Navigate complex regulations like FSMA, FSMA 204, and cGMP while achieving top certifications, including GFSI, BRCGS Food Safety, BRC Food, SQF, ISO 22000, and USDA. Leverage advanced tools to manage suppliers, automate audits, ensure fast HACCP compliance, and meet FDA, State, and USDA standards with confidence.

Ensure the integrity of your food journey with specialized software solutions, safeguarding every link in the supply chain for optimal safety and compliance

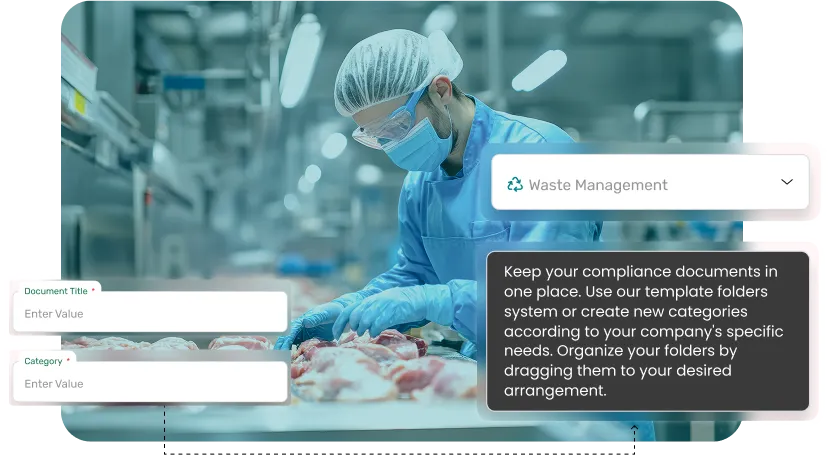

Paper-based or scattered documentation systems make it challenging to maintain accurate records, increasing risks of non-compliance and inefficiencies.

Disconnected systems make it difficult to trace a product’s journey, delaying responses to recalls and compliance inquiries.

Inconsistent management of allergens, raw materials, and ready-to-eat products can lead to cross-contamination and foodborne illnesses.

Inadequate monitoring of temperature-sensitive storage and transport can lead to product spoilage and safety issues.

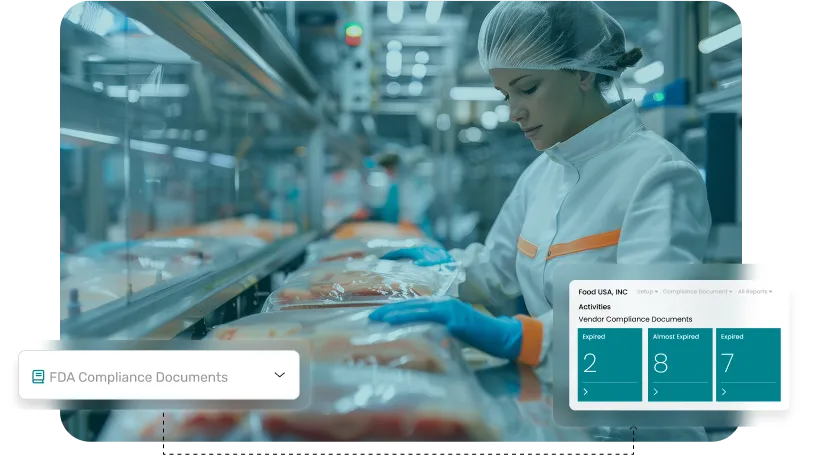

Keeping up with evolving food safety regulations across regions is time-intensive and error-prone.

Missed or incomplete sanitation processes increase the risk of contamination, fines, and brand damage.

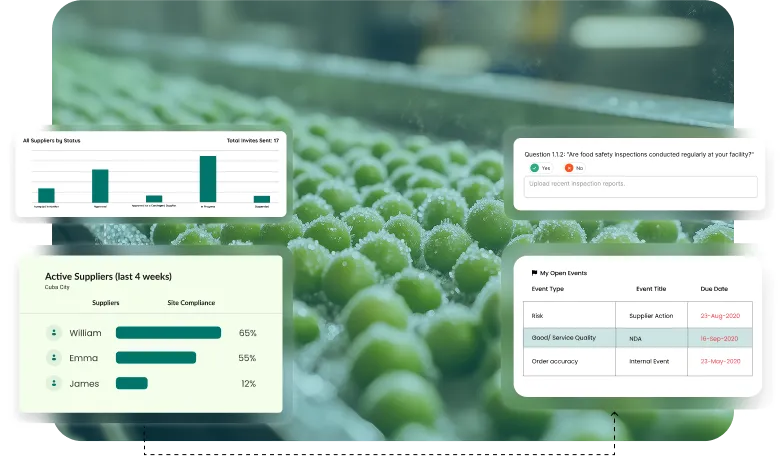

Insufficient visibility into supplier compliance or transport conditions leads to higher risks of unsafe products entering your system.

Delayed actions during incidents like contamination or spoilage can result in serious financial and reputational losses.

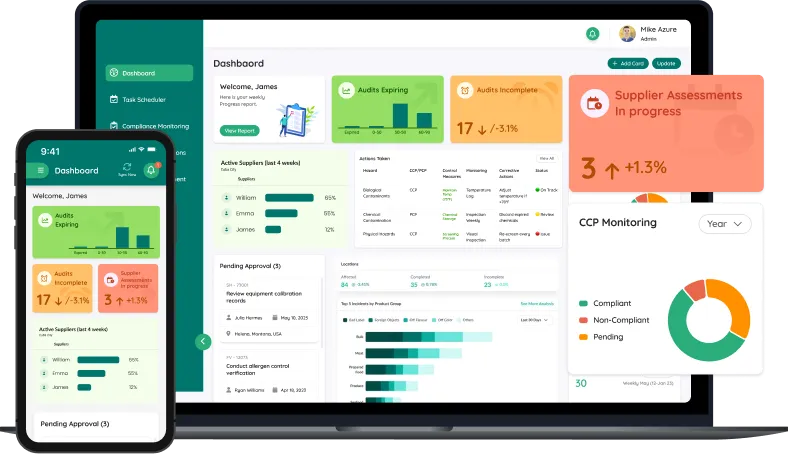

Ensure seamless compliance, quality, and safety across your entire food operation. Our Food Safety Software empowers food producers, processors, packers, distributors, and retailers to streamline food safety, manage compliance effortlessly, and elevate product quality—all in real time.

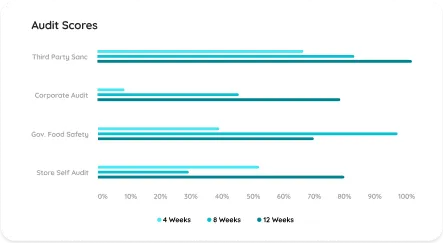

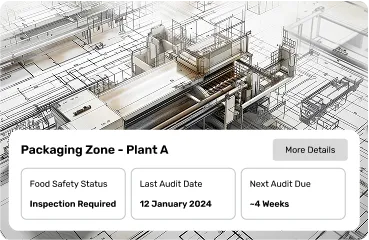

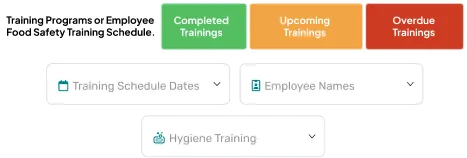

Maintain regulatory compliance with our Food Safety Software, track certifications (like HACCP, FSMA, and ISO 22000), manage food safety audits, and ensure seamless adherence to industry standards.

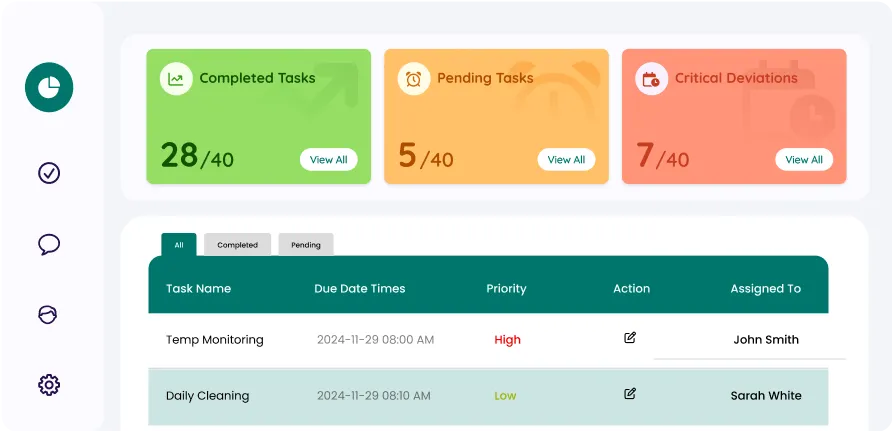

Ensure every food product meets the highest standards. Automate quality checks, track deviations, and maintain consistency across all production batches with real-time monitoring.

Build a reliable supply chain by tracking supplier performance, ensuring ingredient quality, and maintaining strong supplier relationships to reduce risks and enhance compliance.

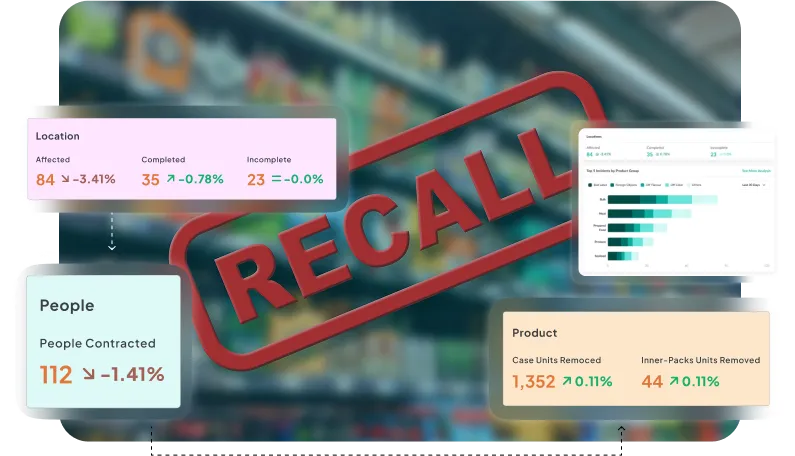

Quickly identify and isolate affected products, minimize recall impact, and safeguard your brand’s reputation. Stay prepared with real-time recall management tools.

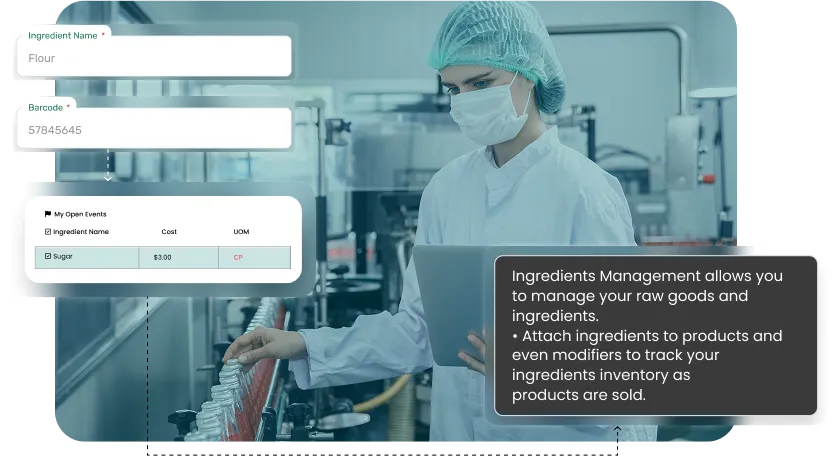

Track and manage ingredients with real-time inventory control. Adapt formulations, ensure seamless traceability, and minimize waste through precise batch processing for a more efficient, compliant, and cost-effective food production process.

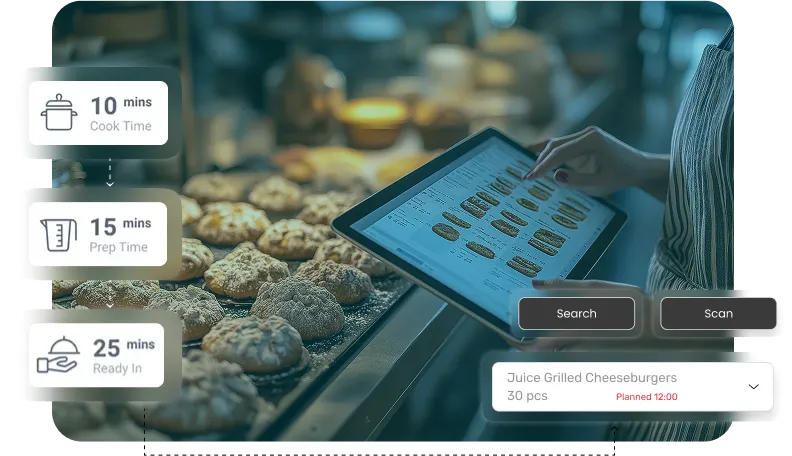

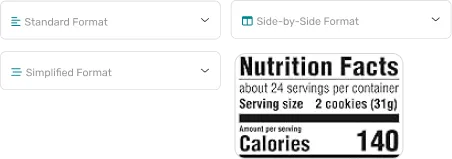

Standardize and digitize recipes for consistent quality and compliance. Track allergens, nutrition, and costs while optimizing ingredient usage, streamlining batch production, and improving efficiency across food manufacturing operations.

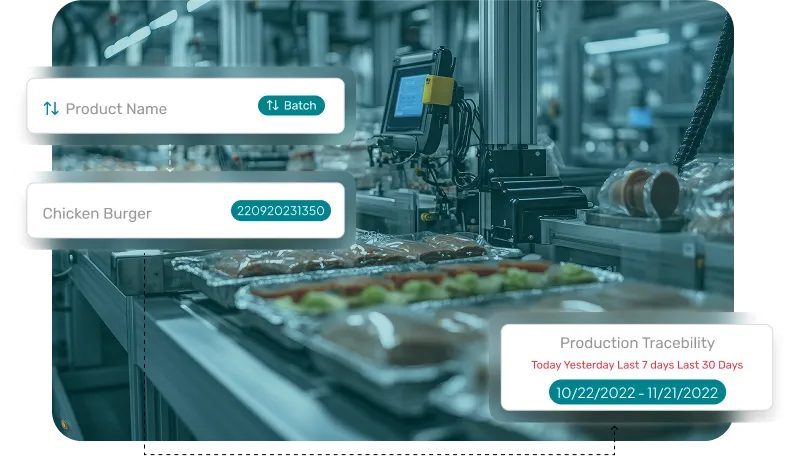

Ensure full traceability from sourcing to consumption with real-time tracking. Improve recall readiness, maintain compliance, and gain complete visibility across the supply chain to enhance food safety and transparency.

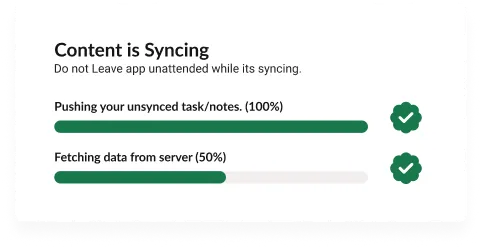

Automate documentation and audits for effortless compliance. Maintain structured workflows, keep records audit-ready, and ensure regulatory adherence while streamlining food safety inspections and quality control processes.

Ensure seamless compliance with software that automates food safety processes, tracks certifications, and keeps audit-ready documents organized

From procurement to distribution, optimize your food business with ERP solutions built to meet the industry's unique demands, driving efficiency and supporting growth at every step.

Safeguard every step, from milk collection to pasteurization and cold storage, while meeting food safety regulations and maintaining product quality.

Ensure consistent quality with raw material tracking, precise carbonation control, and integrated safety checks.

Preserve product integrity by monitoring freezing processes, optimizing cold storage, and managing delivery logistics efficiently.

Streamline baking workflows with effective ingredient management, quality control, and waste reduction measures.

Achieve consistent results with accurate ingredient tracking, batch uniformity, and scalable safety protocols.

Maintain freshness and safety with optimized temperature management, proper inventory rotation, and reliable supplier tracking.

Enhance traceability and compliance by managing workflows, monitoring weights, and ensuring food safety at every stage.

Deliver consistent quality through precise recipe management, streamlined ingredient sourcing, and optimized safety measures.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

Stop juggling multiple tools to monitor food safety processes, ingredient stocks, or compliance data. Centralize all your food safety operations—track batches, manage inventory, and ensure regulatory compliance seamlessly with our Food Safety Software.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

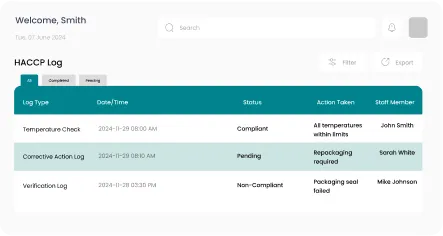

Folio3 FoodTech food safety software helps food teams digitize HACCP based programs, daily monitoring, corrective actions, verification, and records so compliance stays consistent and audit ready across operations.

No. FSMA does not require software, but it does require covered facilities to have and implement a written food safety plan with hazard analysis and risk based preventive controls. Folio3 FoodTech helps teams manage these requirements with structured workflows and centralized records.

Folio3 FoodTech helps teams maintain audit ready documentation such as HACCP or preventive controls plans, monitoring logs, corrective actions, verification activities, and supporting evidence in one system.

Folio3 FoodTech supports audit readiness by organizing the evidence auditors typically expect, including internal audits, CAPA workflows, document control, monitoring records, traceability records, and verification history.

CAPA means corrective and preventive action. Folio3 FoodTech helps teams log nonconformances, identify root causes, assign actions, track completion, and retain verification evidence for audits and continuous improvement.

With Folio3 FoodTech, supplier compliance documents can be centralized, requested through workflows, tracked for missing or expired items, and routed for review and approvals so teams stay audit ready without email chasing.

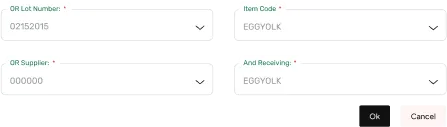

FSMA 204 is the Food Traceability Rule for certain foods. Folio3 FoodTech supports traceability readiness by helping teams link lots, events, and documents so traceability records can be created, maintained, and retrieved quickly when needed.

Critical tracking events are defined supply chain steps where traceability records are required, and key data elements are the required data points captured at those events. Folio3 FoodTech helps teams structure data capture around these events so traceability information stays consistent across operations.

Folio3 FoodTech digital forms create searchable, timestamped records, reduce missed fields through structured inputs, and speed up audits by making evidence easy to retrieve, review, and share.