With food manufacturing plant maintenance software, equipment downtime is no longer inevitable. Digitize maintenance, protect shelf-life, and maintain audit-ready, uninterrupted production lines.

Drive productivity with food & beverage CMMS Software and empower teams to complete maintenance tasks faster and with precision.

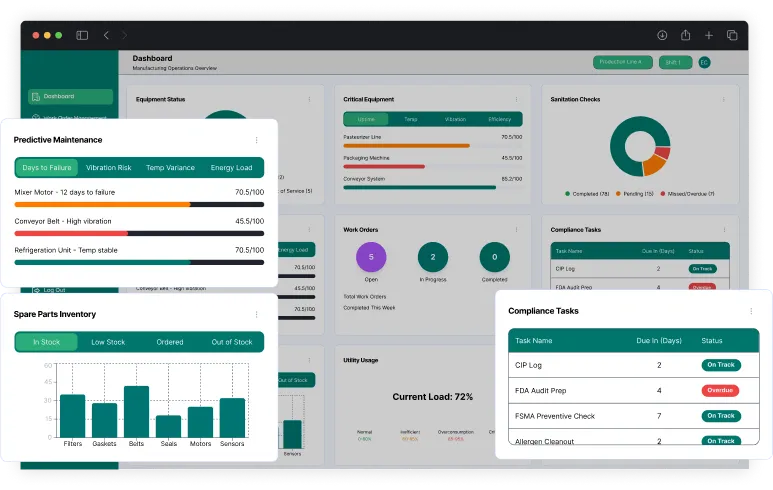

Catch failures early, schedule repairs instantly, and keep peak-season production lines running without unexpected interruptions.

Keep refrigeration units, cold storage, and packaging machinery performing consistently to safeguard product shelf-life and reduce spoilage.

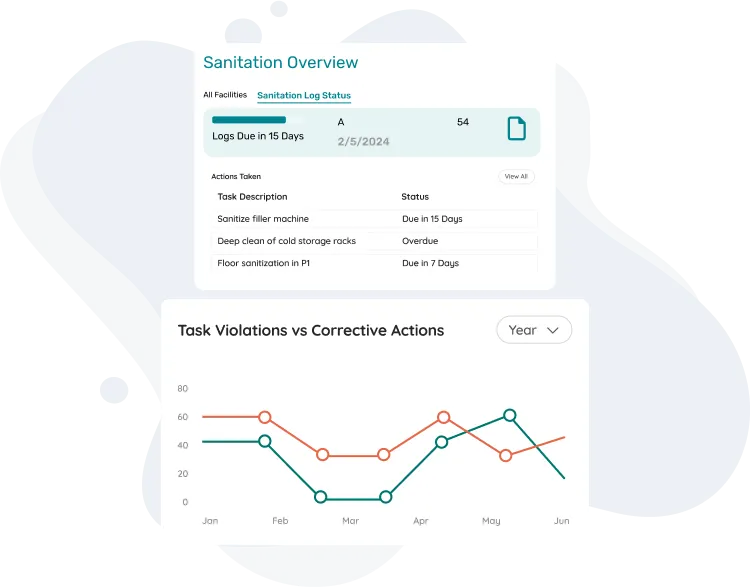

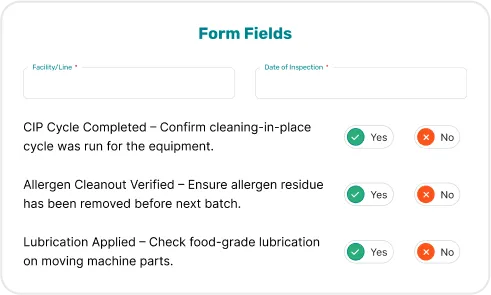

With food processing plant maintenance software, digitally enforce sanitation cycles, hygiene inspections, and CIP validations to avoid contamination and failed food safety audits.

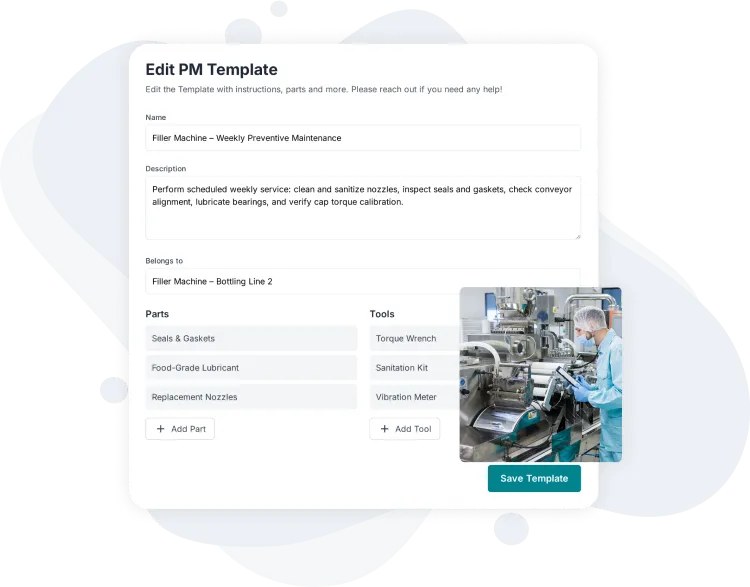

Automate lubrication, calibration, and predictive servicing across pasteurizers, boilers, and mixers to extend asset lifespan significantly.

Track downtime, throughput, and quality in real time to maximize plant OEE across all production lines.

Digitize all maintenance operations with food manufacturing plant maintenance software, ensuring end-to-end oversight and nothing critical is left unchecked.

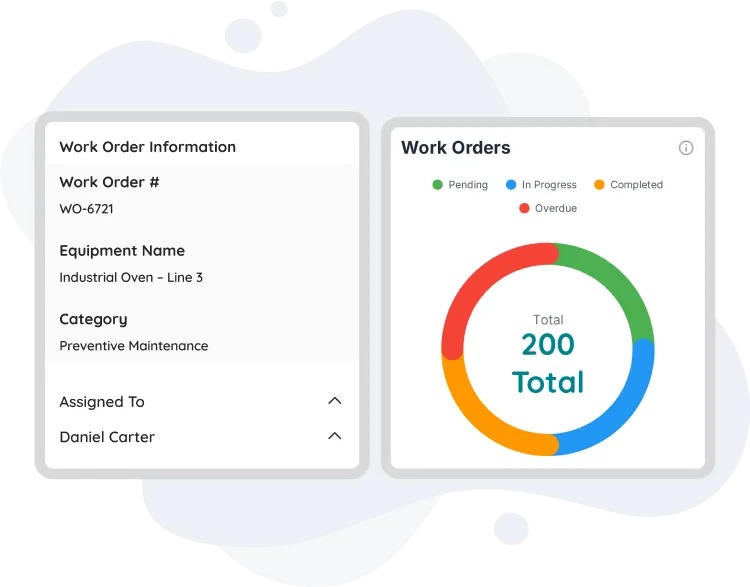

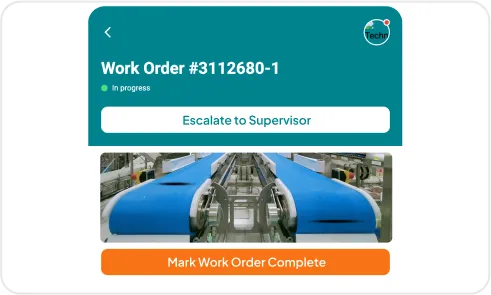

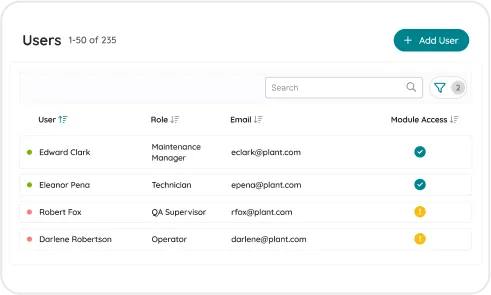

Coordinate, assign, and track all food and beverage plant maintenance tasks with full visibility and compliance-ready documentation.

Ensure scheduled inspections and servicing keep assets compliant, reliable, and downtime-free by using plant preventive maintenance software.

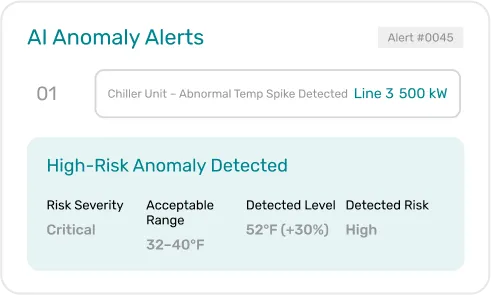

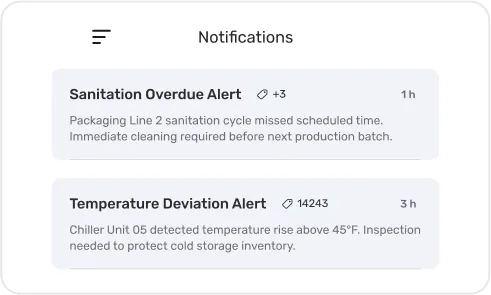

With predictive maintenance software for food & beverage, AI and IoT prevent breakdowns before they impact production.

Digitally enforce cleaning cycles, CIP routines, and hygiene checks for regulatory compliance.

Track and optimize energy and utility use to reduce costs and meet sustainability goals.

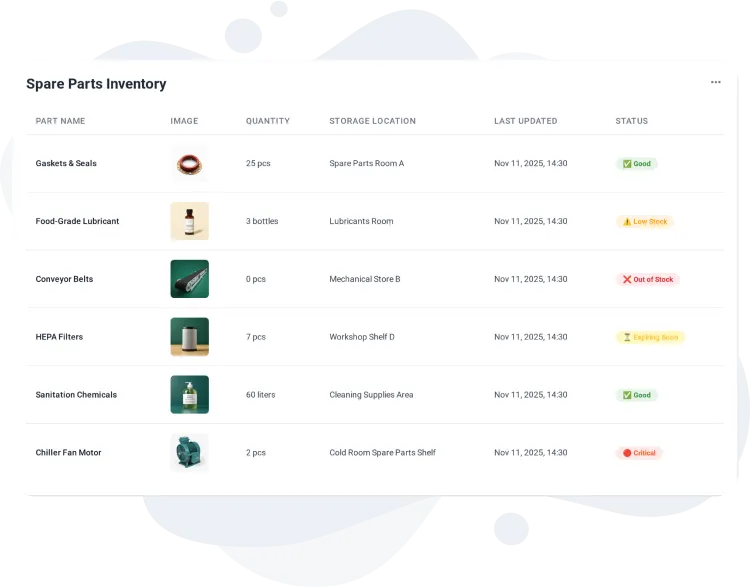

Manage spare parts, sanitation supplies, and critical stock for uninterrupted operations.

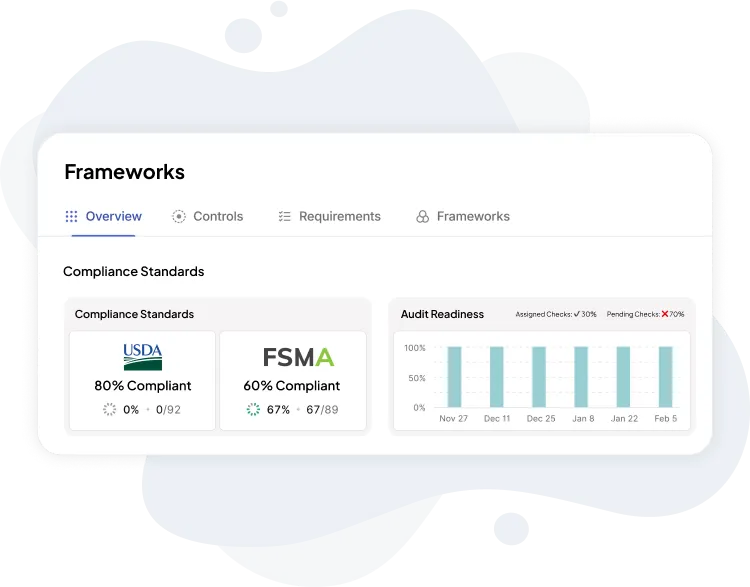

Keep plants audit-ready by enforcing regulations like FDA, USDA, FSMA, HACCP, and GFSI.

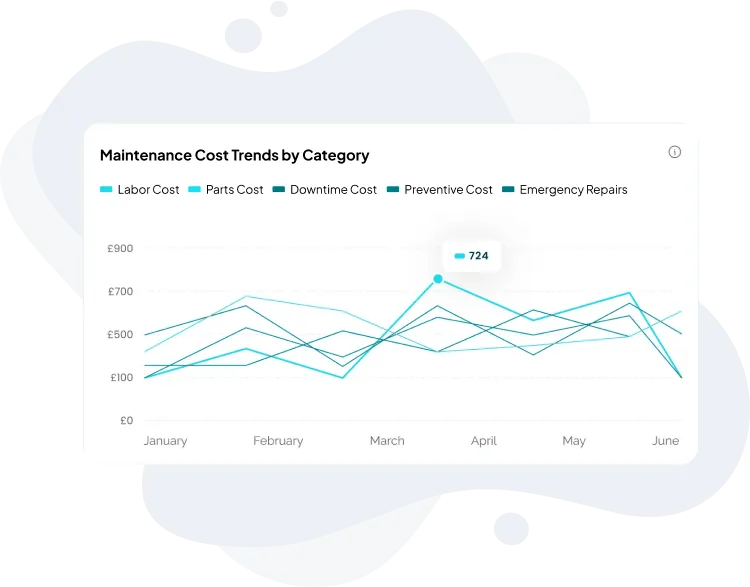

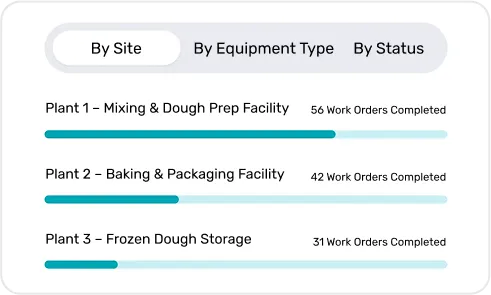

Turn operational data into insights that drive efficiency, compliance, and uptime.

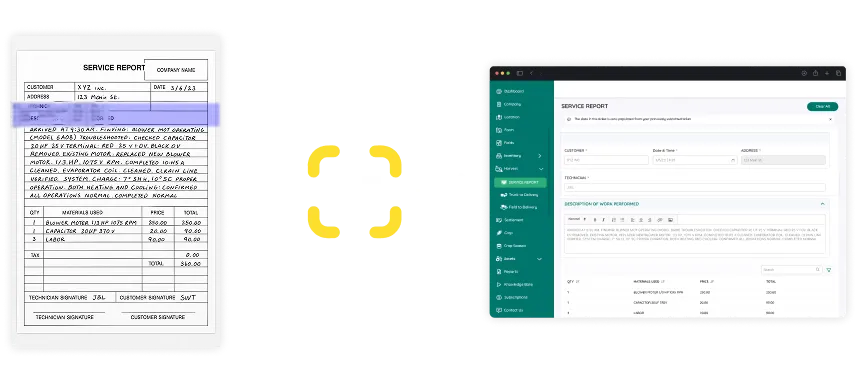

Snap a photo of any paper form, and AI instantly creates a digital, audit-ready record, ensuring accurate equipment history and traceability across your food and beverage plant.

With our food manufacturing plant maintenance software’s advanced feature set, identify failures early to avoid stoppages and maintain food safety.

Get food & beverage maintenance software deployed in three simple steps and protect production

lines with continuous, compliant, disruption-free operation.

Integrate food manufacturing plant maintenance software to break down system silos, ensuring maintenance, QA, and production decisions stay perfectly aligned.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

The plant maintenance management software, often called a CMMS, connects assets, work orders, and compliance into one platform. By combining IoT sensors with AI anomaly detection, it flags risks, like failing chillers, fillers, or conveyors, so maintenance can be scheduled before breakdowns trigger batch losses, safety issues, or missed orders.

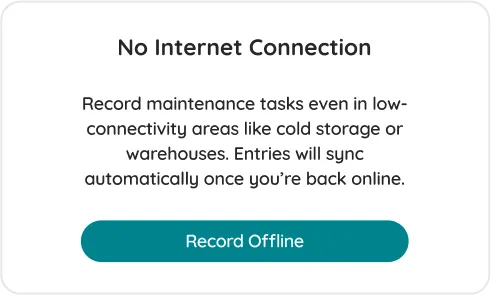

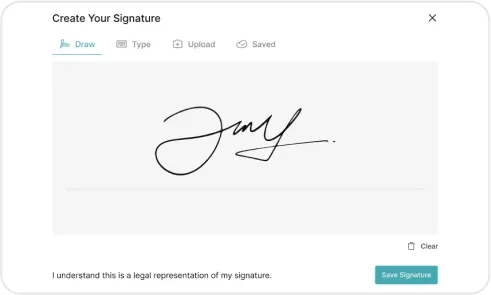

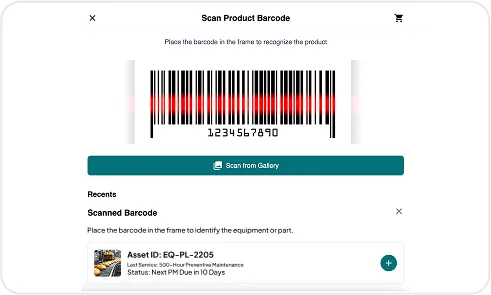

Plant maintenance software for the F&B industry should manage routine plant tasks end-to-end: generating and assigning work orders, scheduling preventive maintenance, tracking parts and spares, and digitizing sanitation or safety checklists. Technicians can update everything from mobile, ensuring real-time visibility for managers and audit-ready records without paperwork.

A preventive maintenance plan should cover lubrication, calibration, cleaning, and safety inspections tailored to each asset type. Fillers require nozzle checks and seal replacements, ovens need temperature calibration, chillers demand refrigerant monitoring, and packaging lines rely on belt alignment and sensor testing. The software automates these schedules, sends reminders, and stores digital proof for audits.

Food and beverage plants face tighter compliance and safety risks than most industries. That means software must provide audit-ready HACCP and FSMA logs, digital sanitation and CIP cycle tracking, temperature and energy monitoring, and mobile-first accessibility in high-humidity or cold storage environments. Out of the box, these are essentials, not add-ons.

Critical features include predictive maintenance with IoT sensors, automated work orders, digital checklists, and role-based alerts. These cuts unplanned downtime and shorten changeovers by ensuring equipment is serviced, calibrated, and production-ready on schedule.

The system provided by Folio3 FoodTech integrates with ERP and quality modules to sync work orders, parts usage, and maintenance events against specific lots or batches. That way, if an audit or recall happens, maintenance history is fully traceable to affected products.

An asset register should track every critical machine, its warranties, service contracts, and maintenance history. Ownership is typically with maintenance teams, but finance and operations depend on it for CAPEX planning and reliability reporting.

It centralizes everything crews need, manuals, SOPs, photos, and digital signatures, directly on each asset profile. Technicians can access instructions instantly, complete checks, and sign off work in a way that’s audit-ready and paperless.

It’s about measuring how well assets perform against throughput, downtime, and quality goals. Findings guide actions like adjusting preventive schedules, targeting underperforming lines, or planning replacements before failures disrupt production.

A complete plan should include sanitation systems, CIP skids, conveyors, packaging lines, refrigeration rooms, and backup power. Software ensures none of these “hidden” assets fall through the cracks during audits or peak production.

Maintenance software built by Folio3 FoodTech lets you build preventive schedules around SKU changeovers, automate line inspections, and trigger rapid calibration tasks. This keeps packaging and fillers production-ready while minimizing downtime between runs.

Digital scheduling automates boiler inspections, combustion checks, and water treatment logs. Predictive monitoring flags efficiency drops early, preventing both energy waste and catastrophic failures that could halt production.