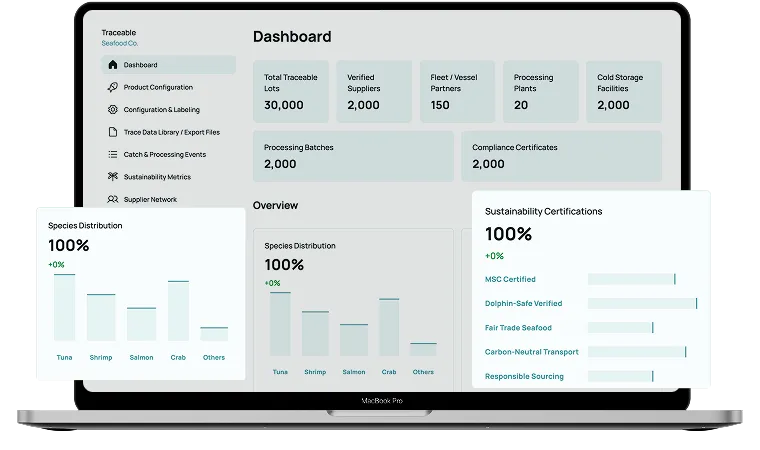

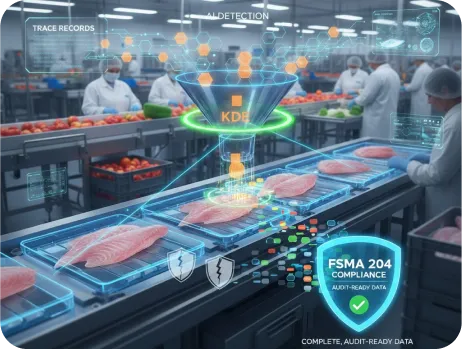

Get the world’s first seafood-native, AI-powered traceability system built for processors, connecting FSMA 204 compliance and processing data from dock to distribution. It doesn’t just track data; it interprets, predicts, and proves every link in your chain.

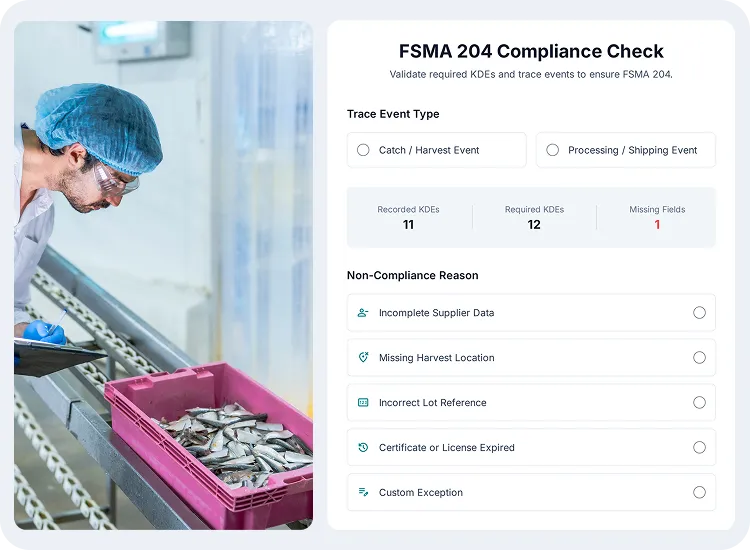

When trace data lives in silos, blind spots grow. With smarter seafood traceability software, you get the ability to validate KDEs, maintain FSMA 204 compliance, and prove product integrity at every checkpoint.

Meet FSMA 204, GDST, and international traceability standards effortlessly with automated recordkeeping, verified KDEs, and instant digital audit readiness.

Gain end-to-end seafood supply chain traceability from vessel to buyer, tracking every lot movement, processing event, and certificate to eliminate blind spots.

Use the seafood traceability system to generate audit-ready trace reports in seconds. Verify KDE completeness instantly, and respond confidently to FDA or third-party inspections without operational delays.

Authenticate product origin, species, and documentation through AI validation and GDST data exchange to prevent substitution, tampering, or fraudulent claims.

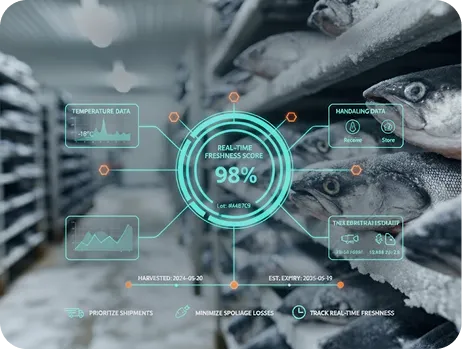

Connect trace data with temperature sensors and inventory logs to monitor freshness, reduce spoilage, and optimize product rotation across seafood processing facilities.

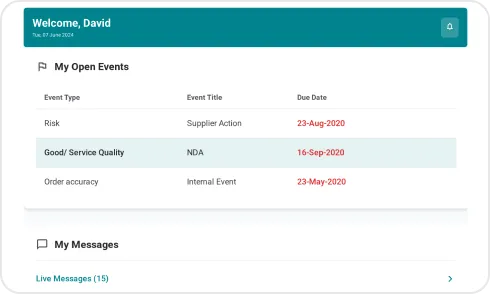

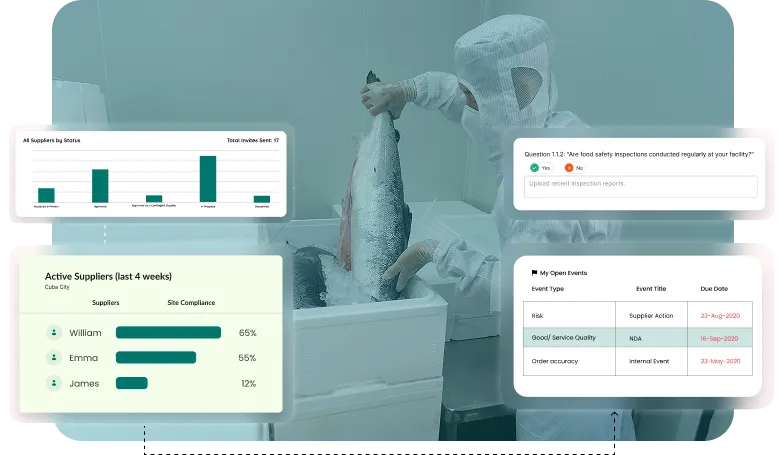

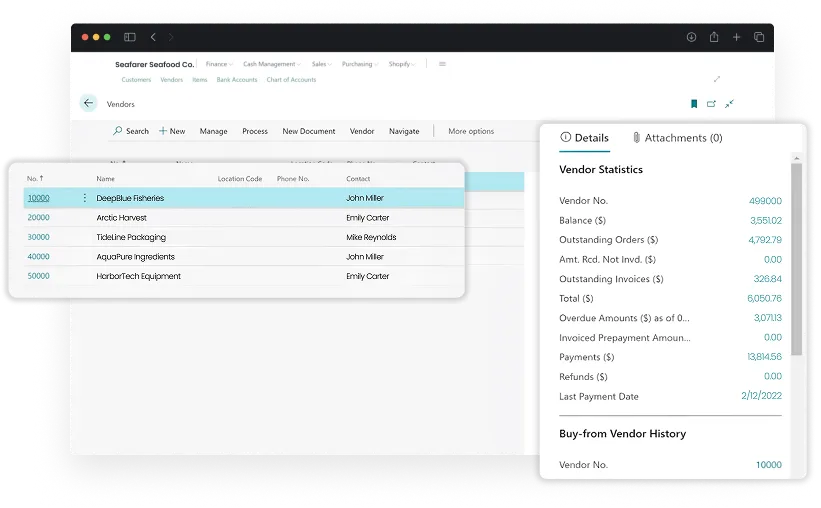

Onboard every supplier into a shared seafood traceability system, standardize data submissions, and track compliance performance through risk-based supplier scoring.

Prove sustainability, authenticity, and compliance through transparent trace records that provide export approvals, retailer partnerships, and consumer confidence worldwide.

Achieve food safety compliance through seafood traceability software that integrates vessel data, batch lineage, and KDE validation under an interoperable ecosystem.

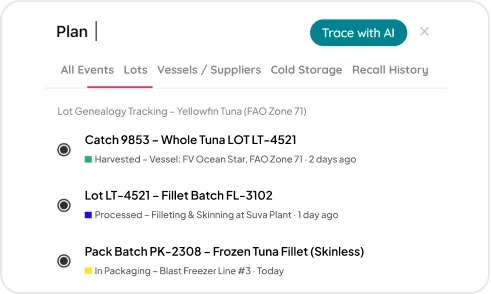

Visually map complete parent–child lot relationships from catch through processing, merges, splits, and shipments for traceability.

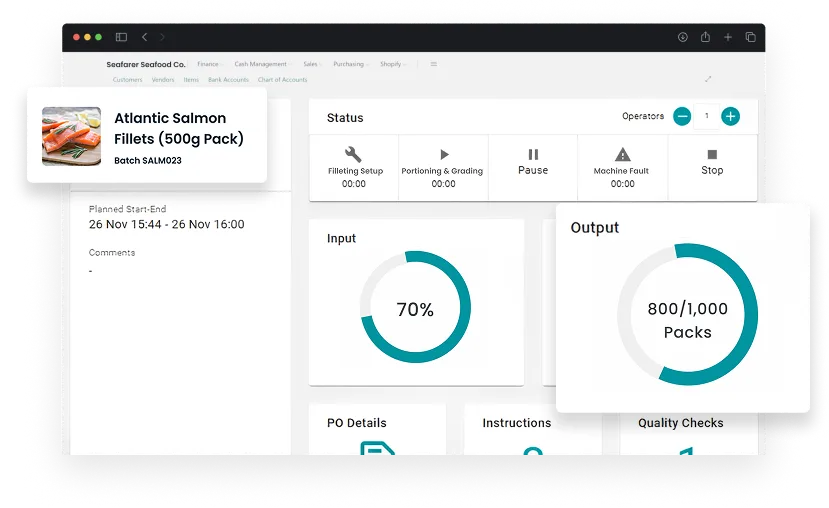

Capture every processing step via mobile or tablet (operator ID, equipment usage, yield data, timestamps) to eliminate manual workflows and trace gaps.

Validate required KDEs per CTE; auto-flag gaps, generate FDA-ready trace records, and maintain SIMP-aligned documentation.

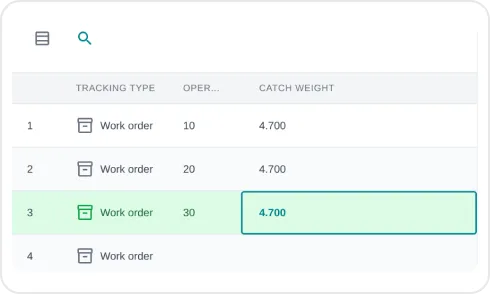

Capture live weights from scales; reconcile variances to lots and labels, and preserve GS1 units in EPCIS.

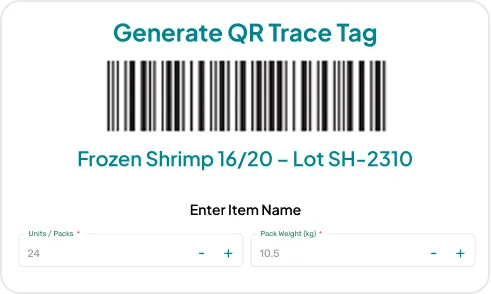

Create GS1/EPCIS trace codes and QR-enabled labels linked to digital lot records, allowing downstream partner and consumer visibility instantly.

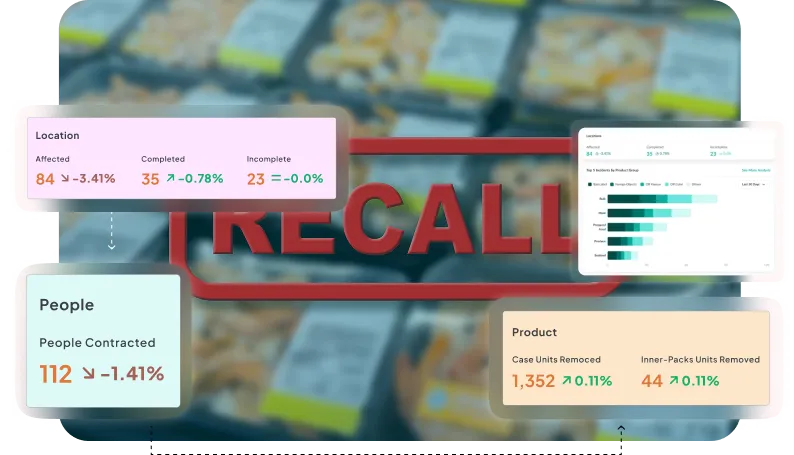

Model trace links, supplier chains, and customer shipments to simulate recall scenarios, notify impacted nodes, and audit response readiness.

Invite suppliers to submit KDEs, certificates, vessel details; apply validations, assign risk scores, and automate GDST-formatted exchanges.

Ingest IoT temperature and humidity into events; alert breaches; calculate per-lot freshness scores and shelf-life estimates.

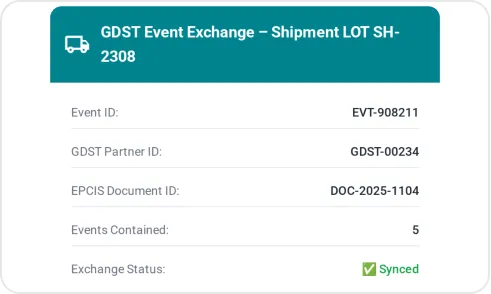

Exchange trace events with partners via GDST v1.2 and EPCIS 2.0; ensure interoperable, standards-based mapping.

Protect seafood quality with a powerful suite of food safety solutions, enabling rigorous compliance checks, real-time monitoring, and full traceability from catch to consumer.

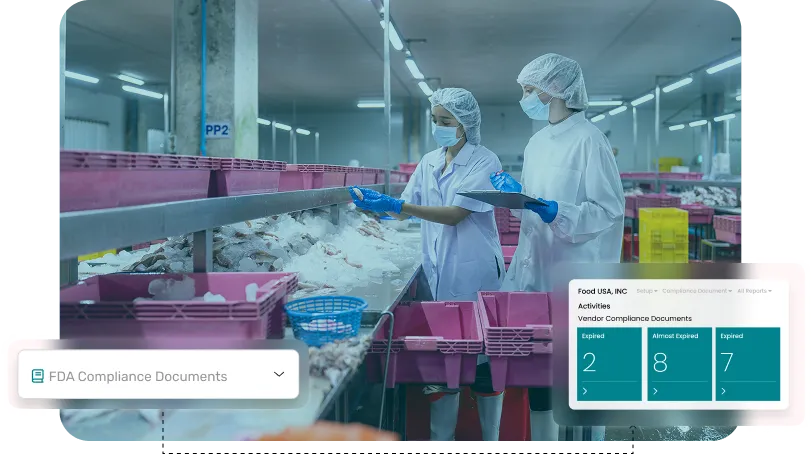

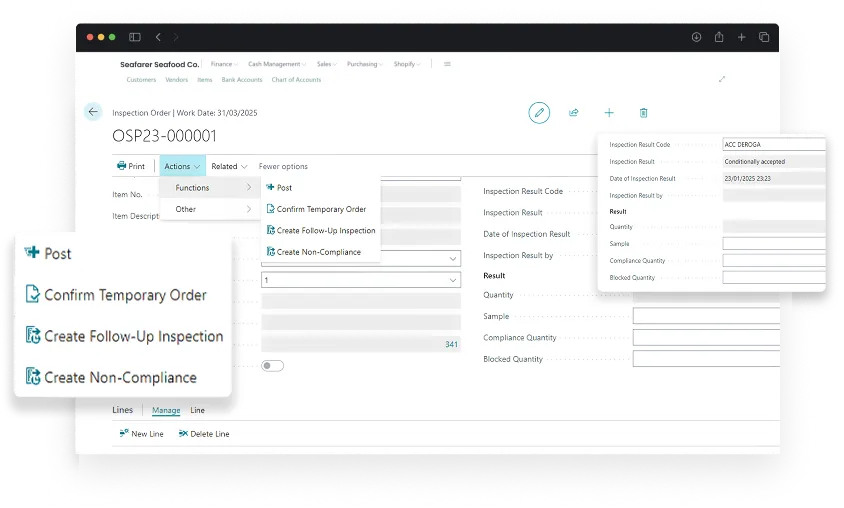

Ensure compliance with FDA Seafood HACCP, FSMA 204, EU, and global seafood safety standards. Automate critical control point (CCP) monitoring for temperature, handling, and pathogen risks.

Track histamine, listeria, mercury, and biotoxin levels in real time. Automate organoleptic tests, cold storage validation, and rapid microbial detection to maintain seafood freshness and export compliance.

Vet suppliers for sustainable fishing, antibiotic-free aquaculture, and legal sourcing. Automate vendor certifications, import documentation, and COA checks to prevent fraud.

Accelerate seafood recalls with automated batch tracing, pathogen alerts, and withdrawal workflows. Instantly identify contaminated lots, notify distributors, and meet seafood safety recall mandates.

Detect anomalies, predict cold-chain risks, and improve compliance accuracy using advanced AI capabilities within seafood traceability software.

Identify and fix missing KDEs instantly across trace records to maintain FSMA 204 compliance and ensure complete, audit-ready data.

Evaluate supplier reliability and compliance performance with automated AI scoring to make smarter sourcing, approval, and audit decisions.

Confirm product authenticity by uploading or scanning labels and images, instantly verify species type, catch origin, and packaging accuracy.

Track real-time freshness scores for each lot using temperature and handling data to prioritize shipments and minimize spoilage losses.

Run AI-driven recall simulations to visualize which batches, customers, or regions would be affected, and act before issues escalate.

Convert partner data into GDST/EPCIS-ready formats, so you can share, import, and export trace records without manual reformatting.

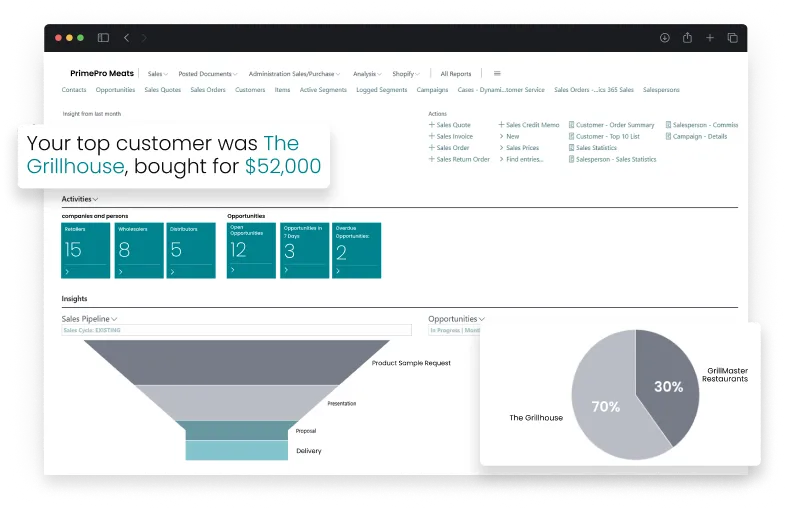

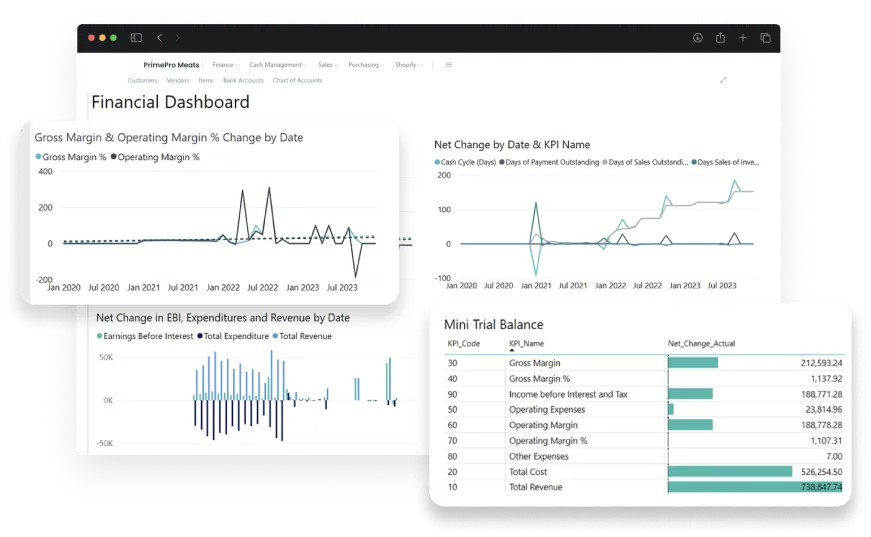

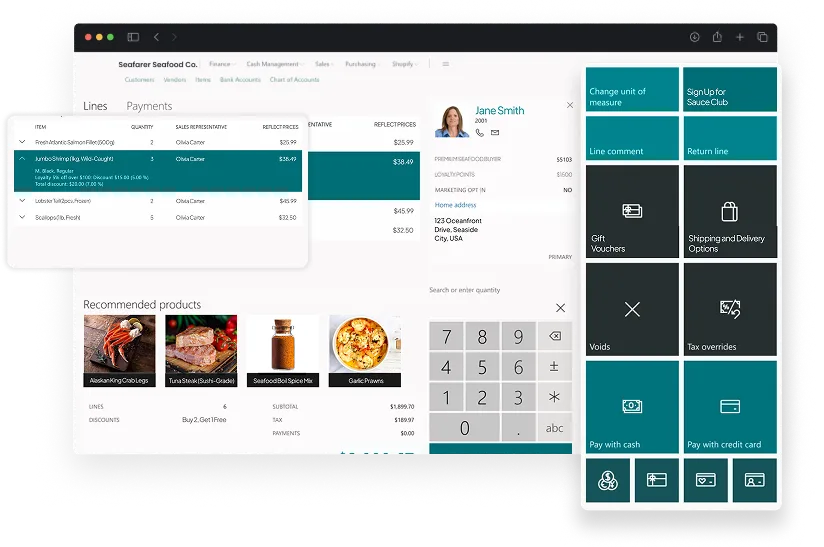

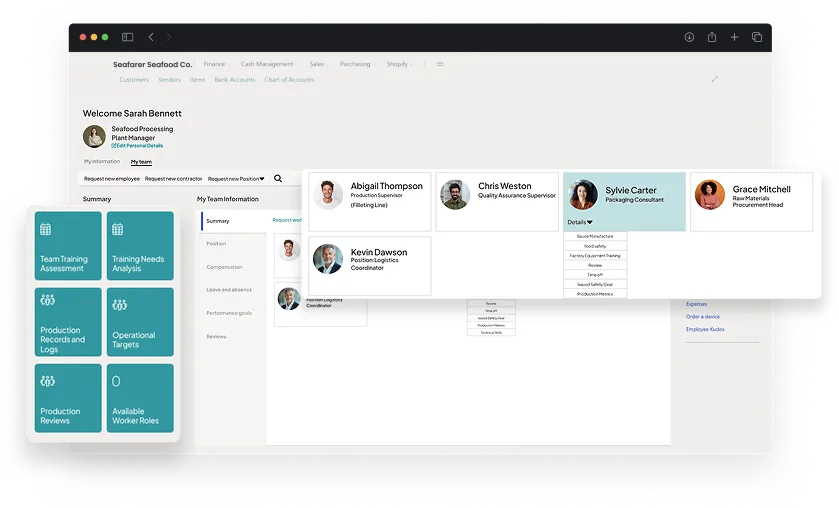

Beyond seafood traceability, trace your performance with an ERP that helps you manage every seafood operation, from processing and inventory to quality and finance, all in one integrated system.

Exchange trace events effortlessly with partner systems, ERPs, and certification databases through GDST- and EPCIS-compliant integrations in traceability software for seafood industry.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

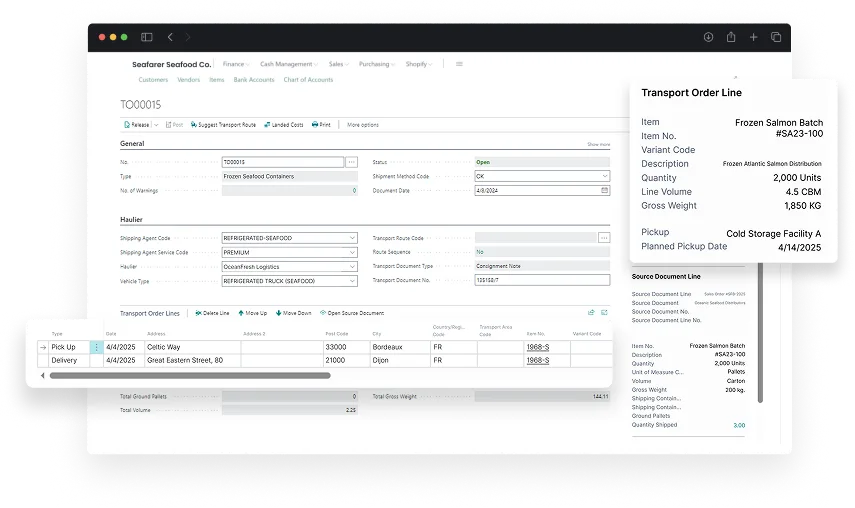

Seafood traceability solutions by Folio3 FoodTech give processors a connected view of every product journey, from vessel landing to export delivery. Each lot and shipment is digitally linked with time, weight, and quality data, providing a continuous, verified record across all departments. By integrating production, cold-chain, and compliance data into one ecosystem, it eliminates visibility gaps and builds complete confidence in every transaction.

The system starts by capturing vessel landing information such as trip IDs, species, and harvest zones, automatically generating batch records upon intake. As products move through grading, processing, packaging, and storage, each step is logged as a digital trace event with operator and timestamp data. Cold storage integrations then update inventory and temperature logs in real time, ensuring complete trace continuity from intake through distribution.

A seafood traceability system records every Critical Tracking Event, including vessel offloading, grading, glazing, labeling, and export dispatch. It captures Key Data Elements such as vessel ID, species, lot code, and storage conditions to create a complete digital history of each batch. This continuous audit trail managed in seafood supply chain traceability software lets processors trace origin, transformation, and delivery details instantly, helping meet both FSMA 204 and buyer documentation requirements.

Folio3 FoodTech’s seafood traceability software is built around GS1 and EPCIS standards, allowing seamless data exchange between suppliers, processors, and buyers. It automates catch certificate creation and links each document to its respective lot and export record. By validating Key Data Elements and ensuring trace event completeness, it keeps processors FSMA 204-compliant while simplifying record retrieval for audits and inspections.

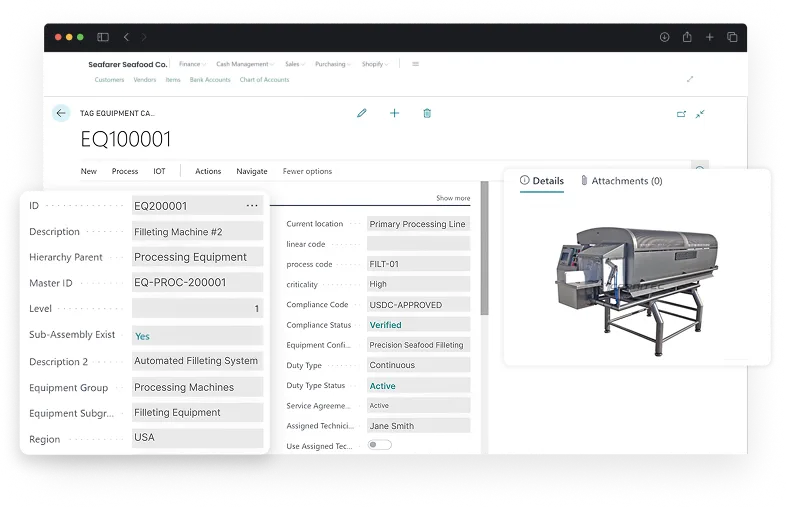

ERP integration connects traceability data directly with production, costing, and inventory modules, giving processors a single view of operational and financial performance. Every lot movement automatically updates stock levels, yield calculations, and associated costs, eliminating manual reconciliation between systems. By combining batch-level trace data with ERP for seafood traceability, processors can identify margin leaks, track shrink by product type, and link compliance accuracy to overall profitability.

Digital transparency tools by Folio3 FoodTech let processors share verified catch details, such as vessel ID, harvest zone, and certification data, through QR codes or secure buyer portals. Each scan or link provides authenticated information directly from the traceability record, ensuring data consistency across buyers and partners.

Implementation begins with a trace data audit and migration plan to bring existing records and supplier information into the new system. Next, on-site device setup connects scales, scanners, and cold-chain sensors for real-time data capture. Once core workflows are configured, teams are trained on digital batch creation, labeling, and reporting tools. The rollout follows a phased approach, starting with one facility or product line, before scaling across processing and distribution sites.