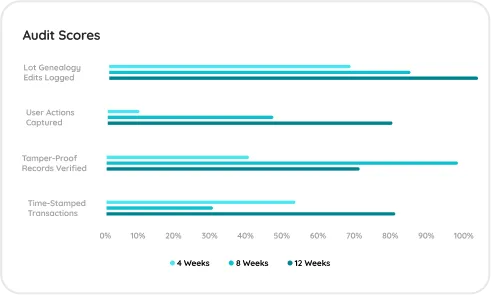

Keep your plant audit-ready every day with real-time meat traceability software that unites safety, efficiency, and accountability.

Ensure safer meat operations by combining traceability with our wider food safety suite built for plant protection.

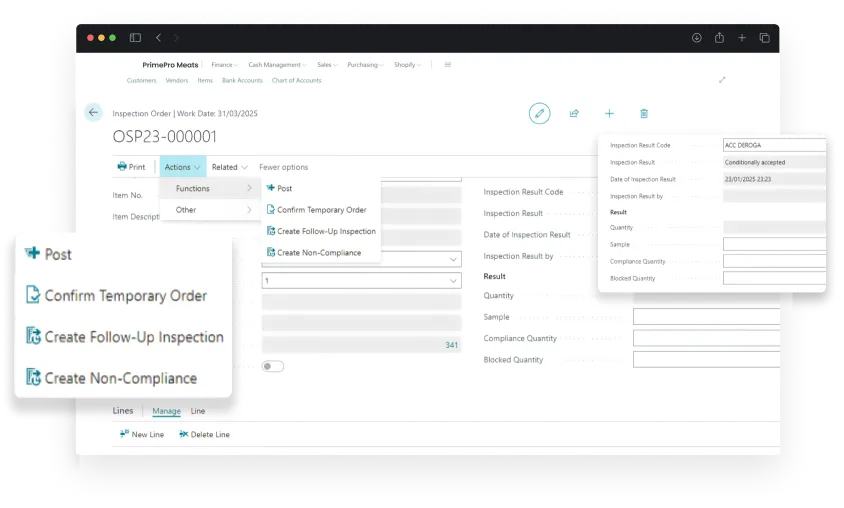

Maintain HACCP plans, FSIS documentation, and daily SOP checks in one system, keeping your plant audit-ready at all times.

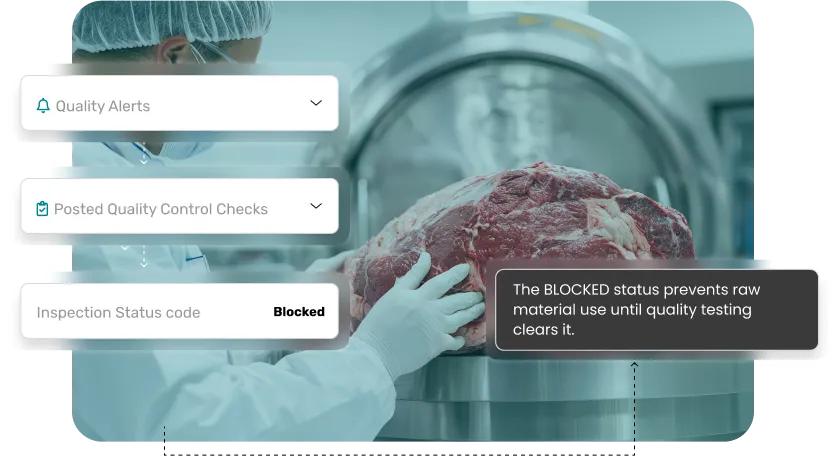

Track carcass grading, microbial testing, and packaging accuracy in real time to protect product integrity before it leaves the floor.

Capture COAs, monitor lot yields, and benchmark supplier performance, so sourcing decisions are backed by traceable, data-driven accountability.

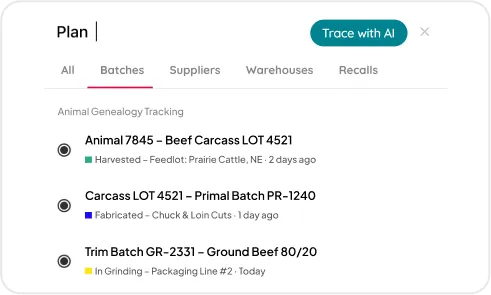

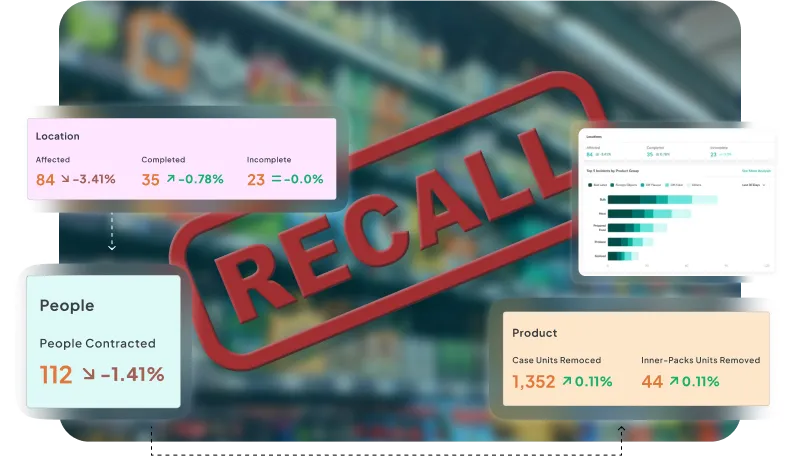

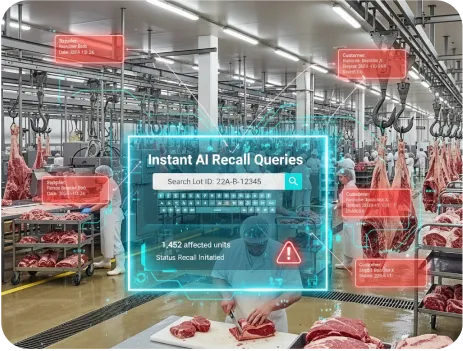

Execute forward and backward lot tracing within seconds, isolate only impacted batches, and trigger FSIS-compliant recall actions plant-wide.

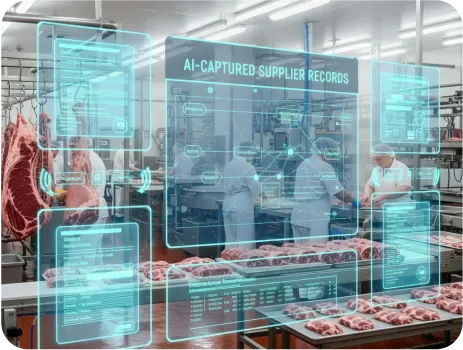

Scan supplier certificates and delivery notes to let AI capture details and link them to incoming lots.

Use AI to automatically identify and tag each carcass, keeping genealogy intact through fabrication and packaging.

Run recall queries instantly with AI search to trace affected lots back to suppliers or forward to customers.

Track storage and transport conditions while AI flags deviations early and links alerts to specific product lots.

Review yields by lot as AI highlights abnormal shrink or waste, pointing you to inefficiencies fast.

Rely on AI to spot unusual patterns across lots or suppliers and act before risks escalate.

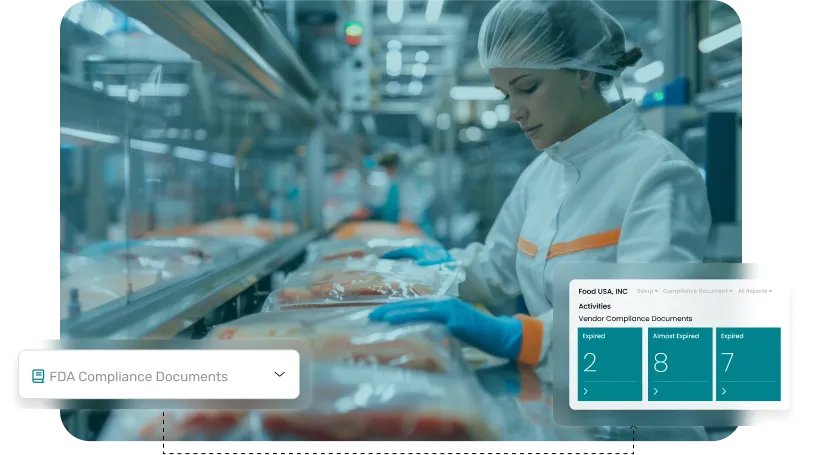

AI automation is changing the way meat plants operate. From carcass grading to packaging, AI reduces bottlenecks and improves consistency, while computer vision ensures staff compliance with safety and hygiene standards. Integrated with digital traceability, every product movement is captured for accuracy and accountability.

The real question is: will your plant lead the change or follow it?

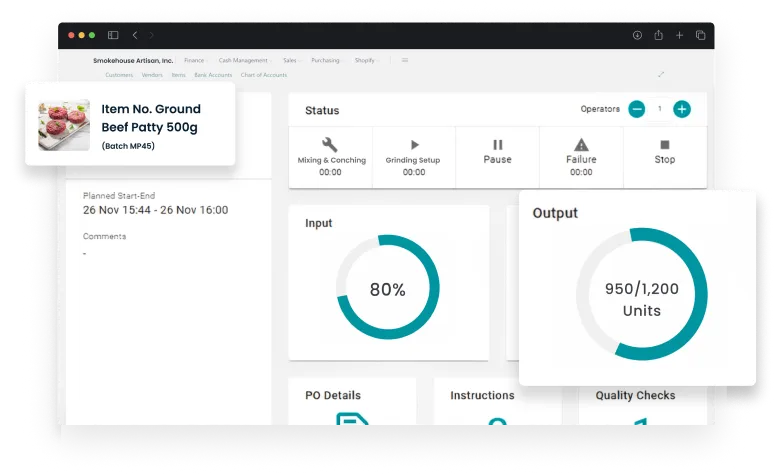

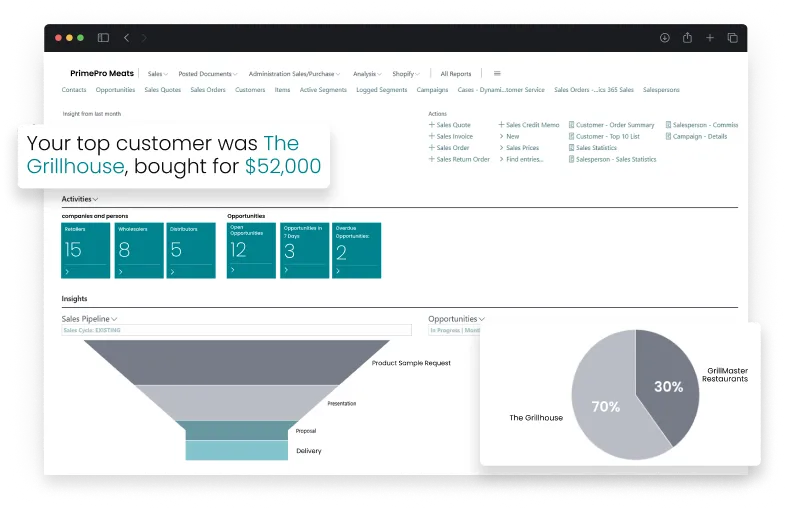

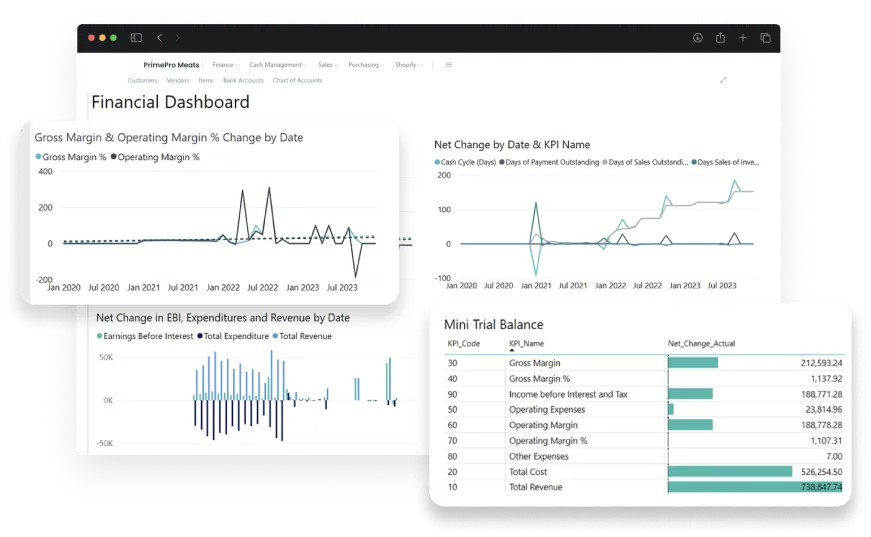

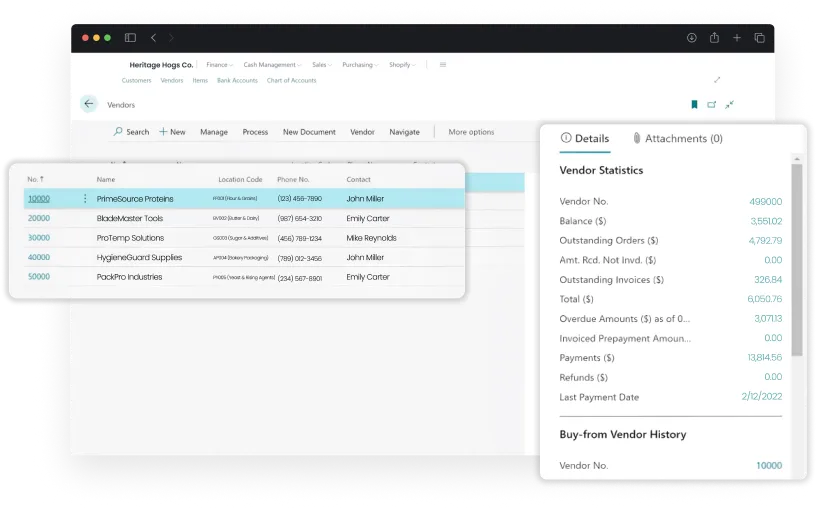

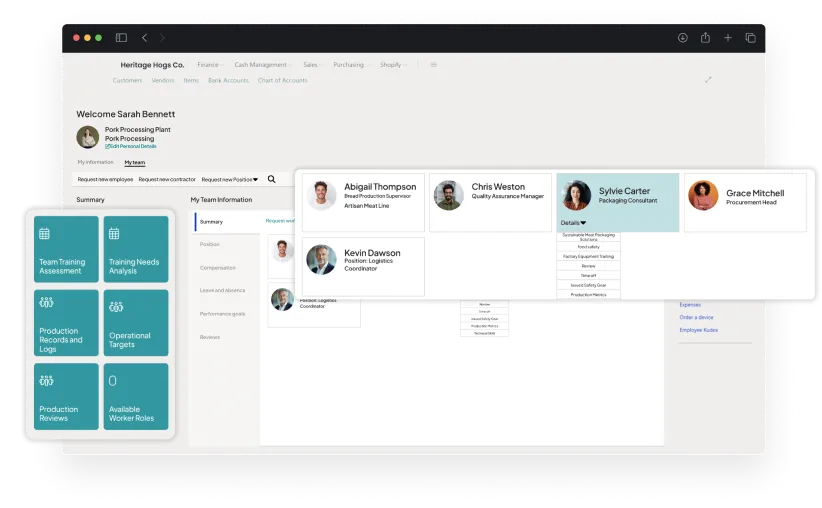

Expand from meat traceability management into an end-to-end ERP for total visibility and control across production, inventory, and financials in your meat processing operation.

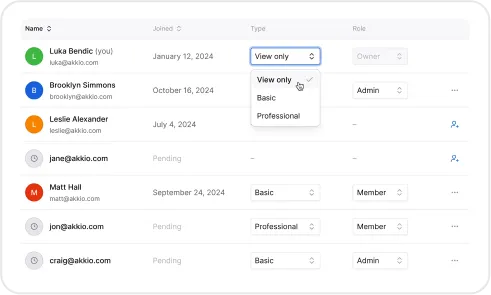

Connect meat traceability software across your business to replace fragmented data with one clear, reliable source of truth.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Meat traceability solution creates a digital record of every step in production. It starts with carcass identification at slaughter, follows each lot through fabrication and packaging, and links cold storage data before shipment. This continuous chain of records gives processors complete visibility, making audits, recalls, and daily management far more reliable.

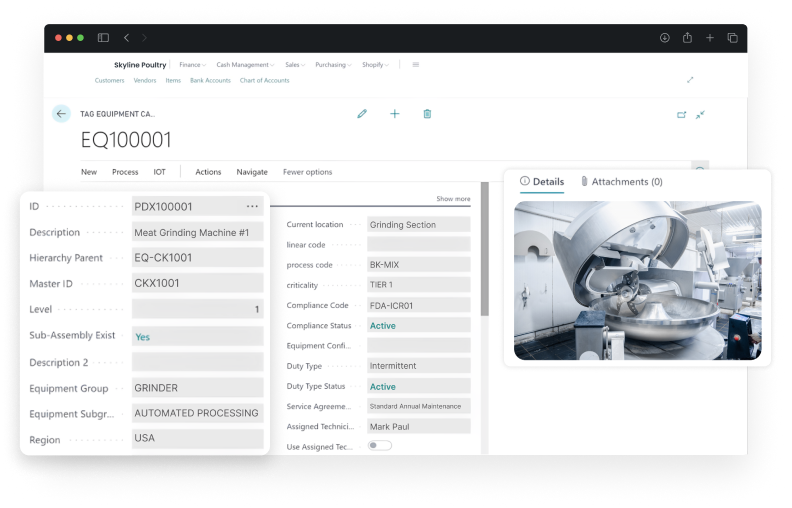

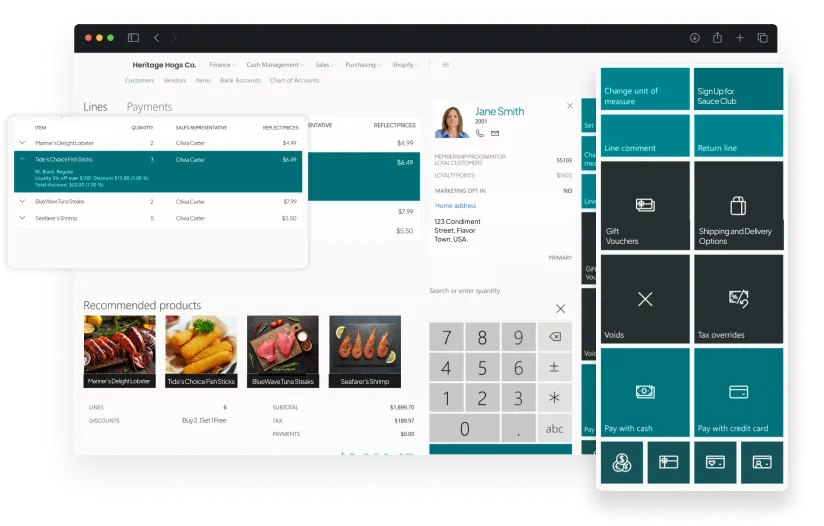

Folio3 FoodTech’s system connects with the tools plants use, scales, scanners, and line equipment. Each carcass tag or lot ID is automatically recorded as product moves through cutting, grinding, packaging, and storage. Because the data is linked in one system, processors can trace a finished box of product back to its original source in seconds.

Regulators require processors to maintain accurate records that show where a product came from and where it went. That means keeping lot IDs, production dates, packaging details, and cold chain information tied together in one system. USDA and FDA rules also emphasize being able to recall product quickly, keep HACCP documentation updated, and prove that labels and claims match the product shipped.

The software checks that weights, labels, and packaging match the right lot before the product leaves the floor. If there’s a mismatch, it flags it immediately so corrections can be made on the spot. It also stores audit trails and HACCP records in one place, helping plants avoid penalties and handle recall situations with confidence.

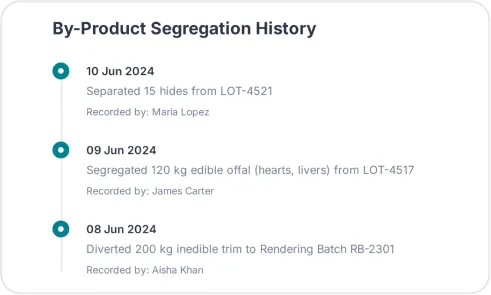

Traceability doesn’t stop with boxed products. It also tracks what happens to trim, offal, hides, and other by-products. By recording where these materials go and how they’re used, processors reduce waste, capture more value, and stay compliant with reporting requirements. This makes the entire operation more efficient and sustainable.

A meat traceability solution creates a shared record that follows each lot from farm through processing, distribution, and retail. By capturing data at every handoff, carcass tags, packaging IDs, transport scans, and delivery confirmations, all parties can view the same information in real time. This makes the meat traceability system in supply chain faster, more transparent, and far easier to manage during recalls or audits.

Digital traceability proves where meat came from and how it was handled at each step. Retailers gain confidence because they can verify supplier records, shelf-life status, and safety compliance. Consumers trust brands more when QR codes, labels, or certifications are backed by real traceability data, showing that products are safe, authentic, and responsibly sourced.

Folio3 FoodTech’s meat traceability solutions are built to integrate seamlessly with existing plant and business systems. That includes ERP platforms for finance and planning, WMS for warehouse movements, MES for production data, and automated labeling systems for catch-weights and compliance. These integrations reduce duplicate entry, keep records consistent, and provide one connected view of the entire plant.

ROI is measured in both risk reduction and operational gains. Faster recalls lower financial and reputational losses, while precise lot tracking reduces shrinkage by stopping expired or misrouted product. Yield recovery comes from better monitoring of trim, by-products, and pack weights. Together, these improvements quickly offset software investment and create measurable cost savings year after year.