Get a complete sauces ERP solution to manage your entire supply chain, from sourcing the freshest ingredients to timely distribution, and gain precise control over viscosity, texture, and shelf-life in every batch of sauces.

Whether you're producing specialty dressings or premium sauces, use an ERP system to manage every step of production and eliminate delays in the supply chain.

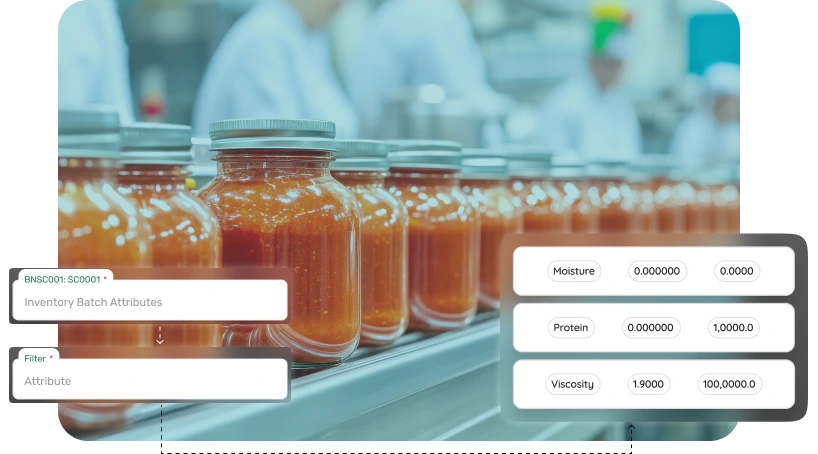

Without precise recipe management, inconsistencies in texture, flavor, and viscosity can occur, leading to batch variations that affect product quality.

A shelf-life of around 30 days in sauces and dressings, especially in products with high moisture content or fresh ingredients, leads to product wastage if not handled effectively.

Handling allergen risks in sauces and dressings is complex due to various ingredients, including common allergens like soy, eggs, and dairy.

Delays in procuring specialty ingredients like high-quality vinegar, exotic spices, or emulsifiers can disrupt production timelines, affecting consistency and quality.

Managing bulk and consumer-sized production runs in sauces requires different packaging, such as drums for bulk and bottles for retail, impacting labeling and consistency.

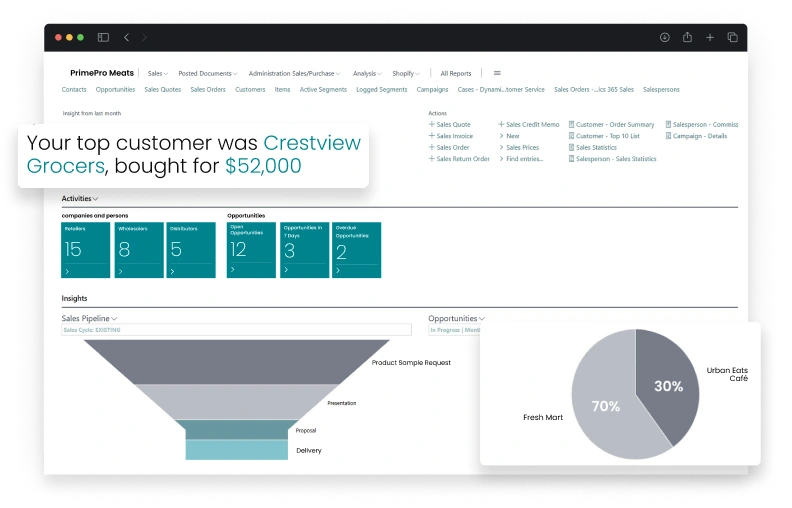

Price fluctuations, such as changes in the cost of tomatoes, oils, and specialty spices, directly impact profit margins in sauce and dressing production.

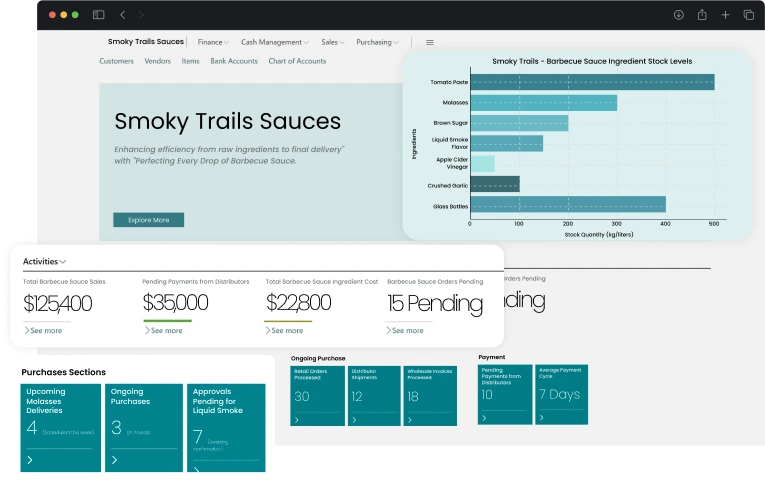

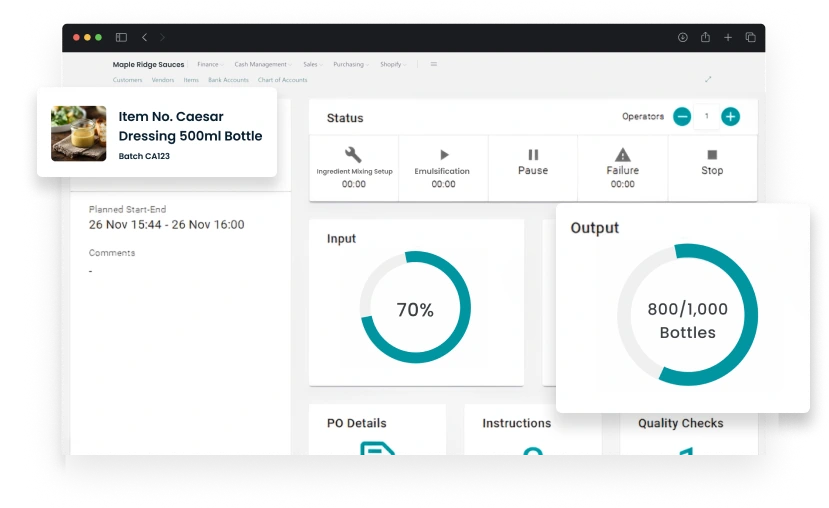

Control every step of sauce and dressing production, from sourcing ingredients to blending in kettles and cooling. Maintain consistent quality and optimize moisture yield, storage, and efficiency in real time.

From ingredient sourcing to final delivery, our sauces and dressings ERP helps manufacturers, distributors, and retailers optimize operations and enhance efficiency at every step.

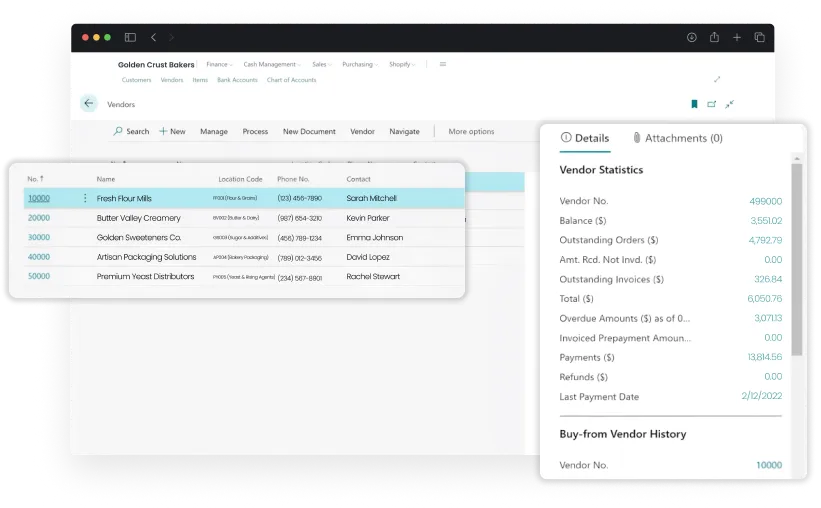

Ensure consistent delivery of fresh, high-quality ingredients like vinegar, oils, and spices. ERP tracks inventory in real-time and simplifies procurement based on production demands, maintaining just-in-time supply.

Manage recipe formulations and kettle blending for products like creamy dressings and tangy sauces. ERP optimizes batch tracking, ensuring consistency in every production phase while maintaining high product quality.

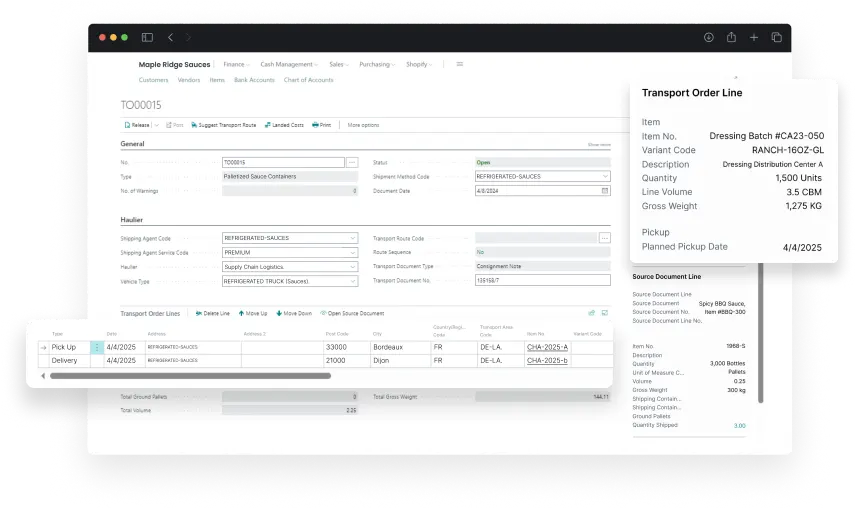

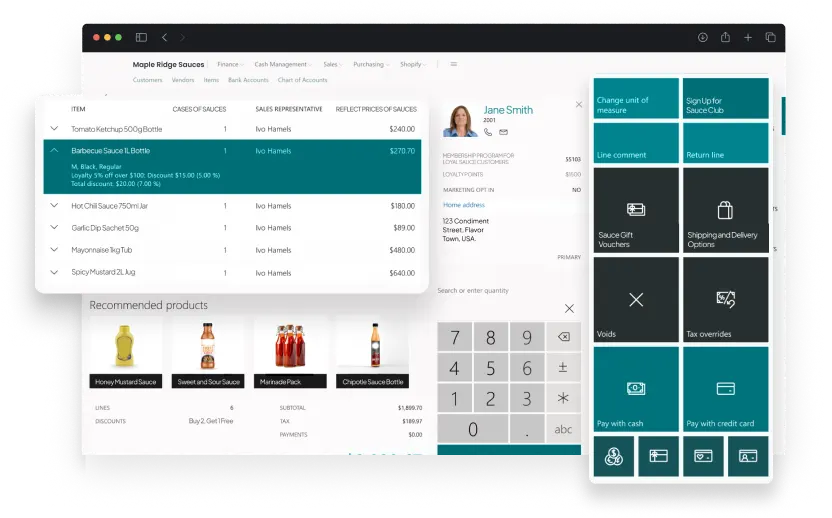

Manage the logistics and delivery of sauces, dressings, and condiments efficiently. ERP ensures accurate order fulfillment, tracks distribution timelines, and simplifies invoicing, enabling faster, more reliable service to retailers and food service.

Gain real-time visibility into product availability for sauces like ketchup, mayonnaise, or dressings. With ERP, optimize stock levels, manage multiple SKUs (e.g., bottles, jars), and keep the order fulfillment process running smoothly.

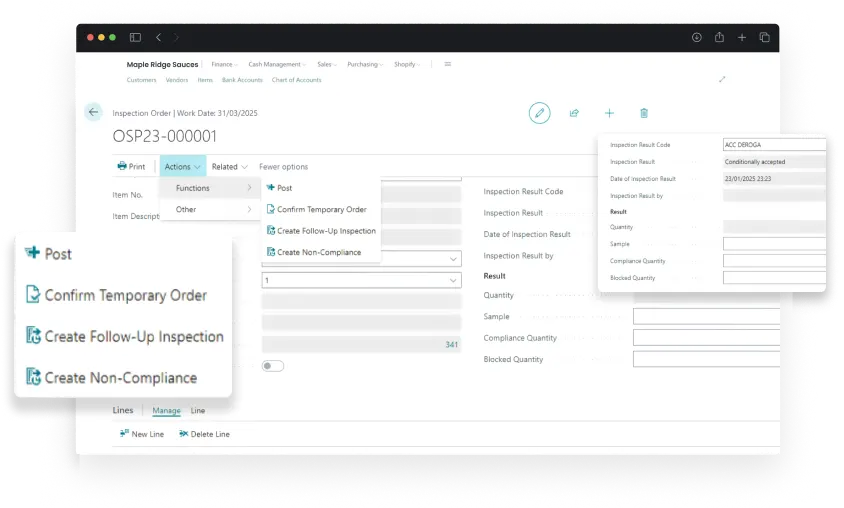

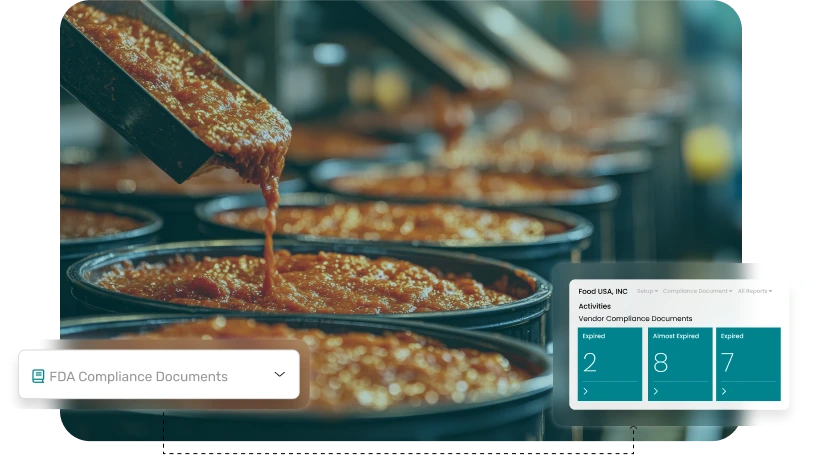

Meet FDA and other food safety standards to prevent contamination across production stages like emulsification, blending, and cooling. Maintain the integrity of your sauces & dressings while protecting consumer trust.

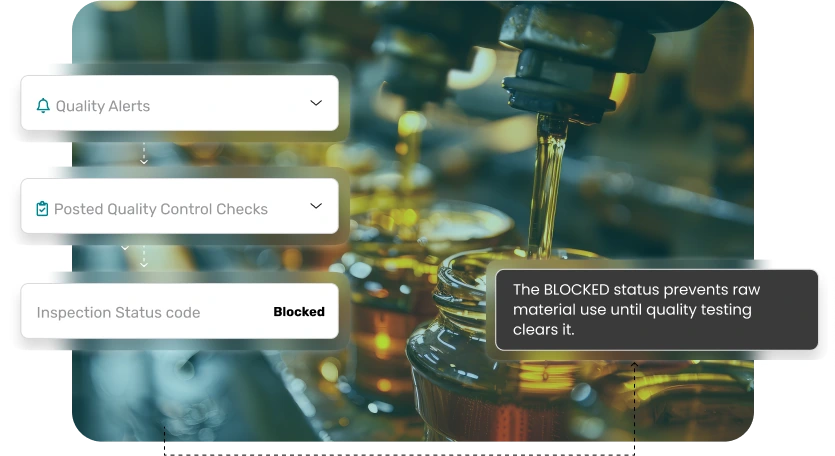

Ensure compliance with FDA standards by monitoring allergen cross-contamination, pH levels in vinaigrettes, and acidity in tomato-based sauces.

Maintain consistency by precisely controlling viscosity in cream-based dressings, moisture in high-viscosity pastes, and cooling timelines during kettle blending.

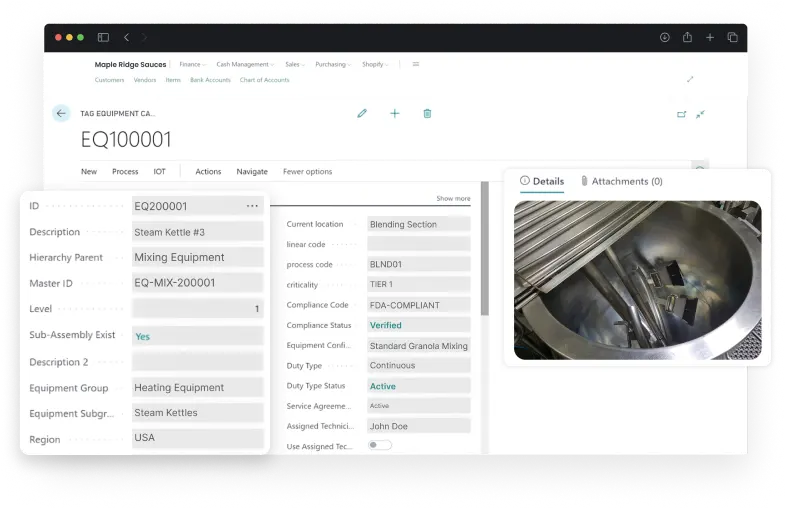

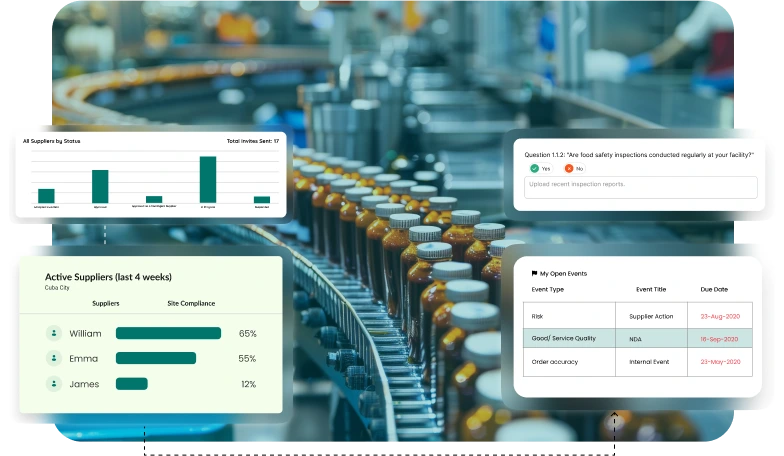

Vet and manage ingredient suppliers to maintain the integrity of emulsifiers, stabilizers, and other critical raw materials.

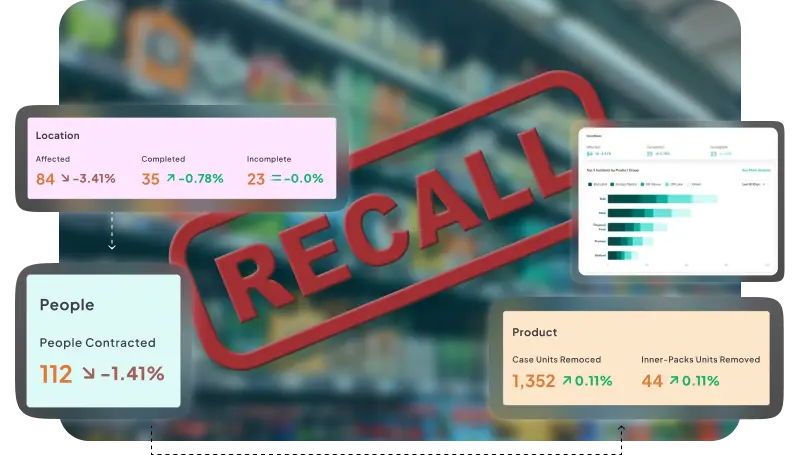

Quickly trace and isolate defective batches of sauces or dressings with lot-based recall tracking systems.

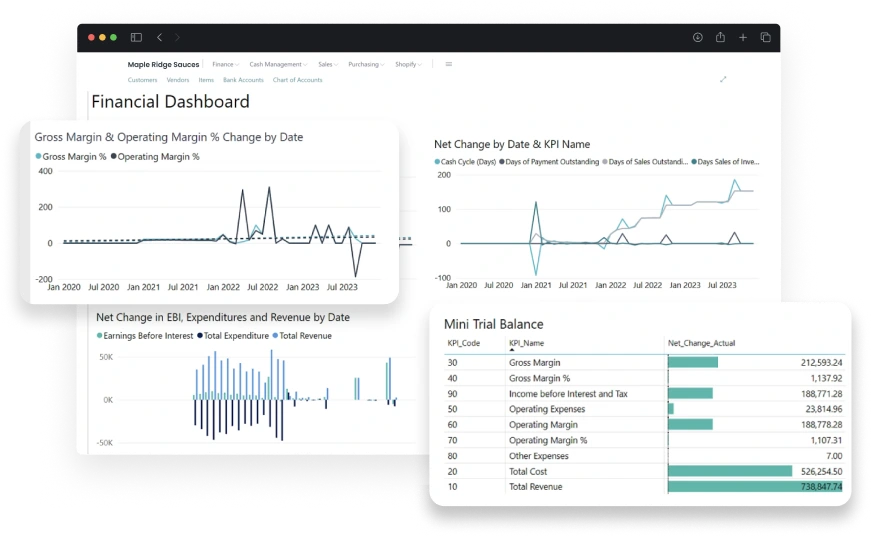

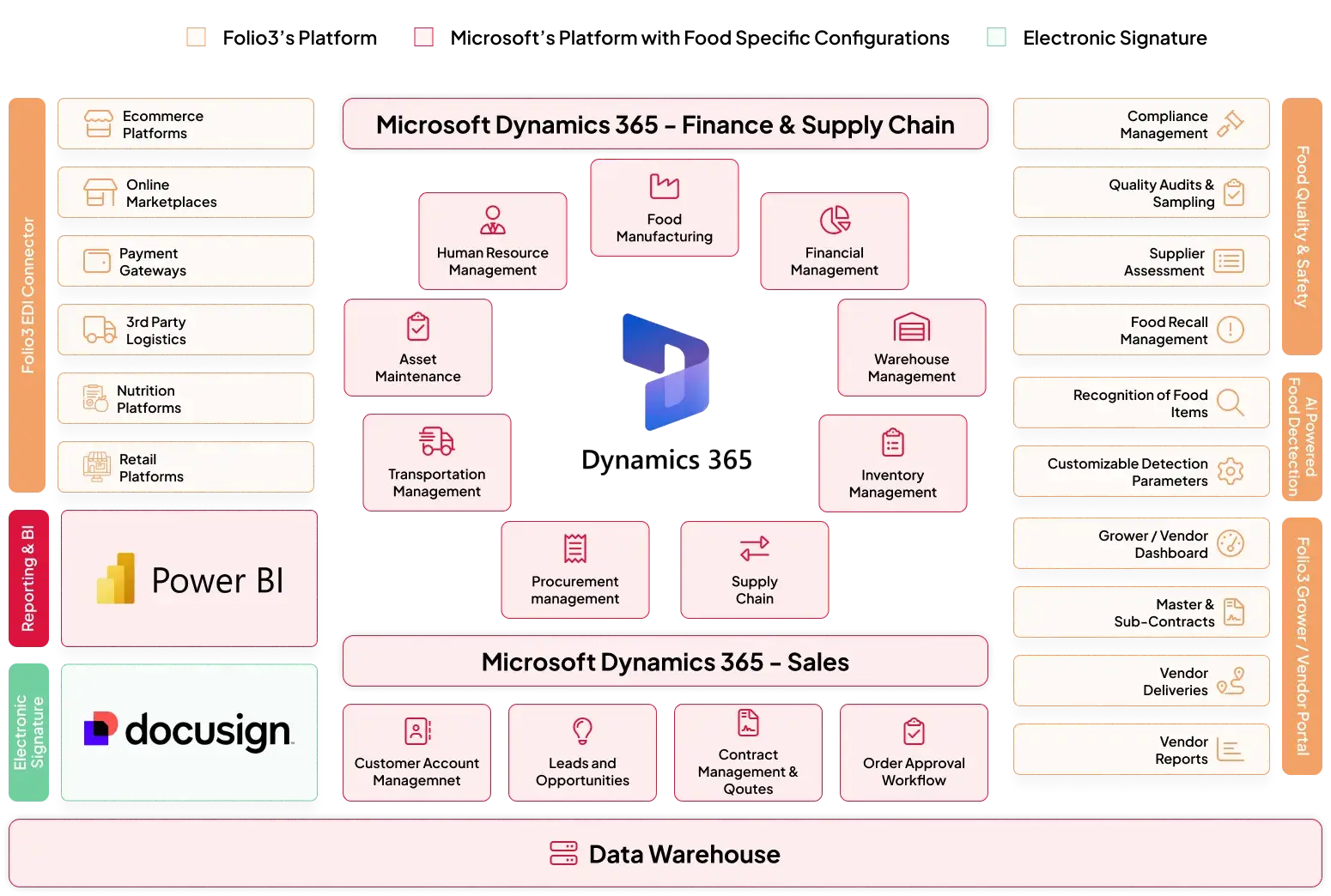

Replace scattered tools with a single ERP system to manage data from kettle blending, recipe tracking, production, sales, and finance—all at your fingertips.

Rely on our industry expertise to implement a fast, effective ERP system that aligns perfectly with your sauce and dressing production needs.

We begin by understanding the unique challenges in your sauce and dressing production, such as flavor consistency, batch tracking, and ingredient sourcing, to design sauces and dressings ERP software that meets your specific needs.

We create a detailed project plan to address key aspects of sauce production, such as recipe management, quality consistency, and delivery schedules, ensuring minimal disruption.

We customize the ERP system to manage sauce-specific processes like ingredient blending, batch production, and packaging, aligning it with your plant's production goals.

We thoroughly test ERP modules to ensure they handle essential tasks like recipe accuracy, temperature control, and traceability, ensuring quality across all production runs.

We integrate the ERP system with your existing tools, such as inventory management, supplier tracking, and order fulfillment, to streamline all aspects of sauce production.

We securely transfer critical sauce production data, including recipes, batch information, ingredient suppliers, and sales history, to ensure a smooth transition to the new ERP system.

We deploy the ERP system in your sauce production environment, optimizing it for batch tracking, inventory management, and order fulfillment to ensure a smooth and efficient transition.

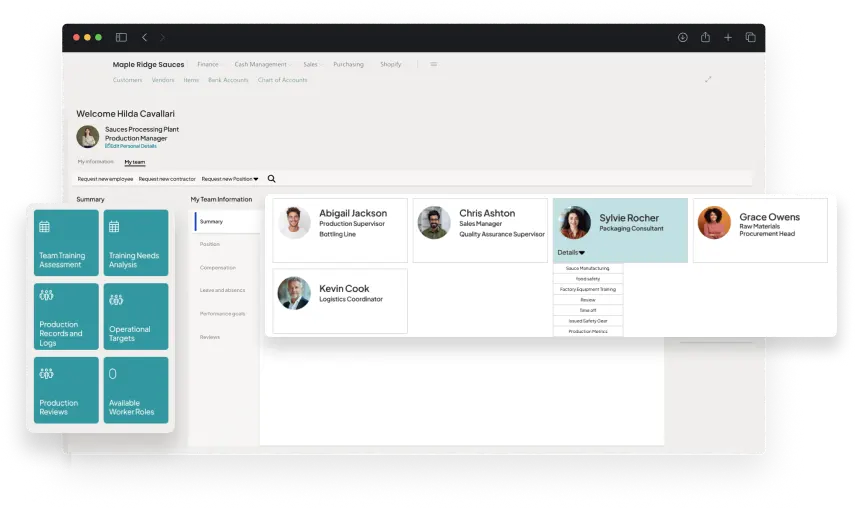

We offer extensive training and ongoing support to ensure your team fully utilizes ERP for sauces and dressings, from managing production schedules to handling ingredient sourcing and compliance reporting.

Track milk from farm to shelf, ensuring freshness, quality, and safety while optimizing production and extending shelf life.

Keep your beverage production in check with consistent quality, ingredient tracking, and efficient batch management from start to finish.

Track storage conditions, manage production based on demand, and reduce waste, ensuring your frozen foods stay fresh longer.

Simplify your bakery operations with tools for inventory, recipe management, and quality control to stay ahead of trends.

Manage ingredient inventory, allergen safety, and production cycles to deliver sweet products with consistency and safety.

Handle large-scale snack production with real-time inventory, ingredient sourcing, and quality control.

Track meat quality and processing conditions, meeting safety standards while maintaining efficiency and product consistency.

Maintain batch control, track ingredient sourcing, and ensure consistent flavour profiles for every batch of your sauces.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Sauces and dressings manufacturers often deal with complex batch processing, quality assurance, and regulatory compliance. Sauces and dressings ERP solutions tailored for this industry can streamline operations, manage complex formulations, and ensure adherence to food safety standards.

A specialized ERP system provides bidirectional end-to-end traceability of all materials, ingredients, and finished goods, which is critical for organizations that engage in complex batch processing.

Yes, ERP solutions designed for sauces and dressings manufacturing can manage large batches of raw materials between kettles, cooling, and storage, accounting for yield and informing future purchasing and production decisions.

These ERP systems analyze yield for moisture, temperature, and quality in real time, allowing adjustments to future orders, production schedules, and recipes to optimize raw material usage and ensure timely order fulfillment.

The ERP includes features such as lot traceability, quality assurance, batch processing, yield management, bill of materials, production scheduling, work-in-progress tracking, waste management, and support for multiple units of measure to ensure compliance with food safety regulations.

The ERP software is designed to help companies operate more efficiently, comply with food safety initiatives, and scale operations by managing complex formulations, measuring for consistency, and accounting for multiple units of measure.

Yes, ERP solutions for sauces and dressings manufacturers are designed to scale your business, accommodating increased production volumes and expanding operational needs.

Comprehensive support is provided throughout the implementation process, including training, customization, and ongoing assistance to ensure the ERP system meets the specific needs of sauces and dressings manufacturers.

Yes, the ERP software for sauces manufacturers is designed to integrate seamlessly with existing production equipment and third-party applications, facilitating real-time data exchange and improved operational efficiency.

The implementation timeline can vary based on the complexity and specific business requirements, but with a structured approach, the process can be efficiently managed to minimize disruption.