Detect contamination hotspots before they impact food quality. Track microbial risks, verify sanitation, and avoid food spoilage with purpose-built environmental monitoring software for food manufacturers.

Address contamination threats, inconsistent sanitation, and data gaps with proactive monitoring and corrective actions.

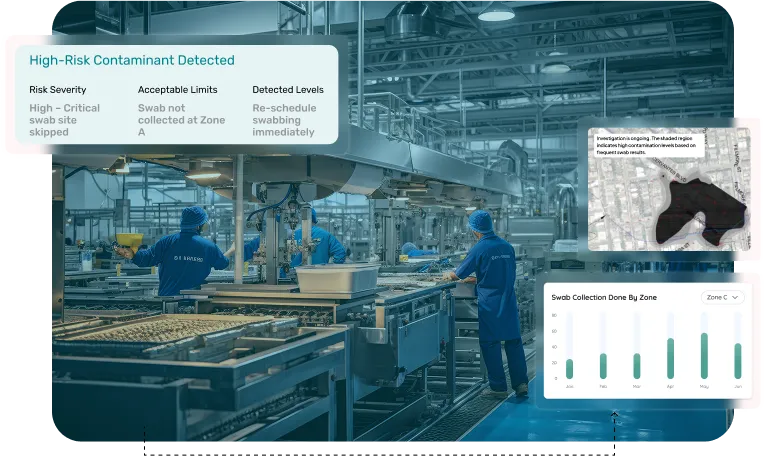

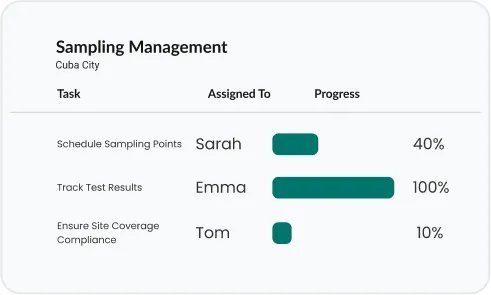

Without a strategic swab site sampling plan, critical areas may go untested, leading to inaccurate pathogen data and ineffective sanitation validation.

Inconsistent testing and poor documentation make it difficult to pinpoint where contamination started, causing delayed corrective actions and prolonged safety risks.

Without a structured approach, CAPAs are often overlooked. Manual workflows and missed follow-ups can result in recurring contamination risks and unresolved food safety issues.

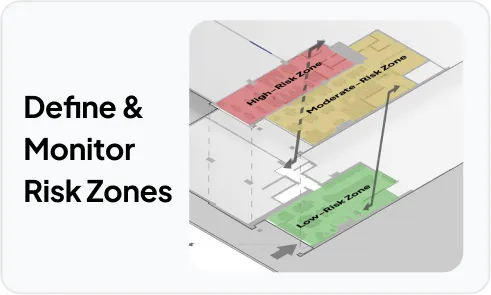

Frequent movement of people and equipment spreads contaminants across critical zones. Without proper monitoring, high-risk areas become breeding grounds for cross-contamination.

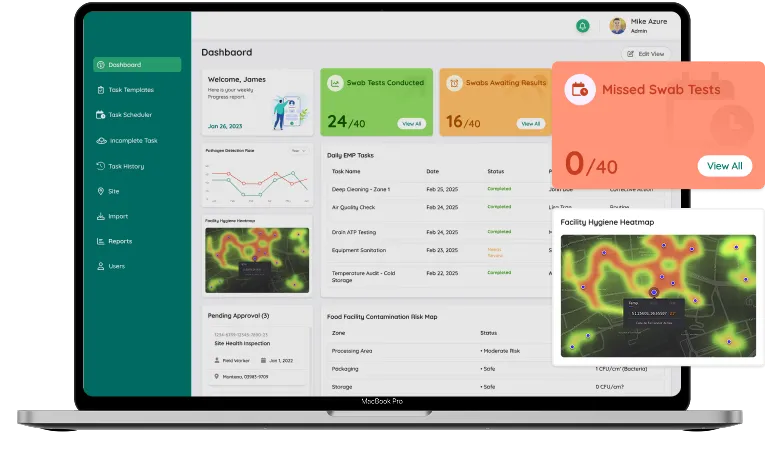

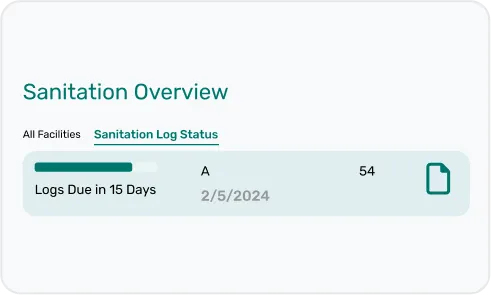

Monitor every zone, detect risks, and fully comply with real-time environmental monitoring software for food manufacturers.

Protect your food manufacturing facility with environmental monitoring software designed for precise tracking and rapid response.

See how we turn challenges into breakthrough solutions for our clients.

Protect your products and reputation with a comprehensive approach to food safety, from risk detection to corrective action.

Keep up with FDA, FSMA, HACCP, and local regulations without the manual hassle. Automate tracking, simplify audits, and maintain compliance at every step.

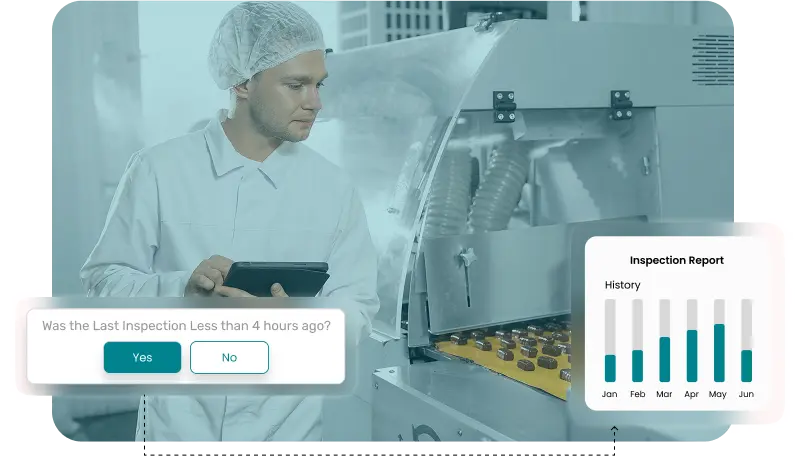

Run strict quality checks at every stage—raw materials, production, and final products. Catch issues early to reduce waste and maintain consistency.

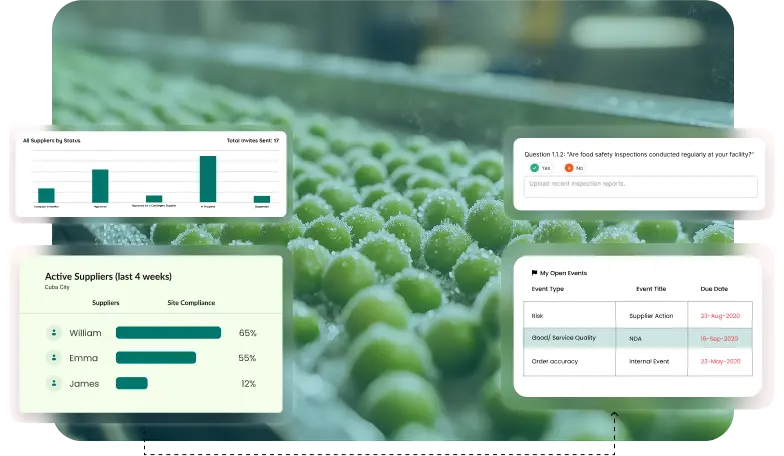

Continuously assess supplier performance against food safety and quality benchmarks. Automate documentation reviews, track certifications, and flag non-compliance risks.

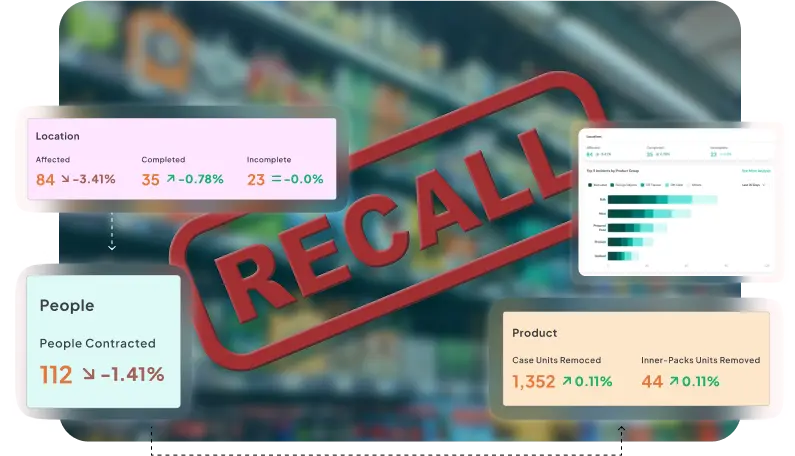

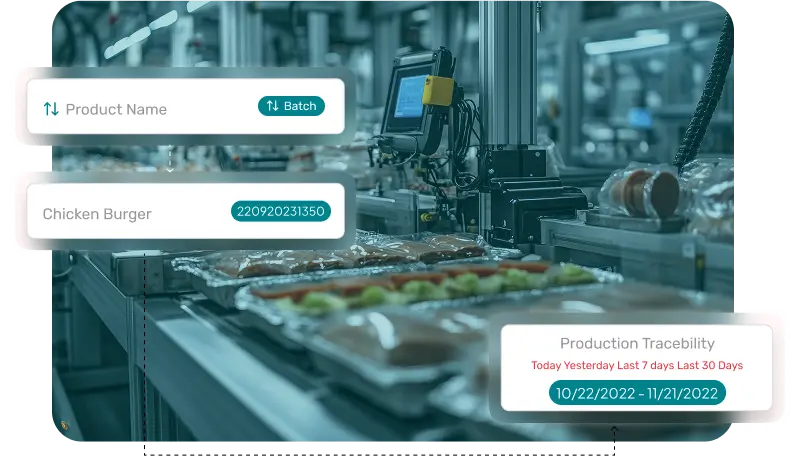

Act fast when contamination strikes. Instantly trace affected batches, trigger automated recall workflows, and alert key stakeholders to minimize impact.

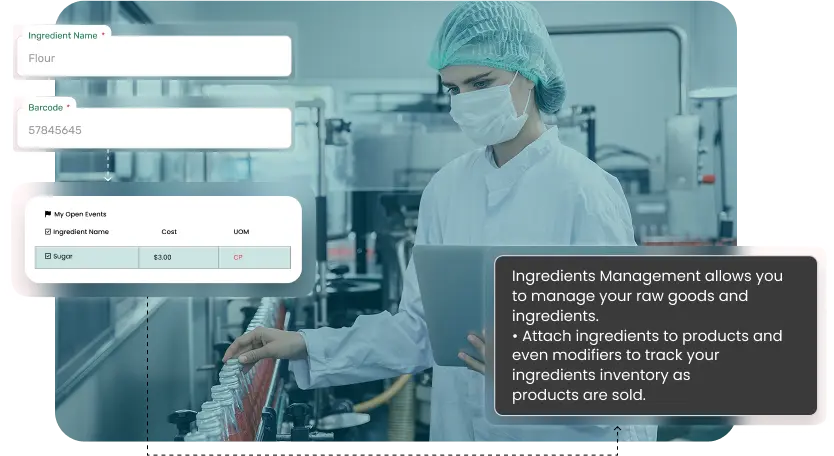

Track every ingredient from sourcing to production. Prevent cross-contamination, enforce allergen controls, and ensure regulatory compliance with detailed records.

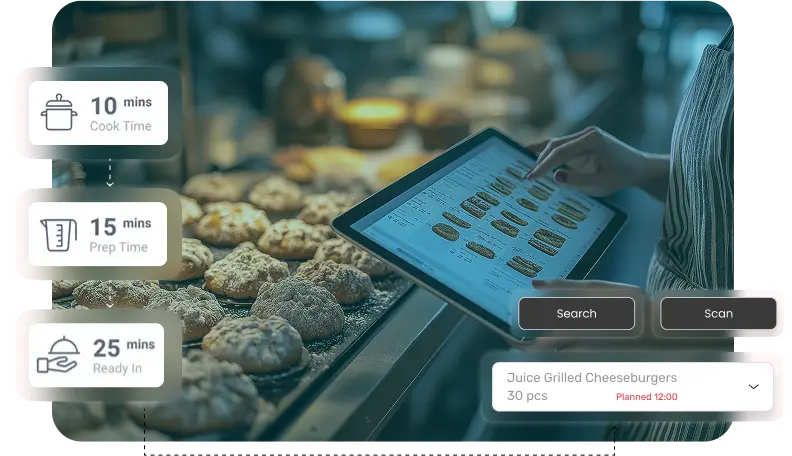

Maintain recipe integrity with precise tracking of ingredient ratios, nutritional values, and batch consistency. Prevent formulation errors that impact safety and quality.

Monitor every movement of ingredients and finished products across the supply chain. Enable fast root-cause analysis and targeted recalls to contain contamination risks.

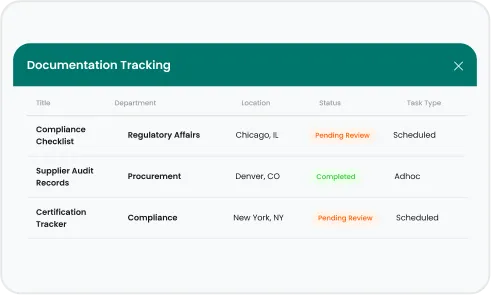

Digitize safety records, supplier agreements, and compliance reports in one system. Automate audit readiness with version-controlled documentation & real-time access.

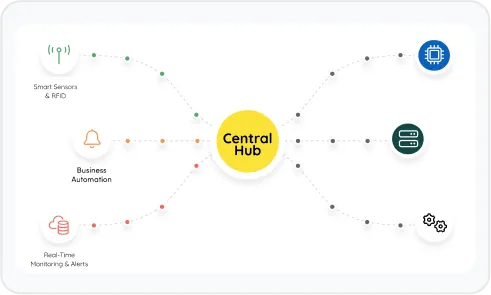

Eliminate fragmented data by integrating environmental monitoring software for food manufacturers with your facility’s digital ecosystem.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Environmental monitoring in the food industry refers to systematic sampling and testing of the production environment to detect contaminants and ensure food safety and environmental monitoring compliance. This process helps food manufacturers meet regulatory requirements and maintain product quality.

It automates data collection, analysis, and reporting, ensuring compliance with industry regulations such as FSMA and HACCP. By continuously monitoring environmental conditions, food manufacturers can proactively detect and mitigate risks, strengthening their environmental monitoring food safety protocols.

A comprehensive environmental monitoring program food safety includes:

The environmental monitoring procedure in the food industry typically involves swabbing surfaces, air sampling, and testing for pathogens like Listeria and Salmonella. The results are logged in the software, which helps track trends, detect anomalies, and generate compliance reports.

Yes, it integrates seamlessly with ERP, MES, and QMS systems, allowing food manufacturers to link their environmental monitoring plan for food industry with production data, quality control, and compliance tracking.

Food environmental monitoring is critical for regulatory compliance with FSMA, FDA, and GFSI standards. An environmental monitoring program food safety ensures that facilities maintain proper hygiene, control contamination risks, and provide audit-ready reports.

Advanced software leverages AI and IoT to analyze environmental trends, predict contamination risks, and optimize environmental monitoring for food processes. This proactive approach helps food manufacturers prevent quality issues before they arise.

Yes, leading EMP software solutions offer customization options to align with specific food manufacturing processes, facility layouts, and compliance needs. Whether it’s a bakery, dairy plant, or meat processing facility, the software adapts to different environmental monitoring in food industry requirements.

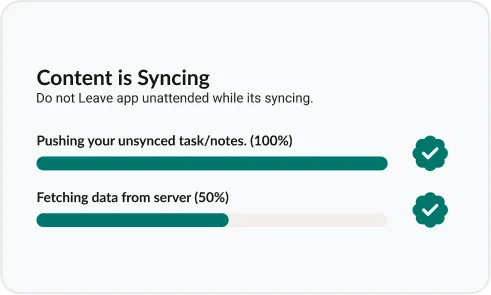

EMP software captures real-time sensor data, laboratory results, and manual inputs. If contamination thresholds are exceeded, the system triggers alerts, allowing food safety teams to take immediate corrective action as part of their environmental monitoring program.