Manage variable-weight batches with catch weight software that keeps yield, pack weights, and order pricing accurate, helping food processors protect margins and reduce costly rework.

Use catch weight management software to gain complete control over variable-weight products, ensuring precise data flow between weighing, costing, production, and financial systems.

Charge for every kilogram you produce, not estimates. Catch weight software helps processors capture true sale weights and stop profit leakage from variable products.

Know the real cost of every batch. Actual recorded weights ensure your inventory reflects trimming, moisture loss, and real yield.

See where product loss happens. Track raw and finished weights to identify shrinkage in cutting, cooking, or packaging before it hurts your margins.

Show your buyers the numbers they can trust. Verified shipment weights and invoices eliminate disputes and strengthen relationships with retailers and distributors.

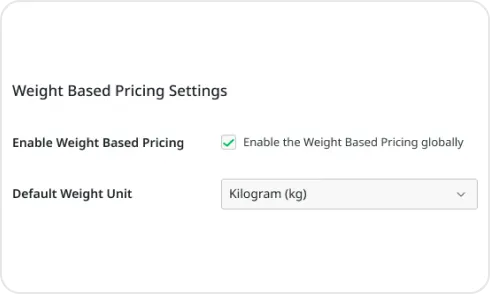

Price your products the way you sell them. Catch weight software supports per-weight, per-case, and blended pricing, keeping every contract accurate and profitable.

Turn every gram into revenue. Compare expected versus actual weights to catch overfills, production loss, and waste before it becomes margin loss.

Control every weight-dependent process with features that connect weighing, costing, and inventory for efficient food production management.

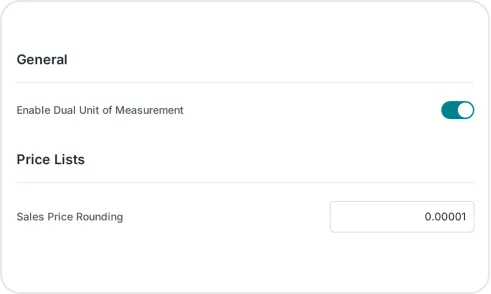

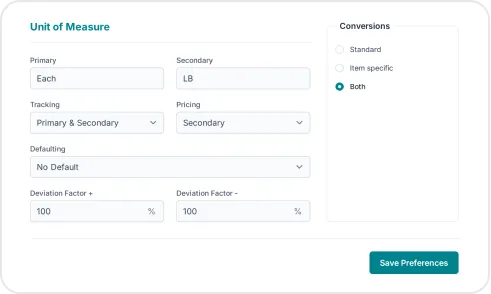

Record and transact in both inventory and catch weight units for precise operational control.

Convert between base and catch weight units in real time to eliminate manual data entry errors.

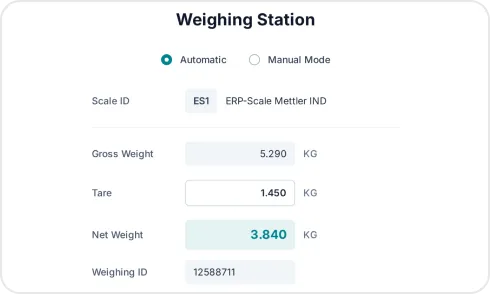

Connect digital scales directly to ERP transactions for live, verified weight recording during processing.

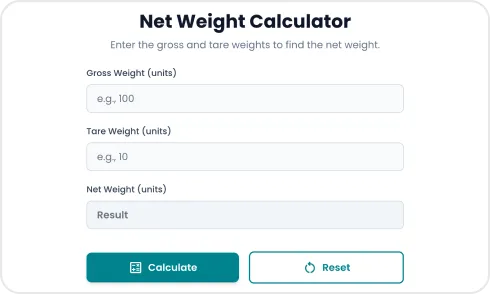

Automatically subtract packaging or container weight to ensure net product weight accuracy in all records.

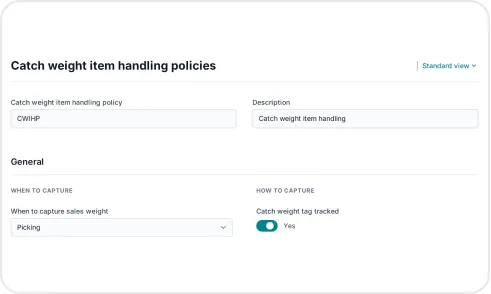

Assign digital tags to record actual item weights and maintain consistency across downstream transactions.

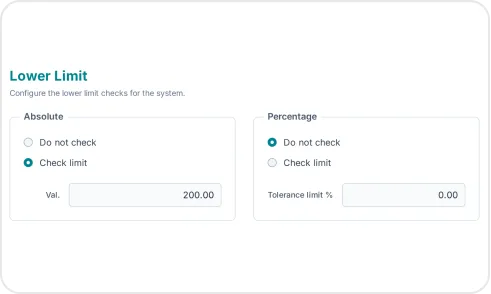

Define acceptable weight ranges and trigger alerts or holds when deviations exceed configured limits.

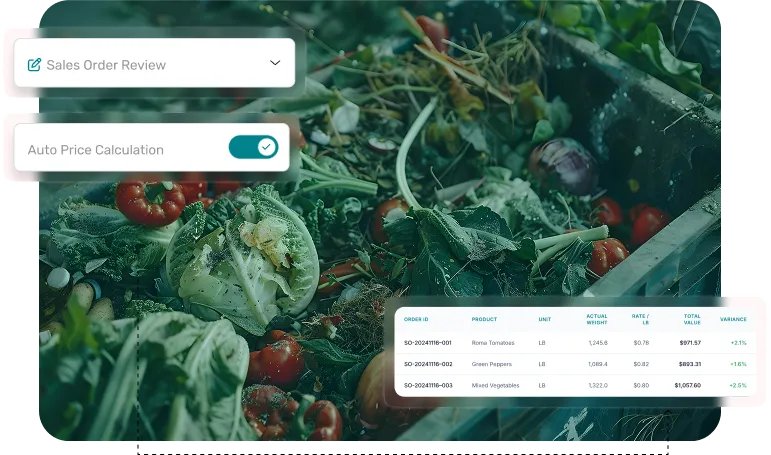

Calculate prices and generate invoices automatically using measured weight data from production and shipment.

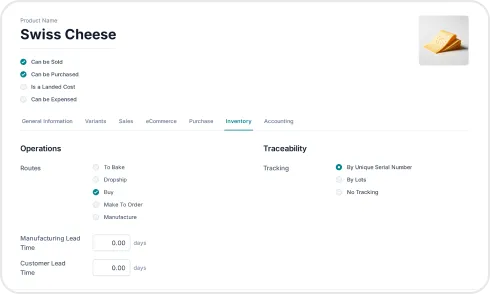

Link recorded weights to specific batches or lots for complete traceability and regulatory compliance.

Analyze input versus output weights to monitor yield efficiency and identify shrinkage or material loss.

Every carcass, block, and carton holds its own value, yet most systems still treat them as averages. Between the plant floor and financial books, small inconsistencies grow into unseen profit loss. The more precisely you weigh, the more accurately you perform. So, how much value could your operation recover with true catch weight control?

Keep every weight-linked cost and sale accurate with industry-grade catch weight software.

Gain full visibility into primal cuts, trim yields, and variable-weight sales using meat catch weight software that keeps costing and margins consistent.

Handle fluctuating bird and portion weights with automated data capture for production output, costing, and compliance.

Use seafood catch weight software to track net weight after glazing, moisture loss, and packaging, and maintain accurate valuation and export compliance.

Manage block and wheel weight variation across curing, packaging, and shipment for consistent costing and margin control.

Monitor case and crate weight fluctuations to ensure fair supplier payments and precise downstream pricing.

Control fill-weight accuracy and finished-goods variance to meet labeling regulations and maintain profit consistency.

Expand from catch weight management to an ERP system that synchronizes every food processing function in real time.

Power Consistency and Control in Every Batch

Streamline recipe management, batch production, and yield control in one connected system. This ERP software, built for food manufacturing, enables operations managers to minimize waste, handle co/by-products, and maintain consistent output quality at scale.

Outcome-driven Benefits

Smarter Stock Control That Protects Margins and Safety

Gain real-time control over stock levels, lots, expiry, and catch-weight items. Designed as an ERP for food manufacturing, this module helps warehouse managers balance safety, compliance, and profitability across dynamic food supply chains.

Outcome-driven Benefits

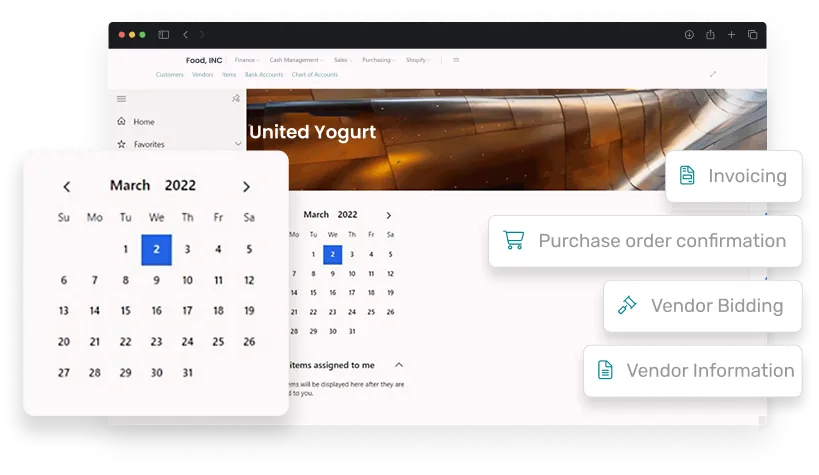

Source Smarter, Spend Better, Stay Compliant

Digitize supplier contracts, approvals, and pricing agreements in one hub. Our ERP system, tailored for food manufacturers, empowers procurement teams to prevent revenue leakage, ensure compliance, and build stronger supplier partnerships through transparency.

Outcome-driven Benefits

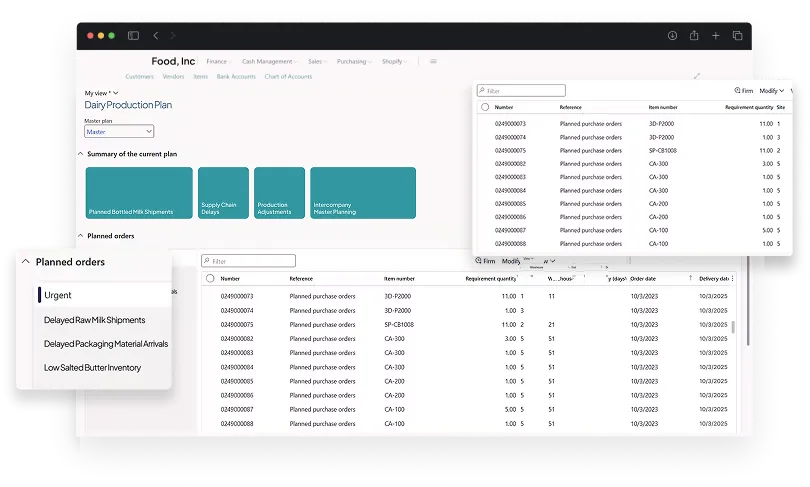

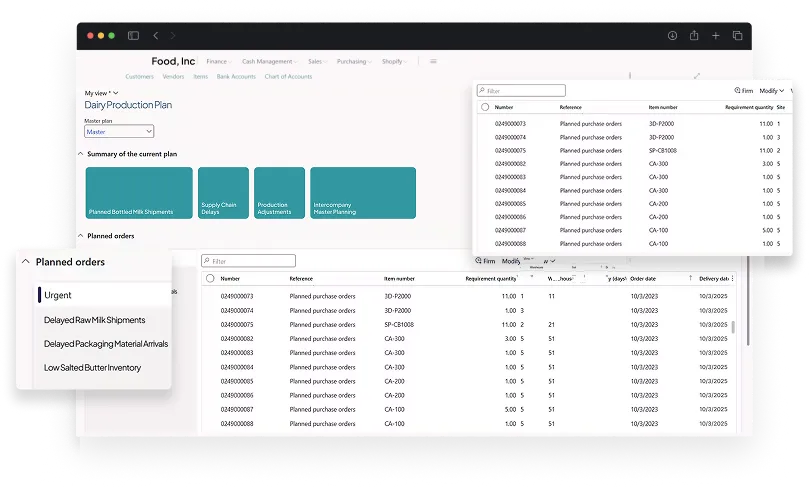

Plan with Precision, Deliver with Confidence

Balance raw material supply with real demand using predictive planning tools. Our ERP system for food manufacturers helps planners reduce shortages, control costs, and maintain production continuity across fluctuating market conditions.

Outcome-driven Benefits

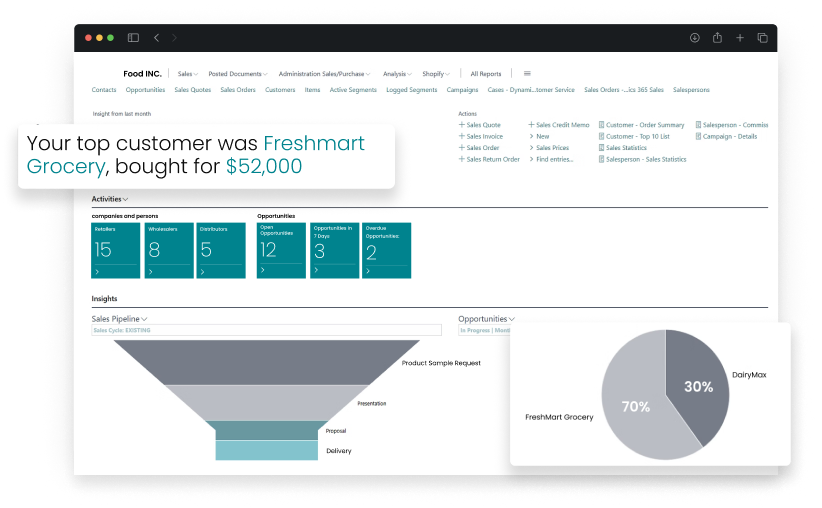

Faster Orders, Happier Customers, Higher Profits

Automate order capture, pricing, and fulfillment to keep customers satisfied. A food manufacturing ERP system like ours ensures sales teams gain visibility across promotions, allocations, and delivery commitments while protecting profitability.

Outcome-driven Benefits

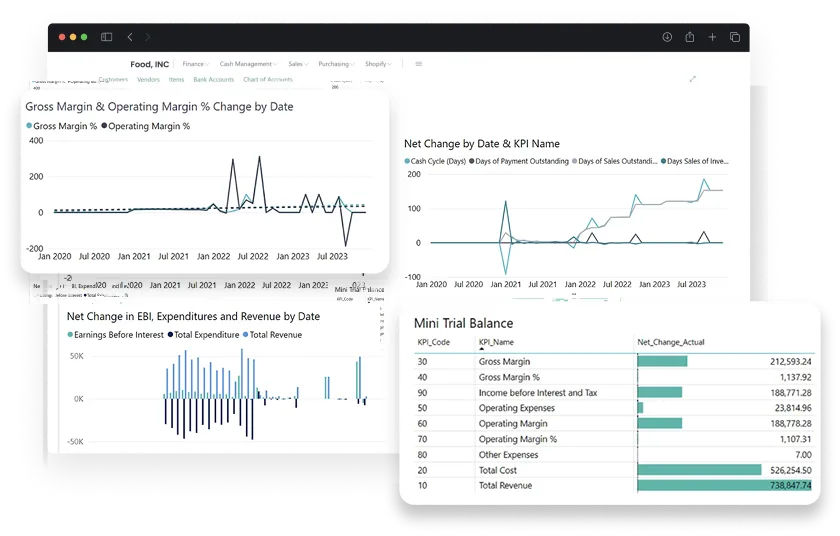

Financial Clarity That Drives Smarter Growth

Consolidate financials, cost tracking, and reporting in one platform. Our ERP software is designed for food manufacturing and equips CFOs to monitor margins, automate compliance, and make better budgeting decisions.

Outcome-driven Benefits

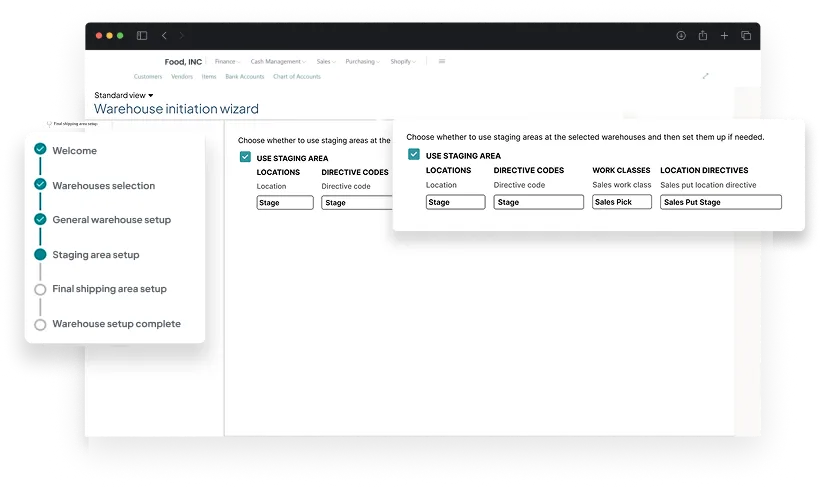

Warehouse Accuracy at the Speed of Food

Digitize warehouse operations with barcode-driven workflows, bin optimization, and FEFO rules. Using our ERP software for the food processing industry, you can ensure accurate storage, efficient picking, and real-time control over goods in cold-chain and ambient environments.

Outcome-driven Benefits

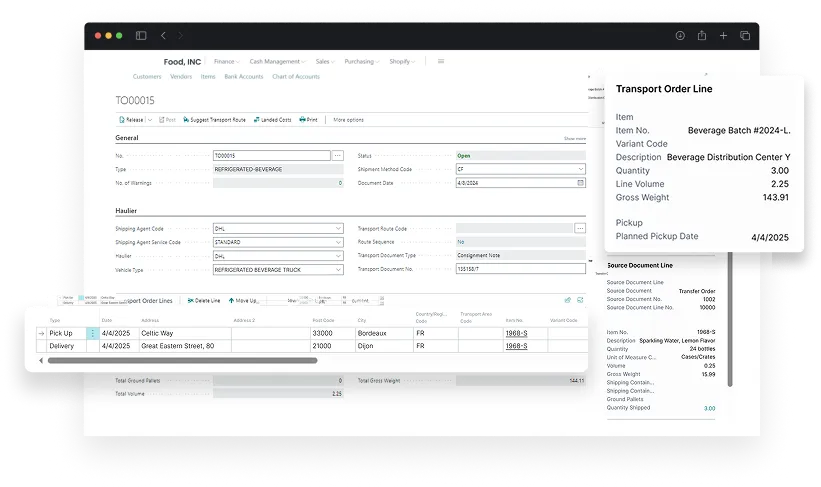

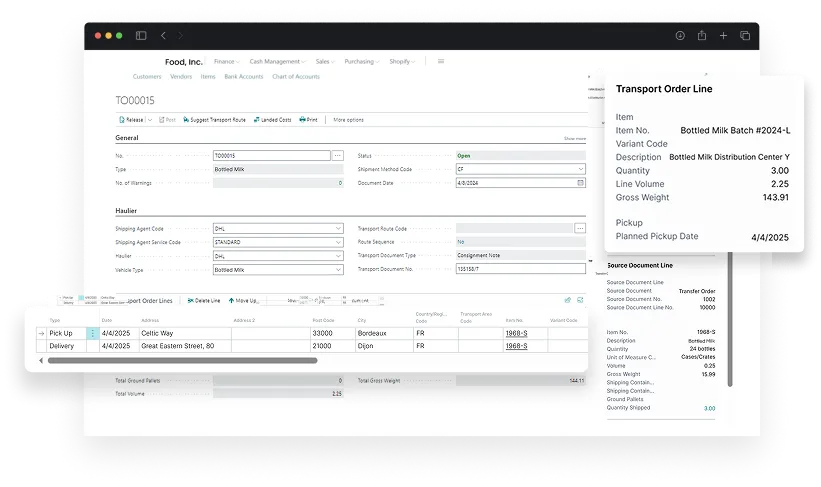

Deliver on Time, Every Time, at Lower Cost

Plan, optimize, and track shipments across fleets and carriers. Our food and beverage ERP software integrates transportation planning with compliance monitoring to cut freight costs while ensuring deliveries remain on time and in condition.

Outcome-driven Benefits

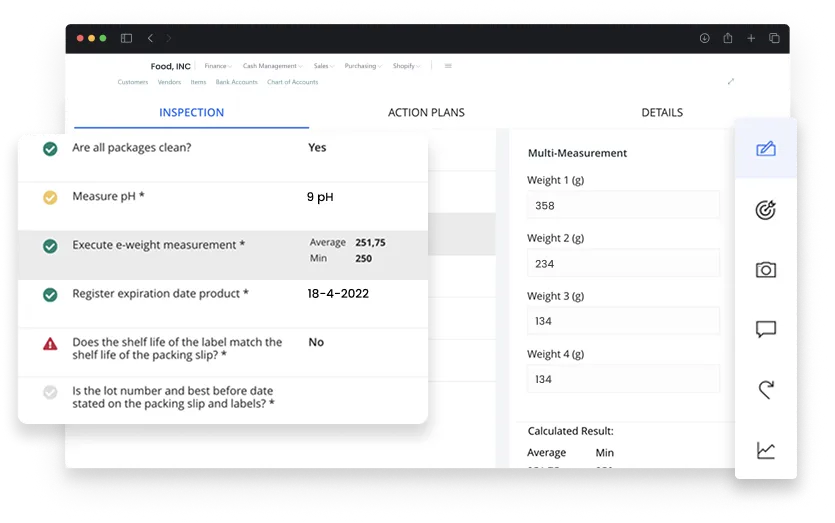

Built-in Quality with Proven Safety Measures

Enforce spec-driven inspections at receiving, in-process, and final, plus non-conformance and CAPA in one hub. Designed as an ERP for food manufacturers, it keeps issues visible early, holds control, and audits evidence ready, so quality becomes assurance, not a checkpoint.

Outcome-driven Benefits

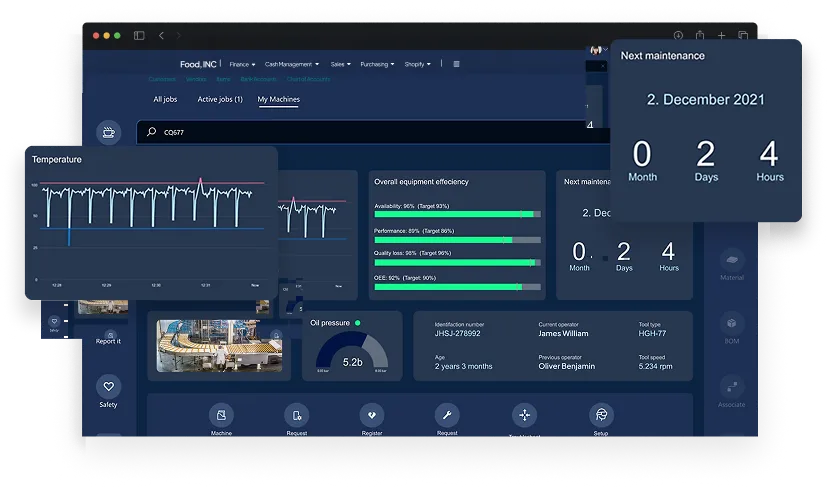

Keep Equipment Reliable, Production Steady, and Costs Down

Schedule preventive and predictive maintenance across production assets to cut downtime. Food ERP systems integrate asset health with operations, giving plant managers full visibility to align equipment reliability with consistent output and regulatory compliance.

Outcome-driven Benefits

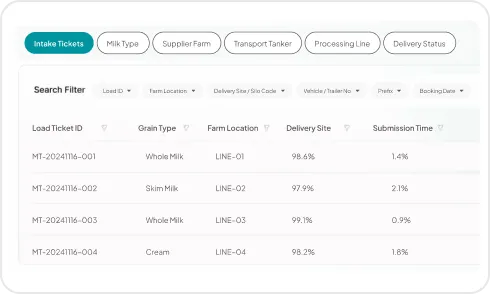

Build Trust and Transparency with Every Grower

Digitize grower intake, grading, and settlement processes for upstream suppliers. Our food and beverage ERP creates transparency by issuing automated statements, helping procurement managers strengthen grower trust while maintaining compliance with industry standards.

Outcome-driven Benefits

Smarter Allocation for Profitable, On-Time Deliveries

Manage allocations, priorities, and fulfillment channels to stabilize service levels. A food distribution ERP empowers planners to balance demand with availability, ensuring customers receive accurate, timely deliveries even under volatile conditions.

Outcome-driven Benefits

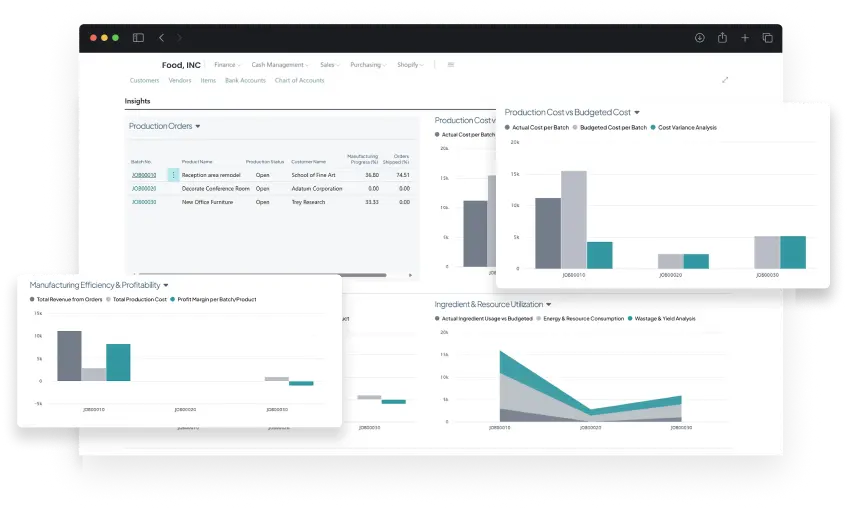

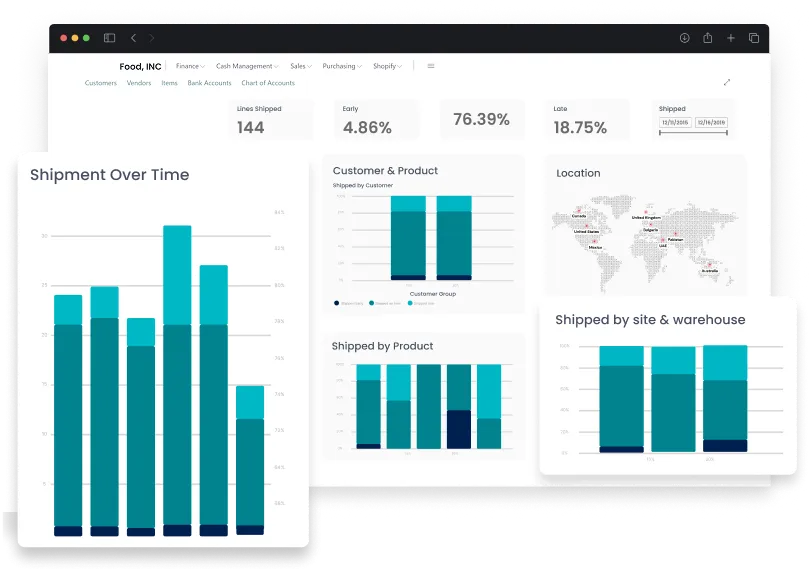

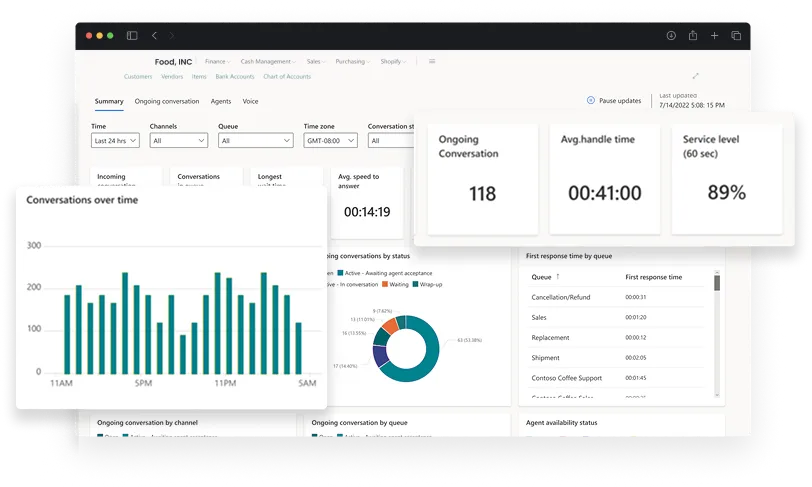

Turn Data into Decisions That Drive Performance

Turn operational data into real-time insights with dashboards, KPIs, and predictive analytics. This food production ERP module equips managers with self-service tools to track performance, identify inefficiencies, and guide smarter, faster business decisions.

Outcome-driven Benefits

See how we turn challenges into breakthrough solutions for our clients.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

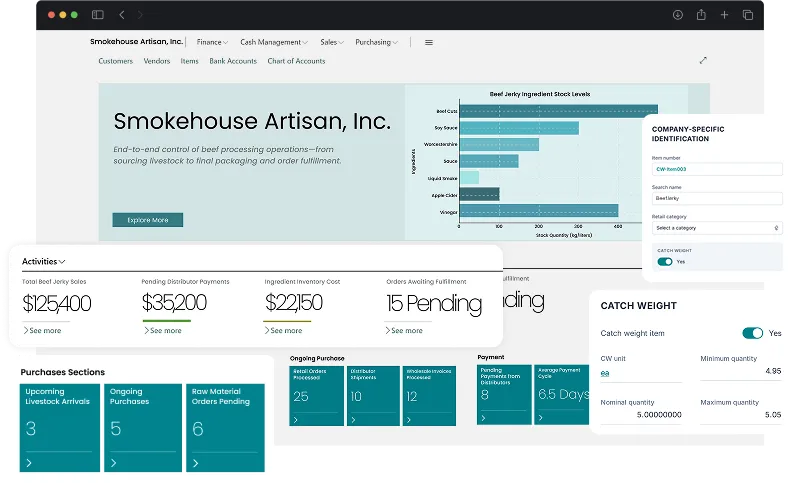

Software for managing catch weight allows processors to manage products sold by both a fixed unit (like cases) and a variable unit (like weight). It records both measures simultaneously, so when a pallet is received, produced, or shipped, the ERP captures total cases and their actual combined weight. This ensures costing, pricing, and inventory all reflect real product data rather than averages.

Food ERP by Folio3 FoodTech automatically links the ordered quantity to the actual shipped weight by integrating live scale data at every stage. When the product is weighed, the system recalculates totals and applies accurate pricing based on the verified catch weight.

A robust ERP connects directly with floor scales, inline weighers, and label printers to capture and record real-time product weights. Integration with WMS and shop floor systems ensures those readings automatically update production orders, inventory counts, and outbound documentation.

List products online by a consistent unit, like “price per pound”, while clearly displaying average case weight ranges. When the order ships, your ERP captures the exact catch weight from the scale and automatically recalculates the invoice total. This keeps storefront pricing transparent while ensuring customers pay only for the actual weight delivered.

Folio3 FoodTech ERP assigns a unique GS1 barcode to each case, embedding both the lot or batch ID and its actual catch weight. As products move through production and distribution, each scan automatically updates ERP records with verified weight and trace data. This ensures processors can trace back any case to its origin, production line, and shipment details in seconds.

It depends on your operation’s flow. “Weigh at pick” works well for pre-packed products with stable weights, while “weigh at pack” fits fresh-cut or portioned items. Many processors use a final weigh-and-label step for accuracy, ensuring the last recorded weight drives the invoice, shipment, and traceability data.

Operations teams rely on yield, shrink, and production variance reports to track where weight is gained or lost. Finance needs margin-per-pound, freight-by-weight, and cost-to-serve reports to see how variability impacts profitability. A strong catch weight ERP connects both, linking operational weights directly to financial outcomes.

Each case label pulls real weight data from the ERP and embeds it alongside mandatory details like nutrition facts, allergens, and lot numbers. The system prints compliant labels automatically as soon as the product is weighed and packed. This reduces labeling errors and ensures every shipment meets regulatory and retailer requirements.

The ERP captures input weights at every stage, from raw intake to finished packs, and compares them against output data. Moisture loss, trim, and rework are recorded automatically, giving processors a live view of actual yield performance. This lets costing reflect the real product weight, not assumptions, for accurate margins and process control.