Manage your seafood operations from catch to customer. Our seafood ERP software gives processors, distributors, and fisheries complete control over compliance, production, and profitability. With ERP software for seafood industry powered by AI forecasting, IoT monitoring, and blockchain traceability, you gain real-time visibility to cut waste, meet regulations, and drive sustainable growth.

Since 2004, we’ve helped 100+ food businesses across global markets simplify operations, boost compliance, and scale sustainably with our ERP solutions. With two decades of industry expertise and a dedicated focus on ERP for seafood, we empower processors, distributors, and fisheries to achieve efficiency. Our team has implemented seafood manufacturing software in plants of every size, streamlining day-to-day work so profitability is protected at every stage.

Running a seafood business means managing variable weights, perishable stock, strict regulations, and global trade complexities. Our ERP software for seafood unifies these unique challenges into one platform. From pricing and compliance to cold-chain and sustainability, it equips your facility to perform with accuracy, efficiency, and confidence.

Ensure every gram counts with automated pricing that adapts to seafood’s variable weights, grades, and seasonal fluctuations. This feature protects profitability while keeping customer contracts transparent and compliant.

Keep seafood fresh and audit-ready with IoT-enabled temperature and humidity tracking from vessel to distribution. Our seafood ERP system ensures you never lose product value to preventable spoilage.

Achieve regulatory peace of mind with traceability that spans vessels, crews, processors, and distributors. This functionality makes ERP software for the seafood industry a compliance powerhouse.

Turn filleting, trimming, and packing into measurable metrics. Our seafood ERP solution empowers processors to improve yields, reduce waste, and maximize profitability across facilities.

Stay competitive with built-in sustainability management. From eco-labels to carbon tracking, our ERP seafood solution helps seafood businesses prove responsibility and win customer loyalty.

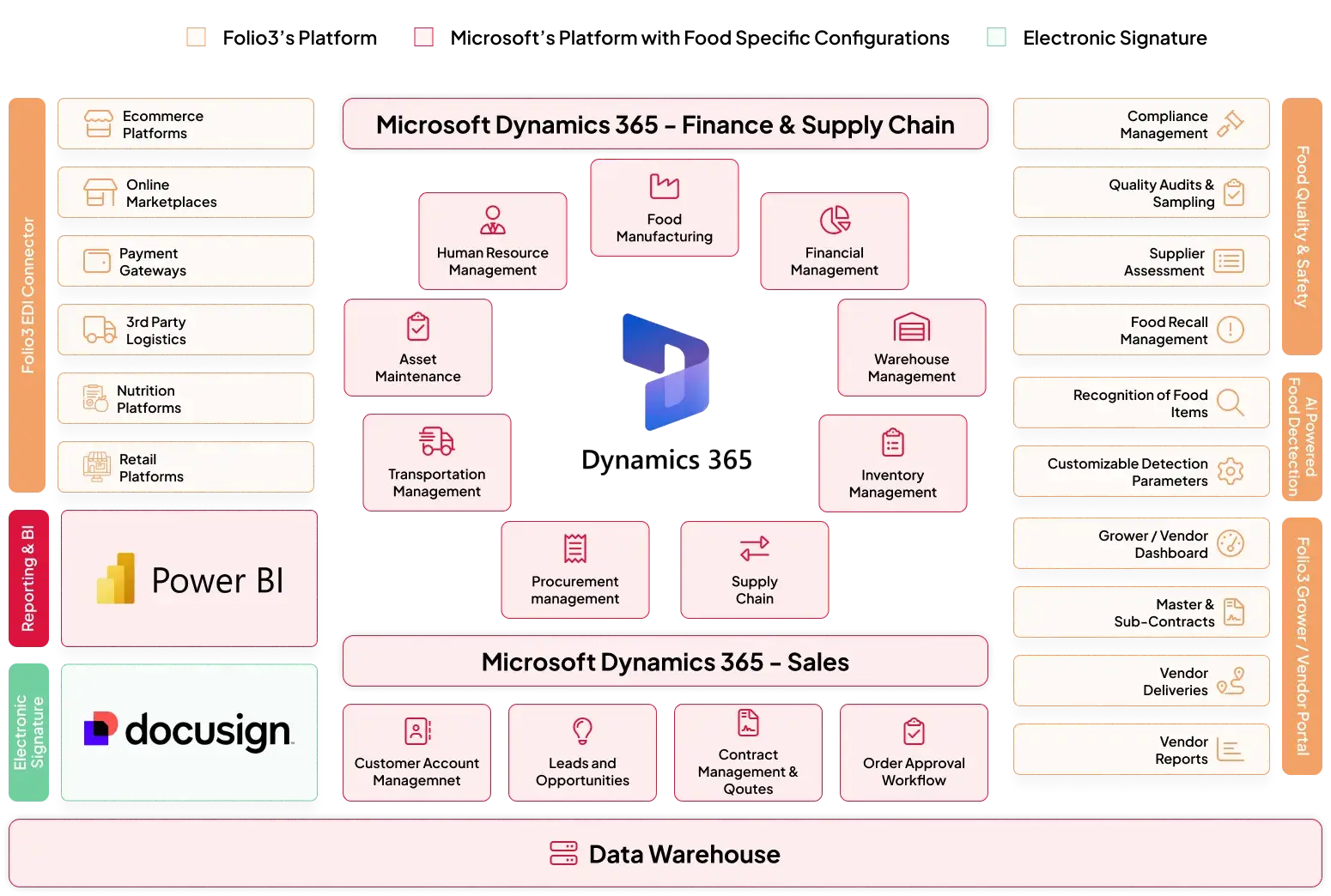

At Folio3 FoodTech, seafood ERP software is designed to transform the way you operate, not just manage the current workflow. We combine deep seafood expertise with next-gen tech to deliver measurable results: faster compliance, reduced waste, higher margins, and more intelligent decisions across your entire value chain. By revolutionizing the seafood industry through our ERP solutions, we give you multiple reasons to choose us, considering our following USPs:

AI-powered demand forecasting helps seafood companies cut wastage, balance volatile supply, and protect already thin margins.

IoT sensors track temperature, humidity, and location in real time, so you can prevent spoilage before it threatens your bottom line.

Blockchain verification proves origin, species, and sustainability credentials, building loyalty with consumers and confidence with regulators.

Native food and retail EDI means faster partner onboarding, fewer integration headaches, and smoother supply-chain transactions.

From fleets and aquaculture to processors and distributors, we cover the seafood chain end-to-end while applying learnings from other food sectors.

Partner with a single provider for ERP, CRM, mobile apps, and analytics, delivering value that goes beyond ERP to support every stage of your food business growth.

Running a seafood business requires more than just basic tools; it demands an ecosystem of specialized modules. With our expertise, we bring together processing, planning, compliance, and distribution in a single seafood ERP system designed for real-world complexity.

Digitize Every Landing Event from Vessel to Dock

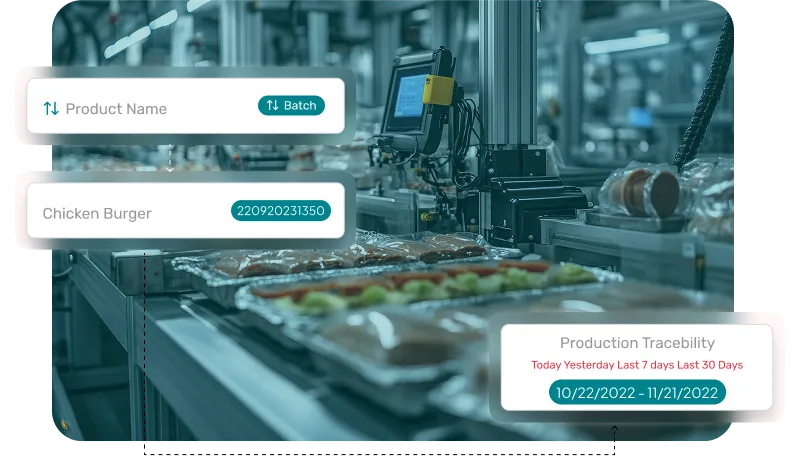

Record species, grades, trip data, and weights at landing with full integration into your ERP for seafood processing. Software for seafood processors automates settlements, tracks costs, and provides a transparent chain of custody from ocean to buyer, all within your erp for seafood processing footprint.

Align Supply with Unpredictable Demand

Balance harvest schedules, processing capacity, and market demand with intelligent planning inside our seafood ERP solutions. Anticipate shortages, cut delays, and plan production cycles that adapt to seasonal variability and fast-changing customer needs.

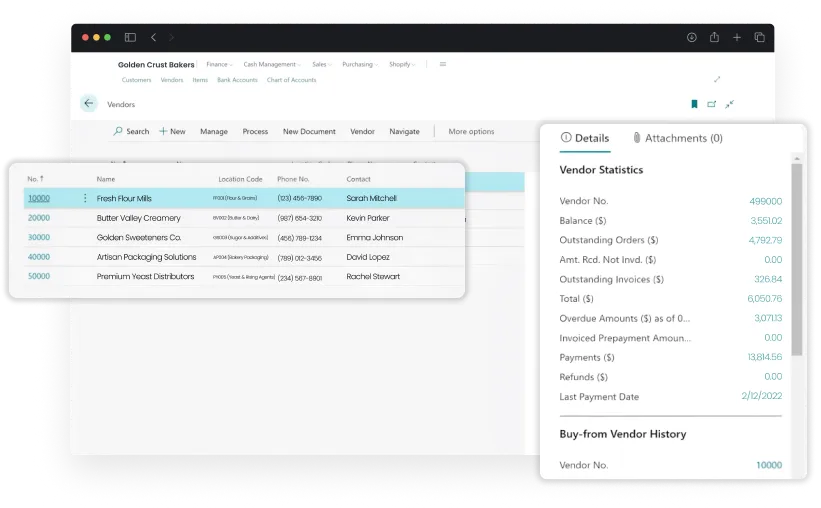

Source Smarter, Spend Better, and Stay Compliant

Streamline supplier management, purchase orders, and inbound quality checks with our ERP software for seafood. Gain complete visibility on costs, vendor performance, and contracts while ensuring every purchase aligns with production schedules and quality needs.

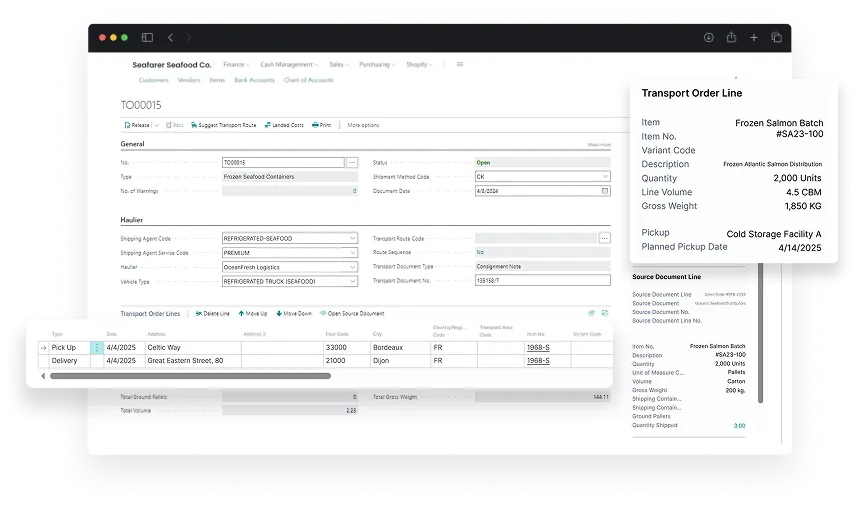

Turn Raw Catch into Profit with Smarter Processing Control

Manage cutting, portioning, grading, and packing with precision. Our seafood ERP software optimizes yields, reduces waste, and ensures product quality so you can maximize profitability without compromising compliance or freshness.

From Hatch to Harvest, Monitor Every Lifecycle

Plan, monitor, and optimize aquaculture operations within our ERP seafood solution. From biomass tracking and feed planning to water quality monitoring and harvest scheduling, gain control of every lifecycle stage for healthier, more profitable yields.

Stay in Control of Stock, Quality, and Shelf Life

Gain real-time visibility into frozen, chilled, and processed inventory with our ERP systems for seafood. Our seafood inventory software centralizes batches, expiry dates, and grades to reduce waste and improve accuracy. With built-in seafood inventory tracking and full seafood inventory management software controls, teams keep stock moving and customers supplied without disruption.

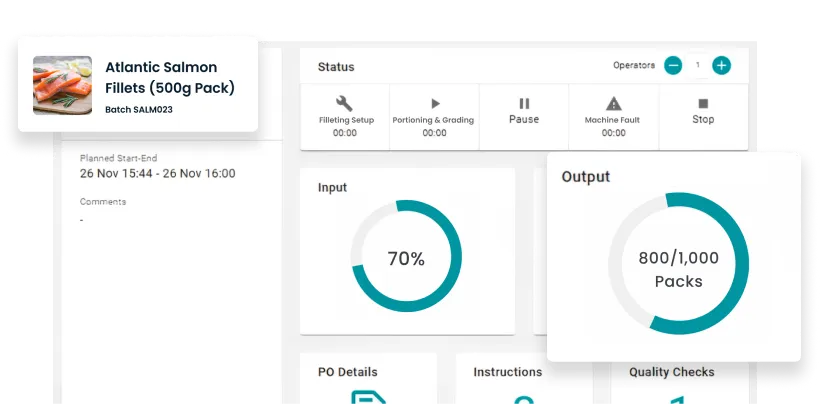

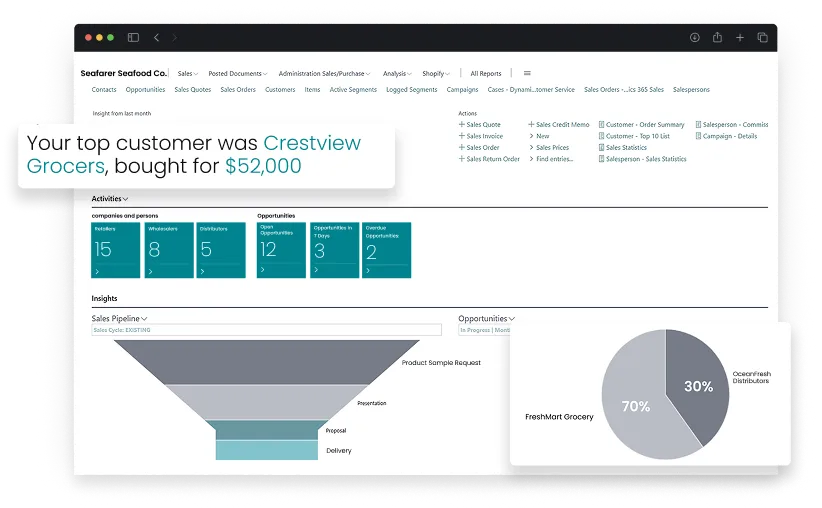

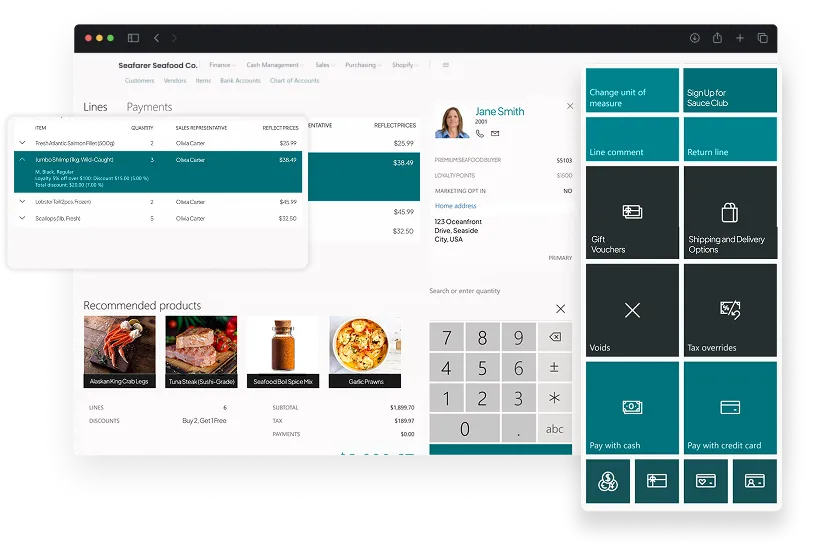

Sell with precision, Even When every Order is Unique

Handle complex pricing, catch-weight sales, and customer-specific requirements effortlessly with our cloud-based seafood ERP. Automate orders, manage contracts, and ensure every sale is traceable and profitable while meeting the tight timelines of the seafood trade.

Accuracy at Every Scan, Compliance on Every Label

Our seafood distribution ERP integrates warehouse workflows with GS1/SSCC label printing and handheld scanning. It pairs naturally with fish supply chain software to improve traceability, reduce errors, and ensure every shipment leaves your facility correctly labeled, documented, and audit-ready.

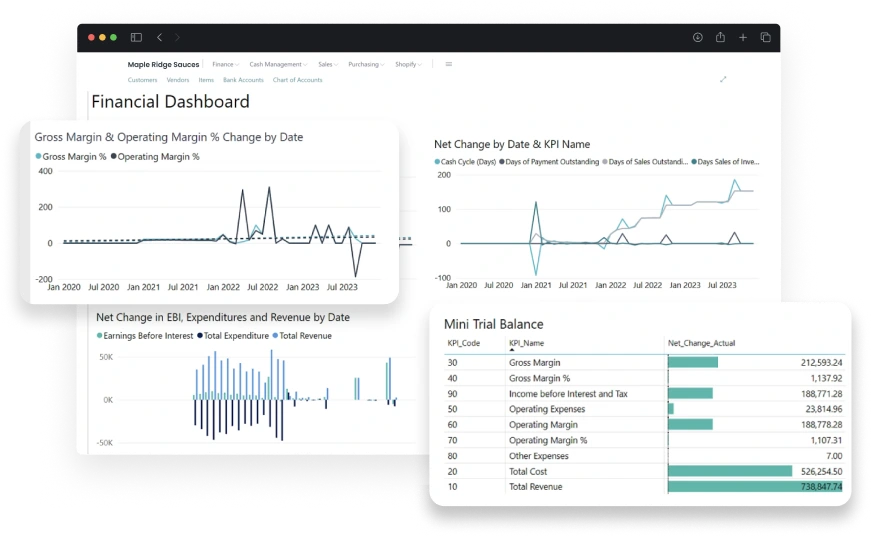

Keep Your Numbers as Fresh as Your Catch

Bring complete financial control into your seafood operations with our erp software for seafood industry. As dedicated seafood financial management software, it supports multi-entity consolidation, cost accounting by batch or vessel, and rolling forecasts that align every dollar with operational performance.

Compliance Built in, not Bolted on

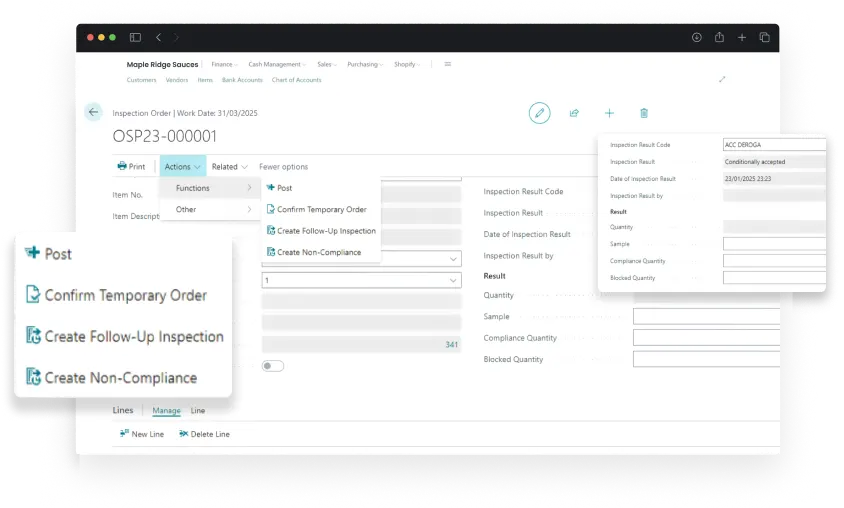

Protect your brand and meet global standards with our seafood ERP. From HACCP and FSMA plans to inspections, allergen labeling, and recall workflows, we make food safety and compliance an effortless part of operations.

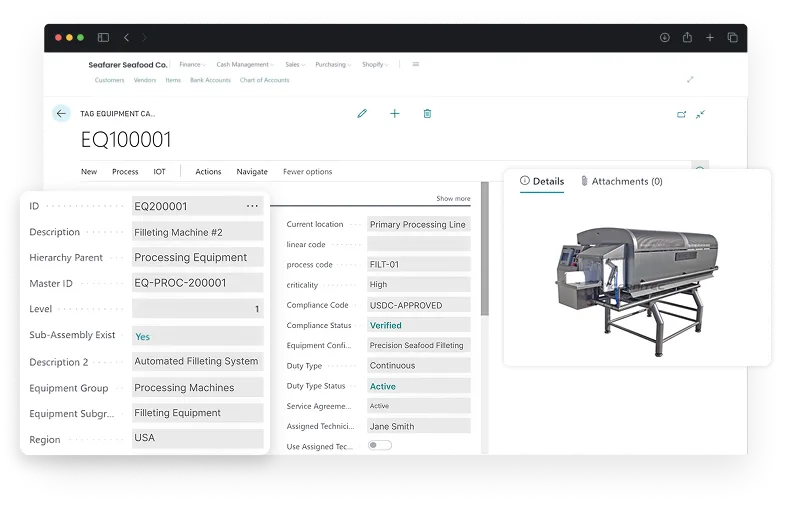

Keep Your Lines Running and Downtime Minimal

Our seafood ERP system integrates asset and plant maintenance, helping you schedule preventive care, track repairs, and manage spare parts, ensuring smooth production flow and fewer costly breakdowns during critical processing cycles.

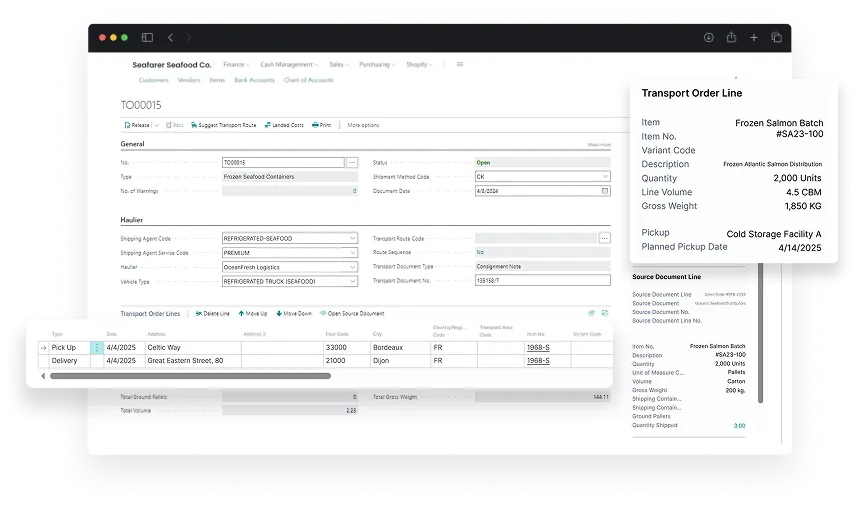

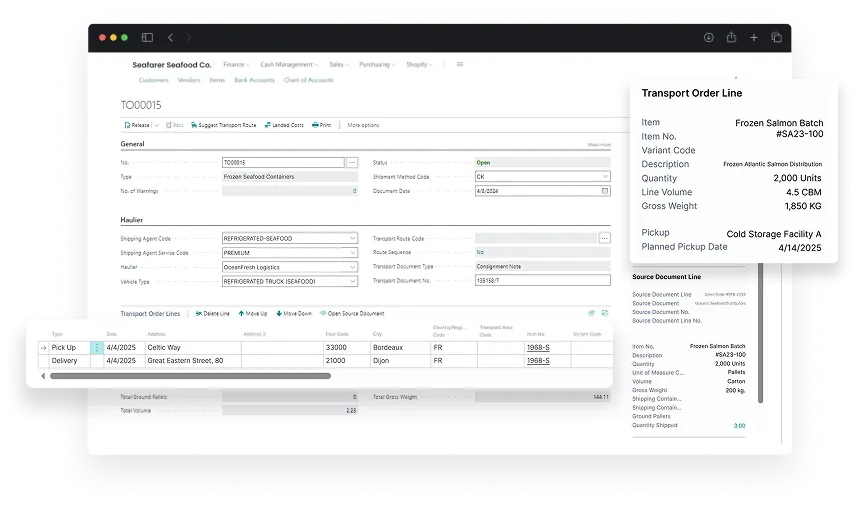

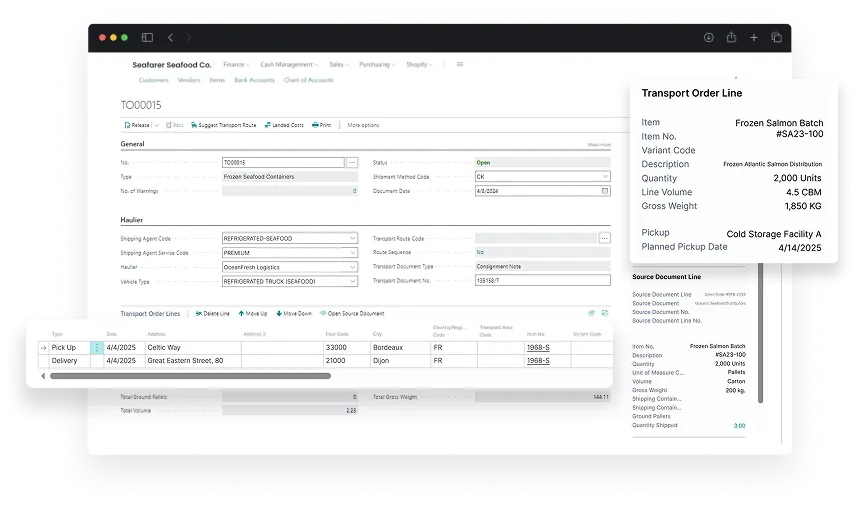

Deliver Seafood Fresh, Fast, and Traceable

Ensure flawless order fulfillment and global reach with our ERP seafood solution. From container tracking and dispatch planning to compliance documentation, manage every movement with transparency, speed, and reliability across your distribution network.

Managing a seafood supply chain means balancing perishability, compliance, and global logistics. Our seafood distribution ERP unifies every stage from harvest and processing to export and retail, ensuring efficiency, transparency, and sustainability across the journey.

Capture data at the source vessels, aquaculture farms, and landing docks. Record species, weights, catch area, crew, and biomass to set the foundation for compliance and downstream supply chain accuracy.

Integrate primary and secondary processing into your ERP: filleting, portioning, grading, and packaging. Ensure maximum yield, minimize waste, and align processing output with market demand and regulatory requirements.

Maintain freshness and compliance across frozen and chilled storage. Monitor temperature, expiry dates, and batch locations to guarantee safe inventory control and prevent losses in seafood supply chain operations.

Streamline outbound logistics with container tracking, dispatch scheduling, and customs documentation. Enable real-time visibility for distributors and exporters while reducing transportation costs and ensuring delivery reliability worldwide.

Meet the strict demands of retailers, restaurants, and export buyers. Manage contracts, fulfill variable-weight orders, and support eco-label requirements to build strong customer trust and long-term market relationships.

Close the loop with complete traceability. Use built-in seafood inventory tracking to follow lots from catch or farm to final sale while seafood inventory management software enforces FEFO and labeling accuracy. Compliance with HACCP, FSMA, and EU regulations becomes routine and brand credibility grows.

In seafood, safety and transparency aren’t just obligations; they are the foundation of global market access and customer confidence. Our ERP software for seafood industry connects compliance, monitoring, traceability, and recalls into one digital safety net. Integrated seafood inventory management software and IoT modules ensure every catch, batch, and shipment meets the highest standards.

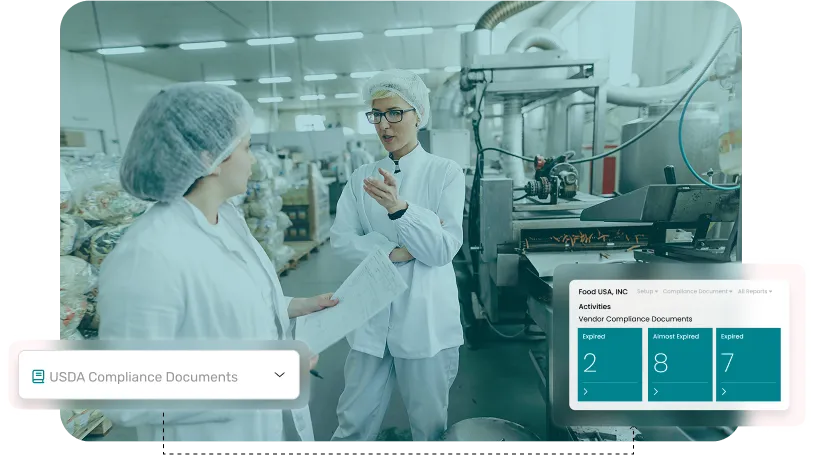

Keep Seafood Operations Audit-Ready, Always

Licenses, catch documentation, eco-label certifications, and species declarations are managed centrally. Instead of scattered paperwork, compliance leaders get a live dashboard of obligations, expiry alerts, and regulator-ready documentation.

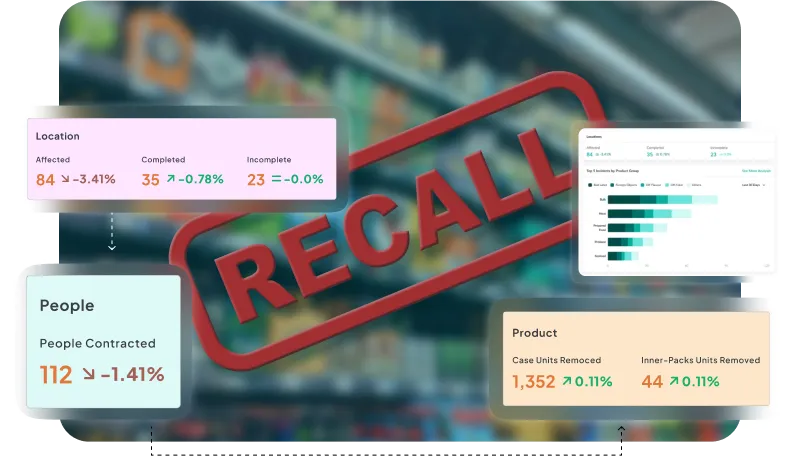

Contain Risk Before it Damages Your Brand

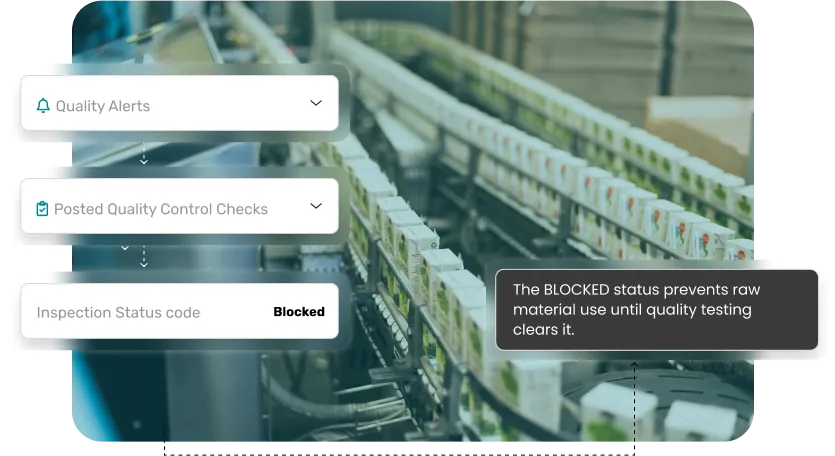

When a quality or safety issue arises, every minute counts. With complete lot genealogy, recalls can be executed in minutes, isolating affected batches and generating regulator-ready reports.

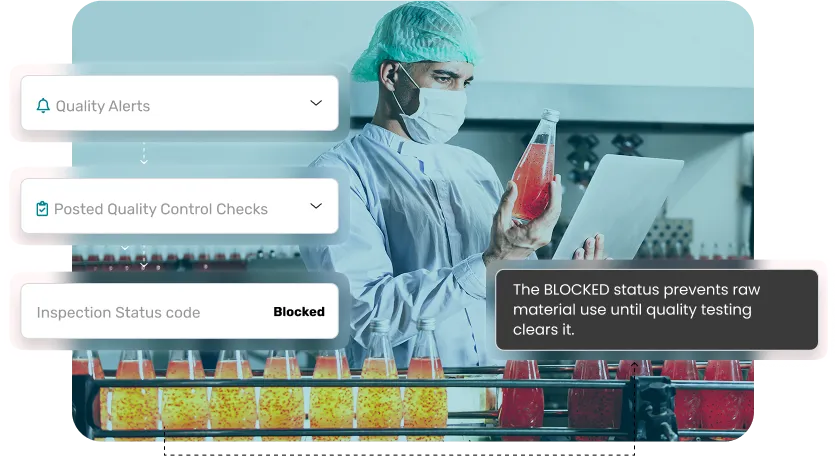

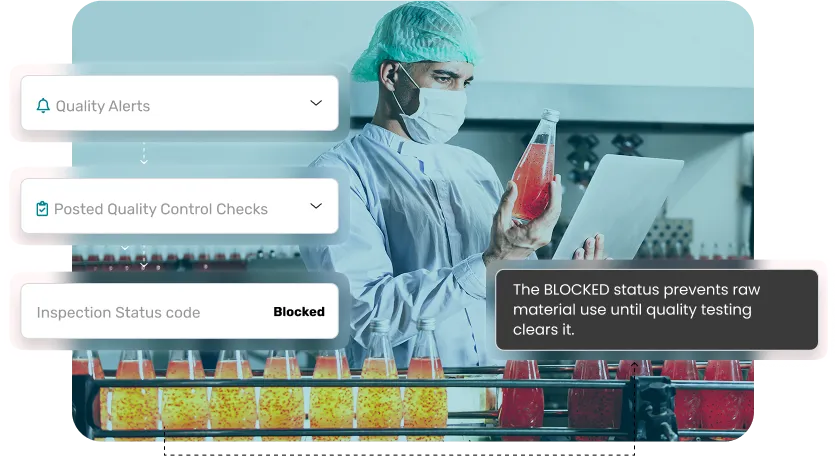

Stop Contamination Before It Reaches the Product

Whether it’s swab testing, allergen checks, or cold-room monitoring, our ERP for seafood turns preventive controls into measurable programs. Hotspots are identified early, and corrective actions are triggered automatically.

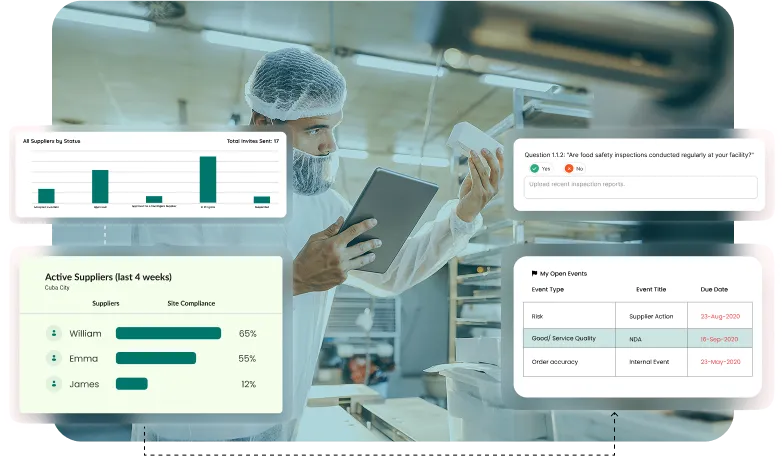

Vitalize Supplier Relationships to Assure Safety from the Source

From fishing vessels to global suppliers, compliance begins before the product reaches your dock. Centralize supplier onboarding, approvals, and certifications to ensure that every incoming lot meets your safety and sustainability standards.

Simplify Global Regulatory Demands With Built-In Controls and Records

Seafood processors and distributors face some of the strictest FSMA controls. Our ERP embeds hazard analysis, preventive controls, and verification into workflows, ensuring compliance without slowing operations.

Keep Every Critical Control Point in Check

HACCP isn’t optional in seafood; it’s survival. Map flows, define CCPs, and monitor critical limits in real time, with deviations instantly flagged for corrective action.

Track Every Lot, Vessel & Batch Without Gaps

Traceability demands in seafood are non-negotiable. Our ERP provides lot-level genealogy across catches, processing, rework, and shipments, enabling instant recalls and transparent audit trails for trading partners.

Build Quality into Every Stage of Seafood Operations

With built-in inspection plans and digital CAPA, quality management becomes proactive. QA teams can prevent issues early, manage holds instantly, and standardize inspections across vessels, plants, and distributors.

From finfish to shellfish, roe, and mollusks, every seafood category brings unique processing, compliance, and market challenges. Our ERP software for the seafood industry is tailored to meet diverse business demands with proven precision, scalability, and traceability.

From salmon and tuna to cod, halibut, and mackerel, finfish require careful grading and high-volume processing. Our ERP optimizes catch-weight handling, production scheduling, and compliance, ensuring efficiency and profitability across domestic and export markets.

Species like shrimp, crab, and lobster demand strict cold-chain control and rapid order cycles. Our ERP delivers real-time freshness monitoring, eco-label compliance, and streamlined sales workflows, helping suppliers maintain quality and transparency for global buyers.

Caviar, salmon roe, and tobiko require specialized handling, precise shelf-life monitoring, and premium export documentation. Our ERP integrates quality checks, lot-level traceability, and compliance reporting to help businesses meet luxury market expectations confidently.

Oysters, mussels, clams, and scallops face sustainability mandates and variable harvest conditions. Our ERP connects traceability, certification management, and processing efficiency, ensuring suppliers meet demand while protecting natural resources and boosting profitability.

Every food business operates differently, whether you’re cultivating, processing, distributing, or manufacturing. With decades of expertise in the food industry, we deliver ERP solutions shaped to your operational realities. Our ERP software for the food manufacturers and processors ensures compliance, efficiency, and growth across every step of the supply chain.

Automate recipe management, allergen tracking, and production schedules to guarantee consistent quality for breads, pastries, and baked goods.

Manage batch precision, allergen safety, and compliance seamlessly while scaling production of chocolates, candies, and sweet treats.

Preserve milk, yogurt, and cheese quality with real-time inventory tracking, automated compliance, and streamlined production processes.

Maintain cold-chain integrity with optimized storage, expiry monitoring, and logistics built specifically for frozen food operations.

Gain control over every cut with lot traceability, food safety compliance, and yield optimization across meat processing workflows.

Oversee hatch-to-harvest operations with flock tracking, batch monitoring, and compliance tools to ensure safe and efficient poultry production.

Standardize formulations, manage allergens, and maintain batch consistency while maximizing efficiency across sauce and dressing production lines.

Ensure freshness from catch to consumer with built-in cold-chain monitoring, lot traceability, and compliance designed for seafood processors and distributors.

With years of hands-on experience across diverse food sectors, we excel in crafting custom-built Seafood ERP solutions tailored from the ground up. If your operations are unique in seafood or across the food industry, we’ll analyze your workflows and design a customized Seafood ERP software that aligns seamlessly with your exact business needs. Our specialists configure every ERP for fish processing module to match your production reality.

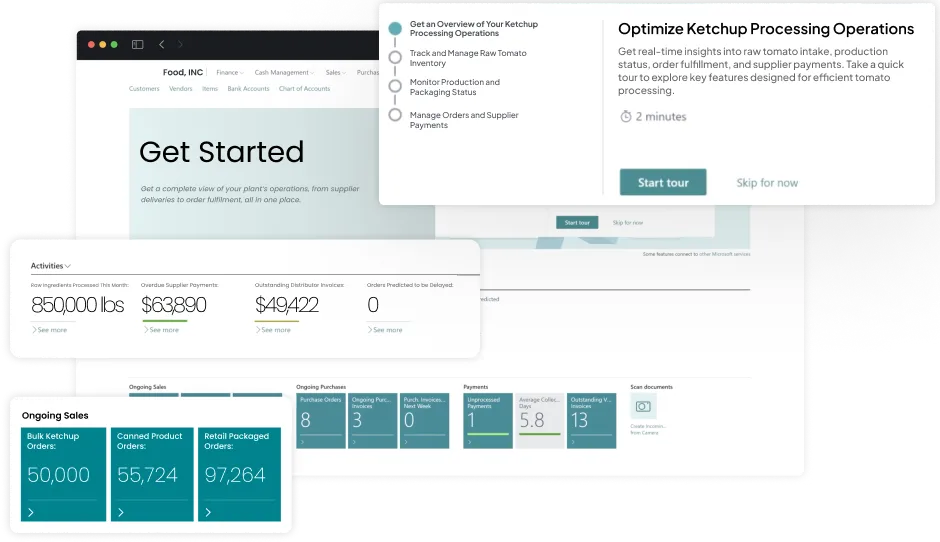

Every food business faces unique challenges from compliance gaps to supply-chain inefficiencies. At Folio3 FoodTech, we’ve helped processors, distributors, and manufacturers revolutionize operations with tailored ERP solutions that drive transparency, efficiency, and measurable growth.

Every seafood business has its own operational view, from variable catch weights to strict cold-chain demands. Our cross-functional experts dive deep into your workflows, uncover risks, and design an ERP for seafood processing that delivers precision, compliance, and measurable profitability. From discovery to deployment, we apply the same agile standards used in our seafood manufacturing software projects to guarantee seamless adoption.

Understanding the Mission before We Begin

In Discovery, we analyze your seafood operations, from catch reporting to compliance hurdles. This phase ensures we design an ERP scope aligned with your real-world challenges and goals.

Turning Insights into a Roadmap for Results

Here, insights become action. We structure modules, milestones, and dependencies so the ERP rollout is realistic, phased, and minimizes disruption to seafood processing operations.

Custom-built for Seafood, not Generic Templates

We configure and extend the seafood ERP system around catch-weight pricing, yield control, traceability, and cold-chain needs. This phase covers custom logic, portals, reports, and UX for floor, warehouse, and finance teams.

Prove it Works before it Reaches Production

We validate every process from traceability checks to cold-chain alerts. Our experts ensure the ERP meets seafood industry standards before it ever reaches your production floor.

One system, Endless Connections

We integrate scanners, IoT sensors, carriers, EDI, finance, and eCommerce so your ERP for seafood runs as one source of truth. You can handle real-time orders, inventory, cold-chain, and compliance data without silos.

Clean, Accurate, and Migration-ready

We profile, cleanse, and stage historical items, lots, suppliers, and financials into a cloud-based seafood ERP with test loads and cutover rehearsals so go-live accuracy is trusted on day one.

Go Live Without the Stress

Deployment is managed with precision to ensure stability, minimal downtime, and confidence that your seafood ERP will run smoothly from day one.

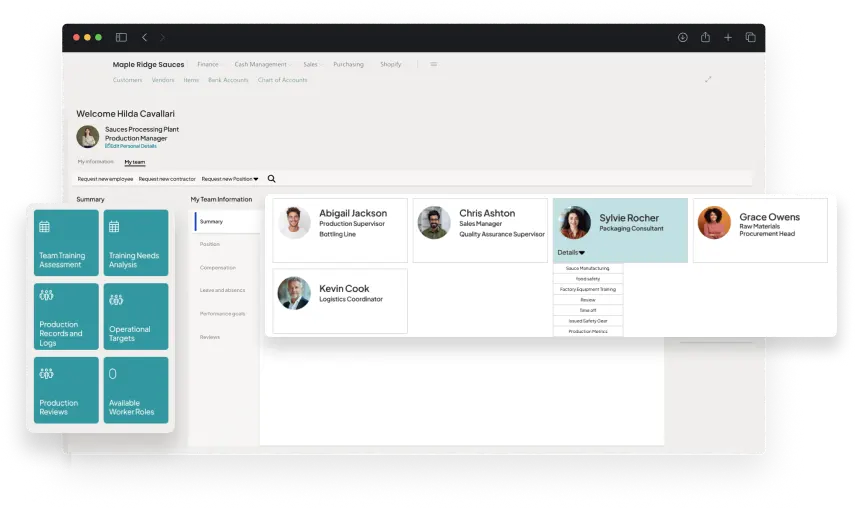

Adoption that Sticks, Support that Scales

We equip teams with hands-on training, SOPs, and continuous support so they adopt the seafood ERP fully, achieving ROI faster and sustaining long-term gains.

Seafood businesses rely on diverse tools from accounting and e-commerce to logistics, retail partners, and more. Our seafood ERP solutions integrate them all into one platform, giving you complete visibility and control without system silos. By linking fish supply chain software and seafood inventory tracking modules with finance and cold-chain systems, your data flows intelligently across departments for faster, more reliable decision-making.

Our clients span fisheries, processors, distributors, and exporters — and their success stories speak louder than promises. From improved compliance to higher yields and smoother operations, discover how our ERP software solutions help businesses thrive across the value chain.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

A seafood ERP is purpose-built to manage industry-specific needs like catch-weight pricing, cold-chain monitoring, and lot traceability. Unlike generic systems, it’s designed to solve compliance, freshness, and profitability challenges unique to seafood businesses.

ERP software empowers seafood businesses with complete control over purchasing, processing, inventory, sales, and logistics. By unifying operations, it delivers real-time inventory visibility, full product traceability, and rigorous quality assurance. The result is streamlined workflows, minimized waste, stronger compliance with food safety standards, happier customers, and higher profitability in a fast-moving, highly perishable seafood market.

Key features to look for in a Seafood SERP include traceability, food safety compliance, catch-weight automation, supply chain visibility, and integrations with scanners, eCommerce, and logistics platforms. These ensure smooth operations and better margins across the seafood value chain.

The seafood ERP system automatically calculates costs by actual weight and grade, eliminating manual errors. It ensures fair pricing, accurate invoices, and stronger profitability for processors, distributors, and exporters handling variable seafood products.

Yes, seafood ERP provides instant lot-level genealogy so you can trace products backward and forward in seconds. Mock recalls, regulator reports, and real-time alerts make compliance fast and straightforward.

An ERP for Seafood digitizes HACCP plans, manages preventive controls, and automates audit documentation. Compliance tasks become part of daily workflows, helping you meet FSMA, EU, and FDA requirements with ease.

Seafood ERP automates customs documents, flags FDA holds, and tracks shipments from port to plant. You gain visibility and avoid costly delays in global trade and distribution.

Implementation is phased: discovery, planning, configuration, integrations, data migration, and training. Timelines vary by scope, but our structured process ensures value delivery with minimal disruption.

Yes, seafood ERP reduces spoilage, improves yield tracking, and prevents compliance fines. With automated workflows, businesses save time and costs while enhancing margins across every operation.

A seafood ERP embeds inspections, non-conformance logging, and CAPA workflows into daily tasks. It ensures only quality-approved seafood moves forward, protecting your brand and customer trust.

Yes, handheld scanning and compliant label printing are built in. It improves inventory accuracy, accelerates dispatch, and ensures regulatory labeling standards are met consistently.

With seafood distribution ERP, you can track containers, shipments, and deliveries in real time. It reduces errors, supports global exports, and strengthens customer confidence in your supply chain.

Seafood ERP supports eco-labels, certifications, and carbon tracking. Businesses can monitor sustainability metrics, meet buyer expectations, and report environmental performance transparently to stakeholders.

Yes, seafood ERP scales with your growth. Whether you’re a small processor or a global distributor, modules can be tailored to fit your size and needs.