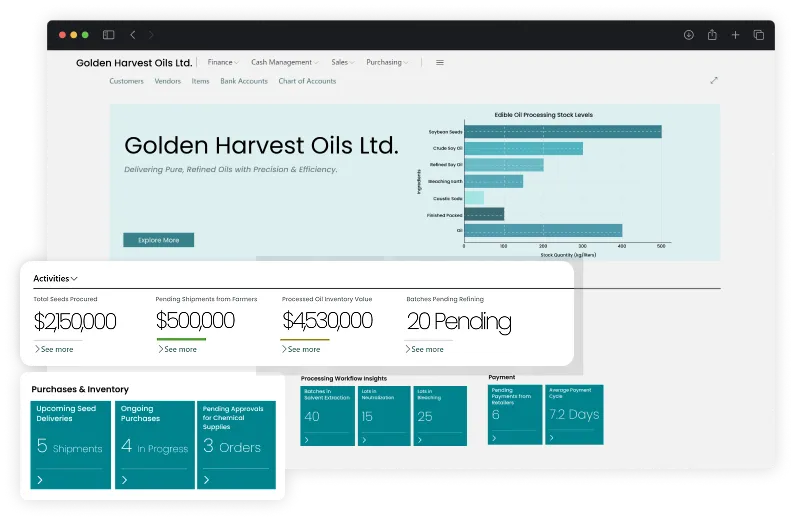

Run your business end-to-end with edible oil processing ERP. From seed intake to refining, bottling, and distribution, integrate every stage to produce consistent, profitable edible oil products.

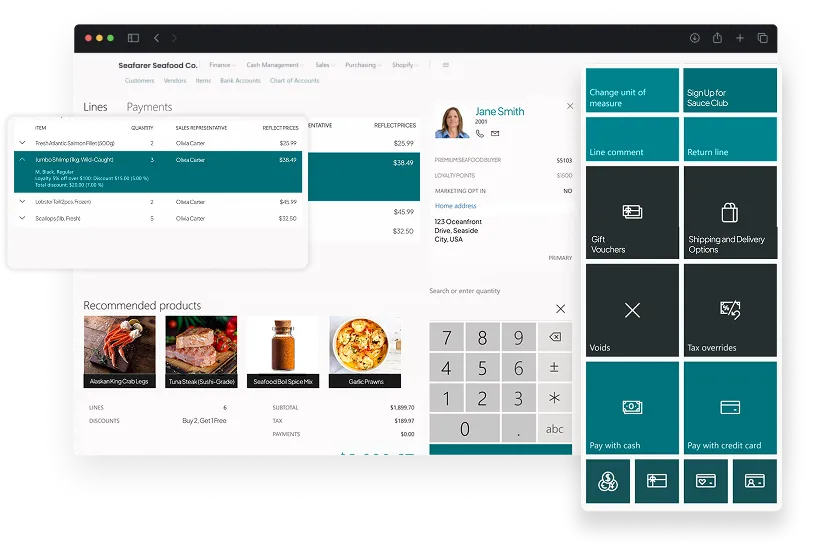

Customize seafood ERP to fit your operation - select only the modules you need and configure them to work smarter and faster.

Gain precise control over oil recovery, refining efficiency, and batch consistency while minimizing losses across crushing, extraction, and processing lines with oil & fat manufacturing ERP.

Control bulk seed and chemical procurement, track oil inventory with density conversions, and align supply planning to volatile demand cycles and refining capacity.

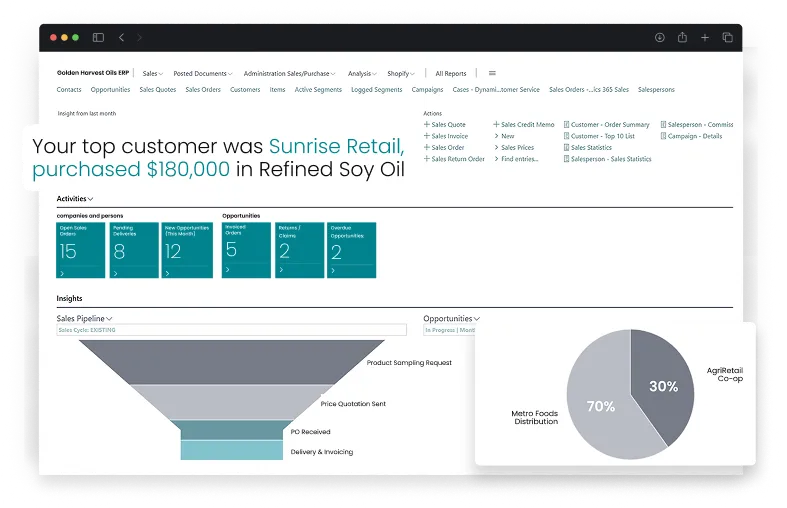

Handle bulk tanker commitments and packaged oil orders with confidence, ensuring accurate pricing, timely invoicing, and reliable fulfillment across volatile edible oil markets.

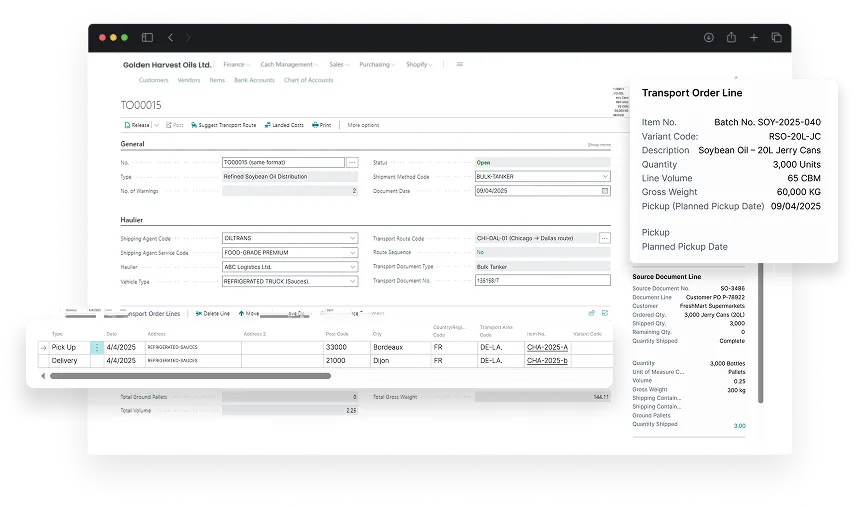

Ensure bulk and packaged oil move efficiently from refineries to markets, minimizing transport costs while protecting shelf life, compliance, and customer commitments.

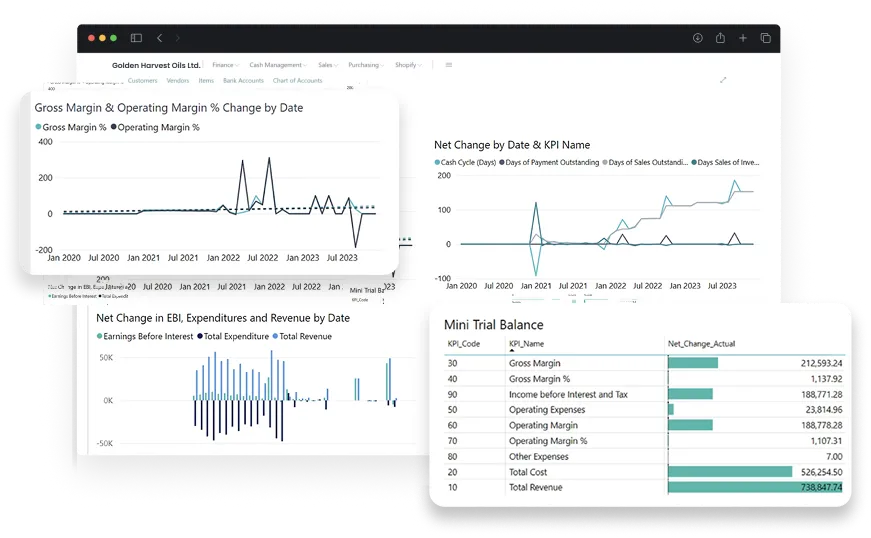

Track refining costs per ton, reconcile bulk shipments and packaging expenses, and gain clarity on true product-line margins.

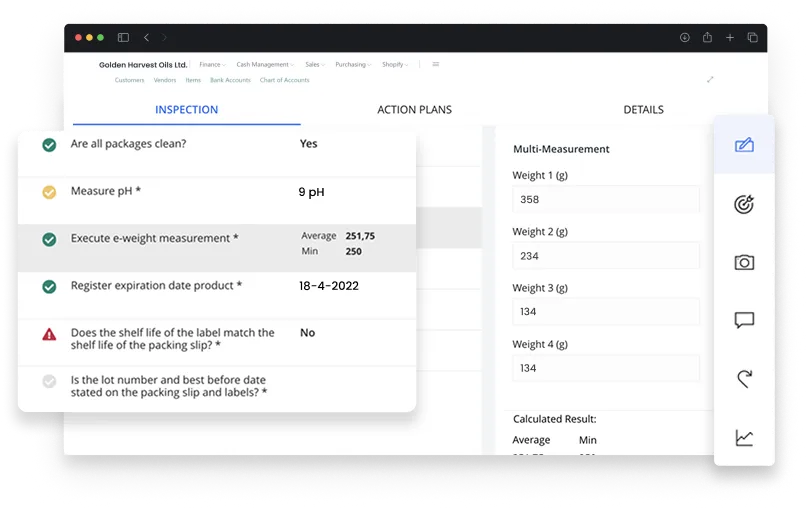

Enforce FFA, color, and moisture standards, and ensure every batch is fully traceable from crude seed oil to packaged delivery.

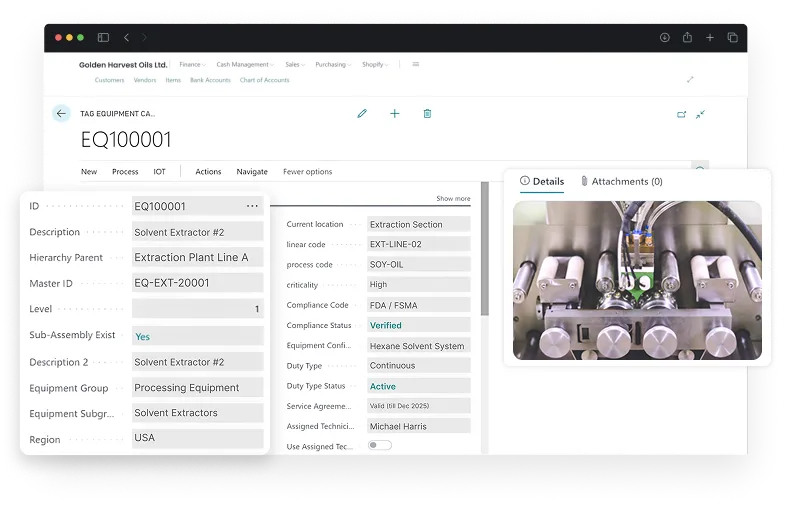

Keep solvent extraction plants, storage tanks, and refining equipment running efficiently with asset maintenance that reduces downtime and prevents costly production interruptions.

Turn plant data into real insight by analyzing oil recovery, chemical usage, utility costs, and profitability trends across batches, lines, and facilities.

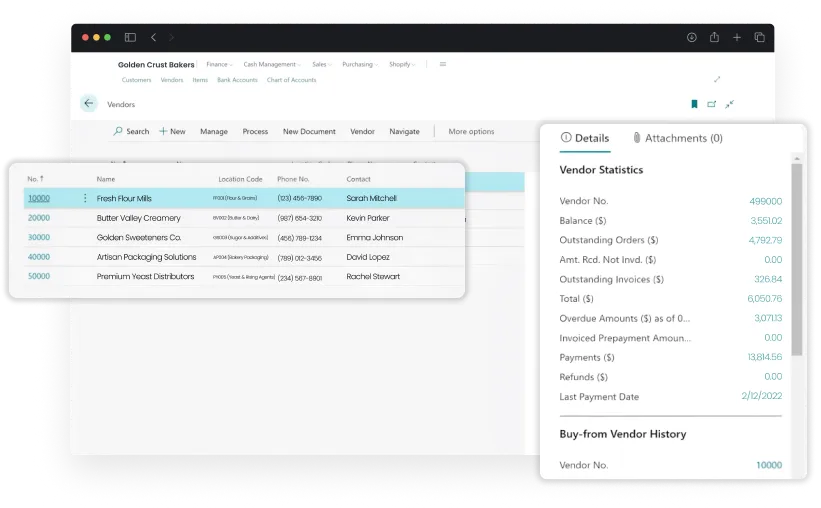

Simplify bulk seed and chemical procurement with transparent vendor collaboration and real-time order visibility.

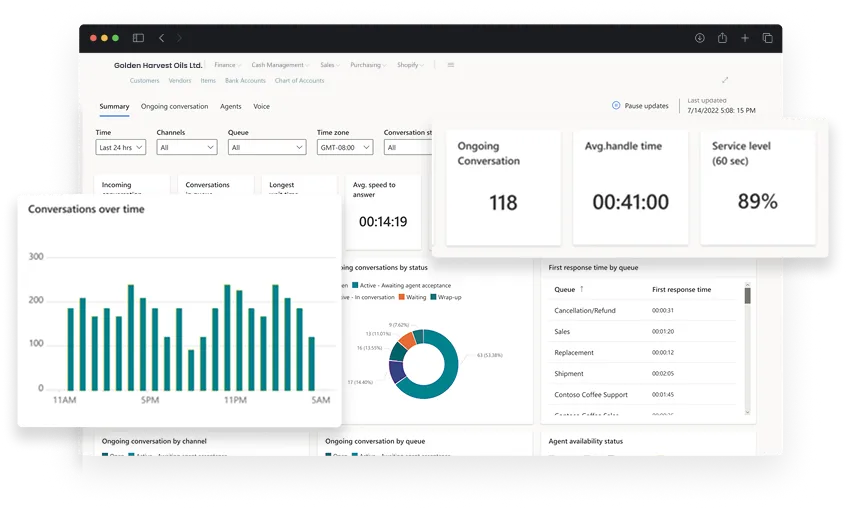

Enable industrial buyers and distributors to place bulk tanker or packaged oil orders directly, track fulfillment, and access invoices through a self-service digital portal.

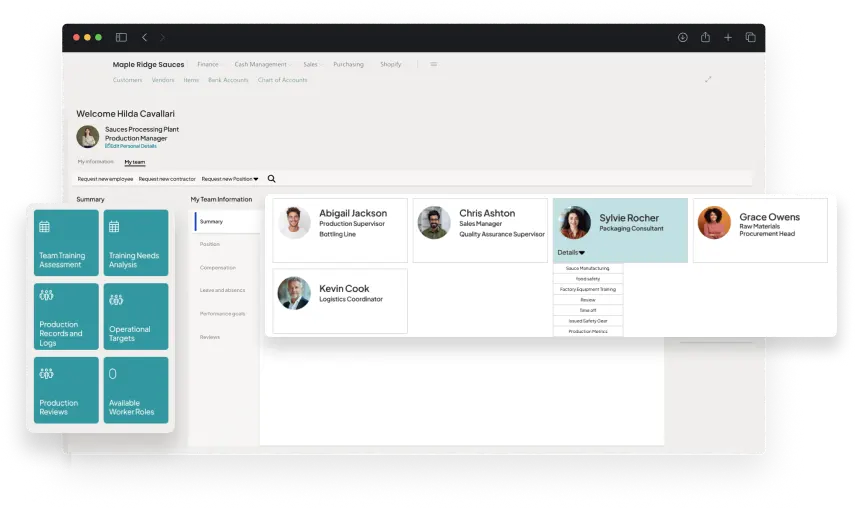

Manage refinery workforce shifts and compliance requirements while tracking labor productivity in processing operations.

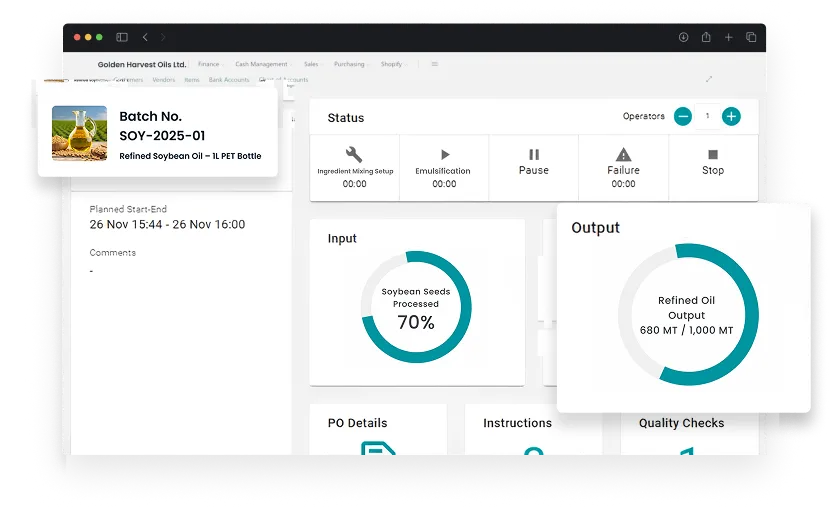

Monitor, optimize, and control all production stages with an edible oil ERP solution for superior quality and efficiency.

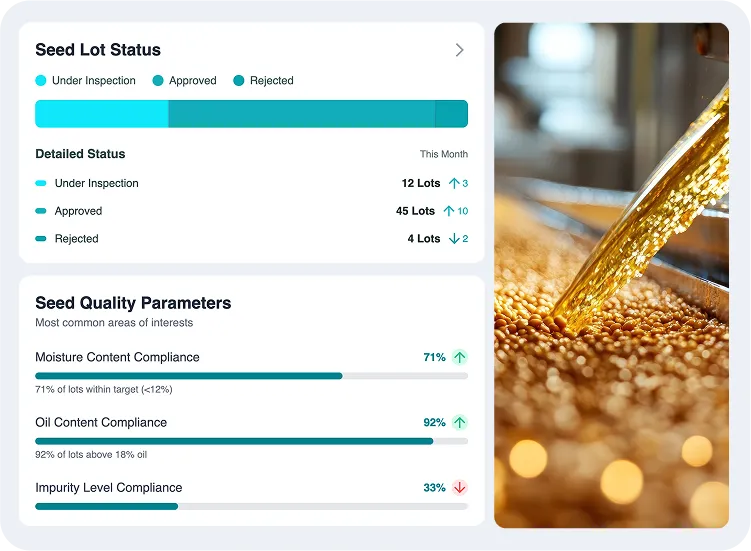

Ensure every seed lot meets quality standards by monitoring moisture, impurities, and inventory in real time.

Maximize yield and reduce losses by tracking pressing and solvent extraction performance across all batches.

Achieve consistent phospholipid removal by controlling dosing, temperature, and retention times automatically.

Standardize FFA reduction and pH stabilization while minimizing oil loss across all neutralization batches.

Remove pigments and trace impurities efficiently by controlling adsorbent usage, contact time, and filtration processes.

Preserve flavor and nutritional quality while removing volatiles through precise control of steam, vacuum, and temperature.

Deliver consistent, market-ready oil by controlling blending, fortification, packaging, and regulatory compliance.

Manage high-yield extraction, clarify crude oil, and optimize fractionation with palm oil software, ensuring consistent quality and efficient storage.

Control dehulling, solvent extraction, and degumming using soybean oil software, tracking protein meal by-products.

Monitor pressing, neutralization, and bleaching processes with canola oil ERP software, maintaining low erucic acid content and stable oil quality.

Optimize cold-pressed or refined sunflower oil production with sunflower oil software, tracking seed quality, yield, and light-stable oil parameters.

Ensure traceable cold-press extraction, acidity control, and filtration using olive oil software, preserving flavor, aroma, and premium quality.

Manage multi-oil processing, blending, and fortification efficiently with vegetable oil ERP software for consistent profitability.

Control cold-press extraction, pulp separation, and refining with avocado oil software, ensuring high-quality, nutrient-rich, and stable oil batches.

Manage copra drying, oil extraction, and fractionation using coconut oil software, maximizing yield, purity, and consistent production output.

Control contaminants, FFA, and moisture while ensuring regulatory compliance in oil production.

Monitor and control critical refining, extraction, and storage parameters to maintain strict adherence to FDA, FSMA, ISO, and international edible oil safety standards.

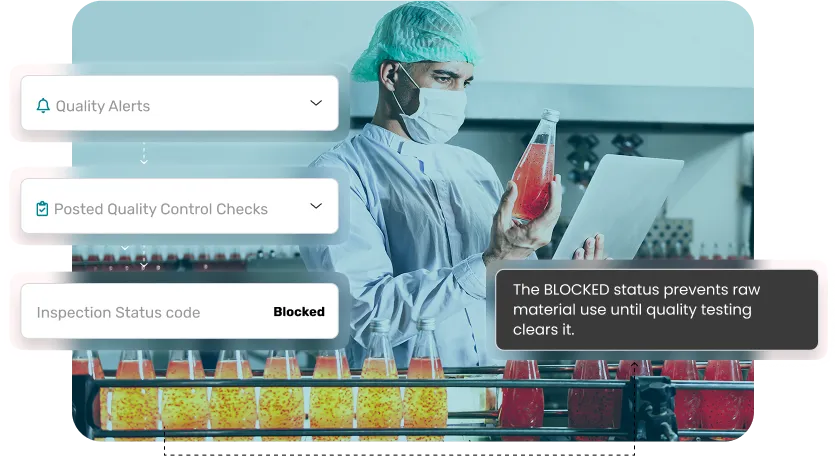

Monitor FFA, peroxide value, moisture, and impurity levels in real time. Automate lab tests, refining parameter validation, and rapid contaminant detection to ensure consistent edible oil quality compliance.

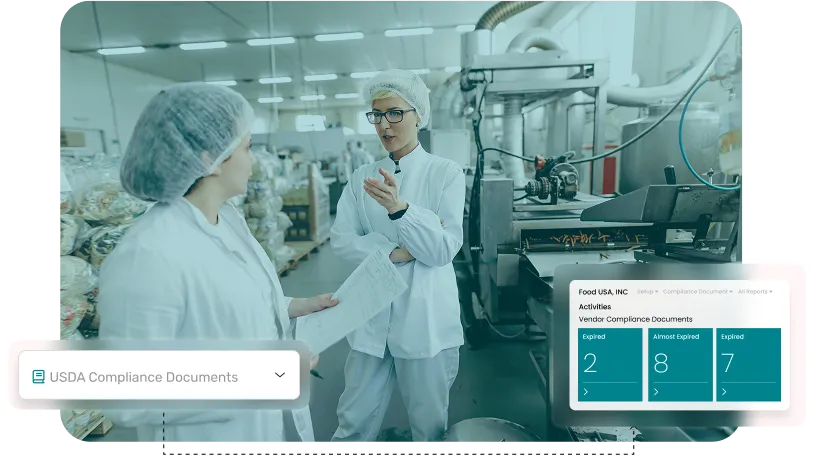

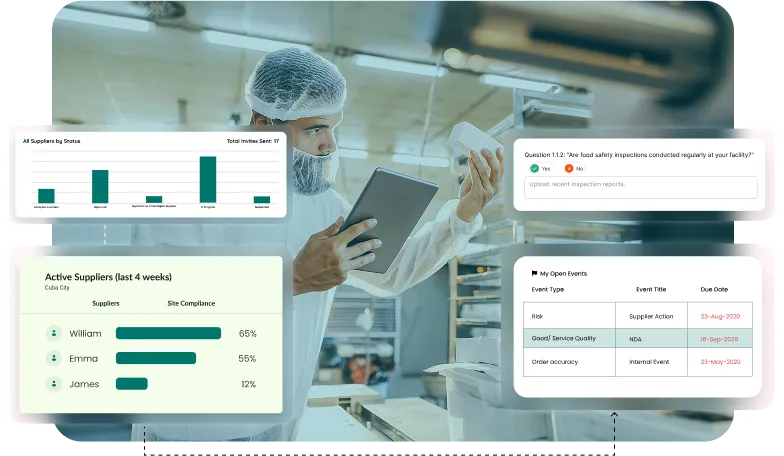

Vet suppliers for certified seeds, sustainable sourcing, and traceable raw materials. Automate vendor approvals, quality certifications, and COA verification to prevent adulteration and ensure consistent oil quality.

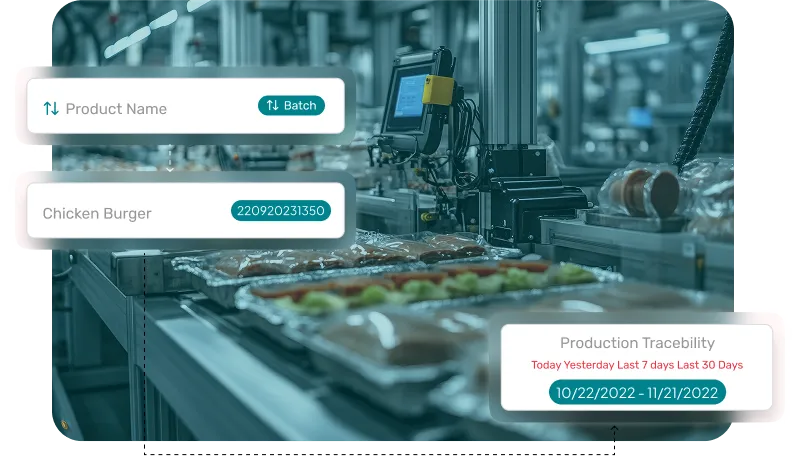

Track every batch from seed intake through crushing, extraction, refining, and packaging. Capture process parameters, lot IDs, co-product flows, and critical control points for full traceability and recall readiness.

Rapidly identify and isolate affected batches across crushing, extraction, refining, and packaging. Automate recall workflows, track lot histories, and ensure regulatory reporting to minimize risk and maintain product safety.

With the edible oil ERP solution, make every batch consistent, every cost tracked, and production fully controlled.

Capture more value from every seed by tracking residual oil, solvent use, and real-time extraction efficiency.

Maintain contract-grade oil by controlling refining recipes, validating FFA and moisture tests, and logging impurities at every batch.

Reduce refinery costs by tracking steam consumption through deodorization and optimizing energy use across every refining cycle.

Track how solvent losses, refining energy use, transport costs, and by-product sales shape profitability for every oil batch.

With edible oil ERP software, connect third-party apps across production, warehousing, and customer order management and eliminate data silos across your business.

Experience hassle-free edible oil ERP software deployment, guiding your plant from setup through ongoing support.

We begin by understanding the oil processing plant’s unique operations and objectives, ensuring the ERP solution addresses production, refining, and quality challenges.

We outline project goals, timelines, costs, and potential challenges while mitigating risks for production data loss and resource management.

We develop edible oil processing ERP to your plant’s specific needs, whether building new workflows, upgrading, or integrating processing-specific modules.

We conduct thorough testing throughout development to ensure accurate yield tracking, process efficiency, and consistent batch quality.

We integrate the ERP software with your plant systems, ensuring smooth data flow between crushing, refining, blending, and packaging departments.

We carefully transfer all production, batch, and inventory data from legacy systems, ensuring accuracy, security, and traceability.

We set up the ERP in a live oil processing environment, ensuring a smooth transition with minimal disruption to operations.

We empower your plant team with hands-on training and ongoing support, ensuring full adoption of the ERP across all production stages.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

ERP software for edible oil processing acts as a single control tower for your operations. Instead of managing seed preparation, refining, bottling, and dispatch in silos, it ties everything together in one system. That means you can track oil quality, throughput, and costs at every stage and make faster, better-informed decisions across the business.

The most valuable ERP features are the ones that directly protect your margins. Yield tracking shows how much oil you’re actually recovering, solvent monitoring ensures safe and efficient usage, and residual oil tests help reduce waste in meal or by-products. Add real-time loss-point alerts, and you’ve got a system that tells you exactly where profits are slipping, and how to recover them.

A refinery ERP must go beyond production numbers and capture the real cost drivers. This includes steam and energy usage, solvent recovery or losses, transport and freight, and even revenue from by-products like meal or lecithin. When all this data is fed into a single system, you see not just batch volumes, but actual batch profitability, helping you optimize both yield and financial return.

The ERP software for both bridges the complexity between bulk oil and packaged inventory. Density-based conversions make sure liters and tons align accurately, FEFO ensures older stock gets used first, and the system distinguishes tank storage from carton or bottle SKUs across warehouses, keeping compliance intact while preventing costly mix-ups.

An oil mill ERP should map the entire journey of a seed. From receiving and grading to cleaning, pressing, and solvent extraction, it records material balances at every step. By-product flows, like meal, husk, or soapstock, are tracked as well, ensuring nothing is lost, miscounted, or underutilized.

Refinery ERP connects directly with your lab information systems, so every FFA, peroxide, or p-anisidine test is tied to production data in real time. With Folio3 FoodTech’s ERP solution, recipes and specifications aren’t just guidelines; they’re digitally enforced. That means operators get immediate alerts if a batch falls outside spec, ensuring consistency, safety, and compliance without slowing production.

The ERP software connects demand forecasting with MPS/MRP, helping you plan production against shifting market conditions. Order promising ties available stock, supplier lead times, and contract commitments together, so even when prices swing, you’re not caught with empty tanks or delayed shipments.

A fats & oils ERP with a built-in B2B portal should let your buyers lock in contract pricing and track rebate eligibility without manual intervention. EDI-driven ordering ensures large distributors can place and confirm orders directly in your system. Subscription scheduling and quick reorders simplify repeat sales, while integrated credit checks, shipping visibility, and automated invoicing make transactions faster and more profitable for both sides.

Palm oil refinery software tracks fractionation yields, deodorizer vacuum/temperature parameters, and ensures RSPO or ISCC sustainability certifications are logged and auditable. Folio3 FoodTech solution brings these controls in one system, reducing compliance risk and maximizing export readiness.

Software for olive oil ensures every lot is tied back to its cold-press batch, with acidity grades automatically recorded and blend ratios monitored in real time. This prevents quality drift while maintaining accurate consumer-label claims.

ERP for coconut and avocado oils must enforce strict cold-press moisture thresholds, monitor filtration cycles, and adapt recipes to multiple packaging formats. Folio3 FoodTech makes these controls actionable, letting processors maintain premium quality while scaling production efficiently.

Folio3 FoodTech’s cooking oil manufacturing software gives processors clear visibility into allergens, automates nutrition and label data accuracy, and connects seamlessly with 3PL partners. This ensures recalls are executed quickly, products remain compliant, and every plant operates with full regulatory confidence.

Shortening and margarine software must track interesterification specs during formulation, enforce QA checks on fat consistency, and align logistics with temperature-controlled storage and transport. Together, these controls safeguard product stability from plant to customer.